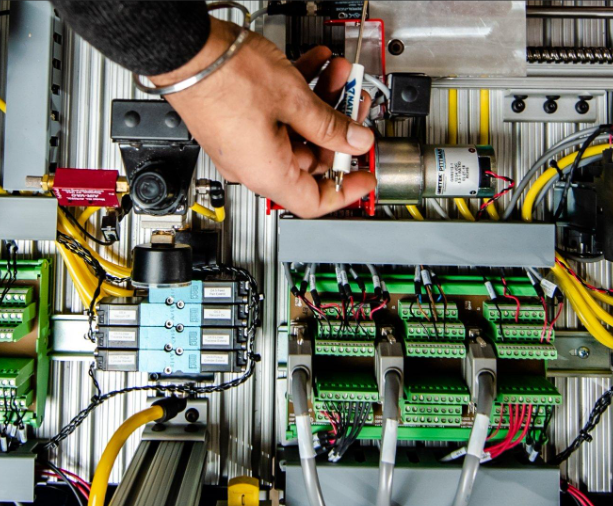

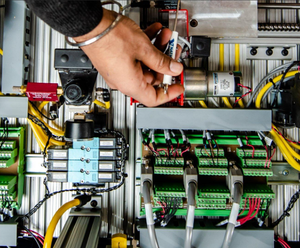

What inspections are included in the electronic and electrical goods inspection? Inspection and factory visit inspection services

As a professional third-party inspection and testing agency, we are dedicated to providing comprehensive quality assessment and certification services for electronic and electrical products. Through strict inspection procedures and professional testing standards, we ensure that every product complies with industry norms and customer requirements. The following is the detailed inspection and certification standard system for electronic and electrical products.

I. Process and Procedure Inspection Certification Standards

1. Certification Objectives

Establish a comprehensive process quality certification system, clearly define standardized execution norms for acceptance and rejection, and provide authoritative basis for product quality control.

2. Scope of Application

Incoming material quality inspection certification

Process Quality Control Certification

Final product factory inspection and certification

3. Process Inspection and Certification Specifications

3.1 Plate Quality Certification

3.2 Drilling Process Certification

3.3 Line Precision Certification

3.4 Resistance Welding Performance Certification

3.5 Identification Character Certification

3.6 Carbon Oil Process Certification

3.7 Forming Process Certification

3.8 V-CUT Process Certification

3.9 Blue Film Application Certification

3.10 Rosin Process Certification

3.11 Other Special Certifications

Certification processing: Non-compliant materials are returned to the supplier, semi-finished products/finished products are sent to MRB for processing, and ensure the integrity of the quality traceability system.

II. Inspection and Certification of Printed Circuit Board Technology

1. Certification Objectives

Establish a quality certification system for printed circuit board printing processes to ensure that the products meet the customer's requirements and international standards.

2. Certification Scope

This certification covers the entire process of quality control for both single-sided and double-sided printed circuit boards, including incoming material inspection and new material trial certification.

3. Document Validity Level Certification

3.1 Technical Requirements of Order Contract

3.2 Specifications for Customer Information and Drawings

3.3 Special Requirements of Customer SPEC

3.4 Internal Process Standard System

3.5 International Standard IPC-A-600F

Through a multi-level file verification system, ensure that product quality meets all standards comprehensively.

III. Final Inspection and Certification Standards

1. Inspection Instrument Certification

10X magnifying glass

Precision caliper measuring tool

3M Professional Test Tape

Alcohol cleaning solution

Surgical blade

Green oil detection pen

Special adhesive tape

Small brush pen

All testing instruments must be calibrated regularly to ensure the accuracy of the inspection and certification.

2. Inspection Process Certification

The final inspection is carried out by the FQC professional team.

FQA conducts sampling review and certification

40W standard fluorescent light box light transmission inspection

Establish a complete inspection record system

IV. Inspection and Certification Process Standards

1. Sampling Inspection Plan

Implement statistical sampling in accordance with international standards

Key performance items undergo full inspection and certification.

Establish a quality traceability management system

2. Environmental Certification for Inspection

Standardization of Inspection Laboratory Environment

Calibrated and qualified testing equipment

Strictly follow the inspection operation procedures

3. Defect Level Certification

Fatal Defect: Zero Tolerance for Safety Issues

Serious defect: Strict control over functional failure

Minor defect: The appearance issue is within the acceptable standard.

V. Key Control Matters for Factory Inspection Certification

To ensure that the quality of electronic and electrical products continuously meets the certification requirements, during the factory inspection process, the following key control matters need to be addressed:

Supply chain quality certification: Establishing a supplier quality assessment system

Production process control: Establish operation standards for key processes

Equipment management for detection: Regular calibration and maintenance of instruments

Personnel qualification certification: Professional training for inspection personnel

The document system is well-established: quality records are complete and traceable.

VI. Professional Inspection Service Certification

1. Inspection Report Certification

Provide professional inspection assessment reports

Detailed analysis of quality issues

Improvement Suggestions and Solutions

2. Service Commitment Certification

Thoughtful and professional customer service

Timely and accurate inspection feedback

Continuous quality improvement support

Inspection Certification Summary

The inspection and certification of electronic and electrical products is a systematic process that requires comprehensive verification from raw materials, production processes to final product quality. By establishing a professional inspection system and strict quality standards, we ensure that every product meets the industry certification requirements, providing customers with reliable quality assurance.

分享这个商品

What inspections are included in the electronic and electrical goods i

A professional third-party inspection and testing agency, we are dedicated to providing comprehensive quality assessment for electronic and electrical products.