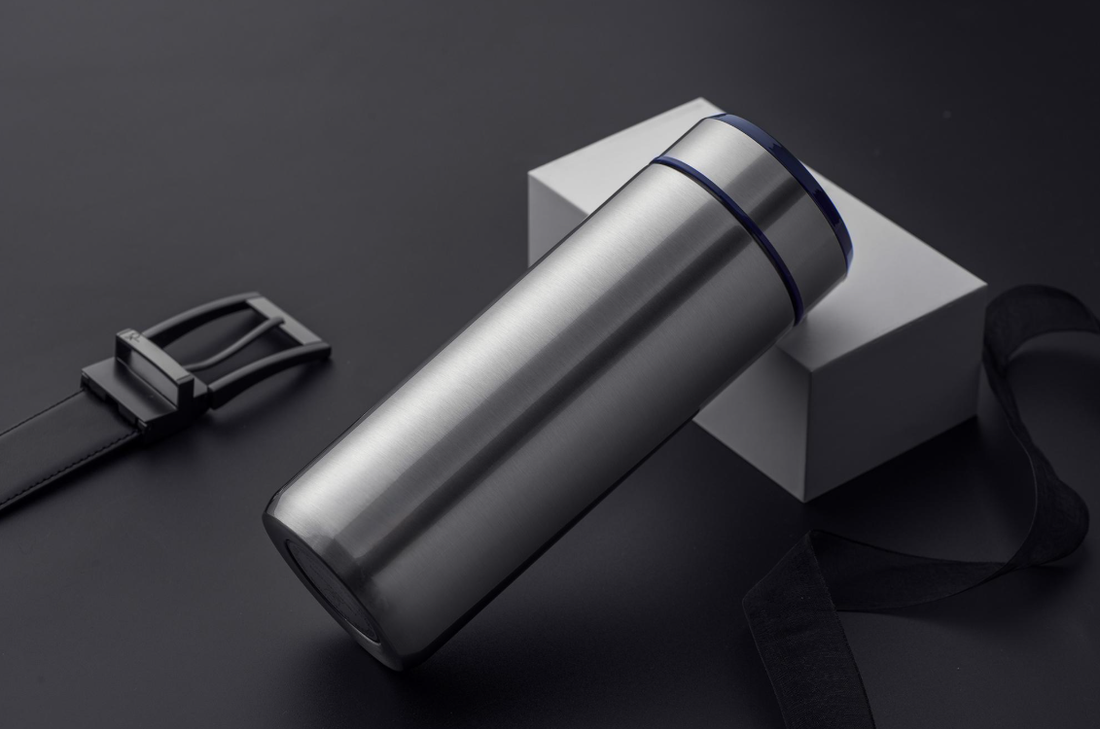

Inspection and testing standards for insulated cups Inspection and factory verification services

The insulated cup, as a daily drinking vessel, its quality directly affects the safety of use and health protection. For purchasers, brand owners, and quality control professionals, establishing a complete supplier evaluation system and product acceptance standards is of utmost importance. This article will systematically elaborate on the quality inspection standards for insulated cups, the production monitoring process, and professional inspection methods.

I. Source Control: Key Points for Factory Evaluation of Thermal Cup Manufacturers

Before making bulk purchases, conducting a comprehensive review of the manufacturer's qualifications is the foundation for ensuring product quality.

Production qualification certification:

Has the factory obtained the ISO9001 quality management system certification?

Do you have a production license for food contact materials (QS certification)?

Do we have complete procedures for raw material inspection (IQC), process control (IPQC), and finished product inspection (FQC)?

Production process capability:

Evaluate the technical proficiency of key processes such as stainless steel stretching, polishing, and welding.

Inspect the vacuum insulation technology equipment and the process control capabilities

Verify the maintenance records of production equipment and the effectiveness of process parameter control

Laboratory testing capabilities:

The factory laboratory should be capable of conducting material composition analysis, thermal insulation performance testing, and sealingity inspection.

Ensure that the detection equipment is regularly calibrated and in an operational state.

Check that the laboratory complies with the relevant national standards.

Supply Chain Management:

Verify the material certificates of the stainless steel raw material suppliers (304/316 food-grade)

Confirm that the plastic components meet the safety standards for food contact materials.

Check the storage conditions and material management standards

II. Finished Product Inspection: Sampling Inspection Standard Process for Thermal Cups

The inspection of thermal cups should follow the AQL sampling standard (usually LEVEL II) and conduct random sampling, covering multiple aspects such as appearance, material, performance, and safety.

1. Packaging and Label Inspection

Packaging materials: Check the strength of the outer box and the protective properties of the inner lining.

Product identification: Verify that the capacity, material, production date, and compliance standards, etc. are accurately and clearly indicated.

Instruction manual: Includes usage instructions, precautions, cleaning methods, etc.

2. Appearance quality inspection Surface treatment:

Check the uniformity of the shell's polishing, ensuring there are no scratches or depressions.

Coating or printing adhesion test (3M tape test)

Color consistency check

Structural Integrity:

Inspection of the one-piece molding process for the cup body

Inspection of the smoothness of the welding area

Assembly accuracy inspection of accessories

3. Material Safety Inspection - Key Test Items

Stainless steel material:

Use the stainless steel testing solution to verify the 304/316 material.

Check the smoothness of the inner liner surface and ensure there are no defects.

Plastic accessories:

Verification of food-grade PP/PC material

Odor test to ensure no irritating smell

Temperature resistance test to ensure no deformation

4. Performance Testing

Insulation Performance:

Place in boiling water and measure the temperature after 24 hours.

Standard: 24-hour insulation temperature ≥ 40℃ (95℃ → 40℃)

Sealing performance:

Inverted test to ensure no leakage

Shaking test, to check the sealing performance

Impact Resistance Test:

Drop from a height of 1 meter and check if it is damaged.

Simulate the collision situations that occur in daily use

5. Utilize functional testing

Smooth opening and closing: Check if the cup lid opens and closes smoothly

Drinking port test: Check whether the design of the drinking port is reasonable.

Portability: Check the strength of the carrying handle or the suspension ring

Cleaning convenience: Check if it is easy to clean without any blind spots.

III. Quality Grade Determination Criteria

1. Premium Grade

Material: 304/316 food-grade stainless steel

Thermal preservation: 24-hour preservation at ≥ 60℃

Process: Integrated molding, no welding

Sealing: No leakage after being inverted for 24 hours.

2. Qualified Product

Material: 304 food-grade stainless steel

Thermal preservation: 24-hour preservation at ≥ 40℃

Process: Excellent welding process

Sealing: No leakage after being inverted for 12 hours.

3. Defective Product

Material: Non-food grade stainless steel

Thermal preservation: 24-hour preservation at < 40℃

Process: Obvious defect

Sealing: There is a leakage problem.

IV. Classification of Common Defects

Serious Defects: Inadequate material quality, severe leakage, failure to meet insulation standards, potential safety hazards

Main defects: Obvious appearance flaws, average sealing performance, average insulation performance

Minor defects: Minor flaws in appearance, slight damage to packaging, minor errors in labeling

V. Inspection Rules and Criteria

Sampling plan: Based on the batch size, the sampling quantity is determined according to the AQL standard.

Defect determination:

If any serious defects are found, the entire batch can be judged as不合格 (unqualified).

The number of major defects exceeded the AQL acceptance limit, so it was determined to be non-compliant.

The performance parameters exceed the tolerance range, and are judged as unqualified.

Report Output: The detailed inspection report should include the sample size, test data, defect description, and test results.

Conclusion

The quality inspection of insulated cups requires professional knowledge and strict testing procedures. By evaluating the suppliers, it is ensured that the manufacturers have reliable production capabilities. Then, through the final product acceptance before shipment, a comprehensive performance verification of the products is conducted to form a complete quality assurance system. Purchasers and brand owners should particularly pay attention to material safety and insulation performance tests to ensure that the products meet the quality requirements and provide consumers with safe and reliable products.

分享这个商品

Inspection and testing standards for insulated cups Inspection and fac

As a daily drinking vessel, the quality of a thermos cup directly affects the safety and health protection during use.