Understand the first article inspection (FAI) in the electronics manufacturing field and the production part approval process (PPAP)

The cornerstone of quality in electronic manufacturing: First Article Inspection (FAI) and Production Part Approval Process (PPAP) analysis

In the field of electronic manufacturing, ensuring the excellent quality and full compliance of products is the core task. First article inspection (FAI) and production part approval process (PPAP) are two key quality verification processes that together form the quality assurance system from the birth of the product to stable mass production. Although both aim to ensure the integrity and reliability of components, their goals, focuses, and roles in the manufacturing life cycle are significantly different. A thorough understanding of the respective roles and collaborative relationship of FAI and PPAP is crucial for building a robust manufacturing quality defense line.

First Article Inspection (FAI): The initial verification checkpoint for design and process

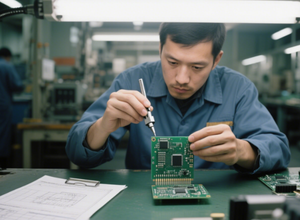

The first article inspection is a crucial verification and certification step for new products or products that have undergone significant revisions before the start of mass production. It is not merely a first inspection; rather, it involves a systematic and comprehensive verification of the first article or the first batch of products manufactured based on engineering drawings and technical specifications.

Design conformity inspection: One of the core tasks of FAI is to conduct rigorous design comparisons. Through precise dimension measurement, material composition analysis, and functional testing, it ensures that the first sample product is in complete accordance with the design intent in terms of physical characteristics, material properties, and performance. This can prevent deviations in design intent caused by misunderstandings or improper processes at the source.

Production process verification: FAI is also the initial test of the feasibility of the production process. It checks the calibration status of production equipment, the setting accuracy of tooling and fixtures, as well as the implementation of operation instructions, and verifies whether the established production process can stably and accurately replicate the design. This stage is equivalent to a small-scale production process inspection.

Risk forward-looking avoidance: By implementing thorough FAI before large-scale investment, potential defects existing in the design, materials, or manufacturing processes can be identified and corrected at an early stage. This forward-looking inspection effectively avoids the costly rework, delivery delays, and even product recalls that may occur after mass production, laying a solid quality foundation for subsequent production.

Production Approval Process (PPAP): Systematic certification for continuous and stable production

If FAI is to verify "whether a qualified first piece can be produced", then PPAP is to prove "whether a large number of qualified products can be continuously and stably produced". PPAP is a systematic approval process aimed at demonstrating through documented evidence that the supplier not only can produce samples that meet all requirements, but has also established a management system that can ensure consistent quality in long-term and batch production.

Submission of documented evidence: The PPAP requires suppliers to submit a complete set of detailed documents, including process flow diagrams, control plans, measurement system analysis (MSA) reports, etc. These documents collectively prove that their production process is under control and has the ability to continuously meet technical requirements, and are the key basis for the production system to obtain customer certification.

Production part sample inspection: The submitted samples must come from the official production line, be manufactured using the prescribed tooling, be produced by employees under the mass production schedule, and undergo comprehensive inspection and testing. This is not only the inspection of the product itself, but also a physical verification of the actual production capacity of the production line.

Customer approval and production license: The comprehensive review and final approval by the customer of the PPAP document package and samples signify the formal recognition of the entire production system and quality control capabilities. This approval serves as the necessary pass for initiating large-scale mass production, ensuring that all subsequent delivered products possess the expected quality consistency.

Core differences and collaborative value

FAI and PPAP play complementary and progressive roles in the quality control of electronic manufacturing:

Focus and Timing: FAI focuses on "the first piece", paying attention to the conformity of the single product to the design and the feasibility of the process. This occurs during the trial production or the early stage of mass production. PPAP, on the other hand, focuses on "the process system", paying attention to the proof of stability and consistency in mass production, which takes place before the approval for mass production.

Objectives and Outputs: The objective of FAI is to verify and correct. Its core output is a detailed first article inspection report, which is used to confirm that the design has been correctly implemented. The objective of PPAP is to prove and approve. Its core output is a complete submission package and the formal approval from the customer, which is used to confirm that the production system is ready.

Collaborative relationship: A successful FAI is an essential prerequisite for the successful completion of PPAP. The FAI verifies the accuracy of the design and process, providing initial confidence for the continuous production capacity demonstrated by PPAP. Together, they form a complete quality logical loop from "producing the first piece well" to "producing every piece stably".

Industry Practice: Integrating FAI and PPAP into a Modern Inspection System

In response to the increasingly complex quality requirements in electronic manufacturing, leading inspection and certification services are leveraging technological means to deeply integrate the core principles of FAI and PPAP, providing an integrated solution.

Enhanced implementation of FAI: By intervening at an early stage during the production process when a certain percentage (such as 5%-10%) has been completed, and conducting initial production inspections (IPC) using high-precision measuring equipment and professional inspection procedures, 100% compliance verification is carried out for the core indicators of the first batch of products, such as size, materials, and functions, to ensure the precise realization of the design intent.

Empowering PPAP data: Utilizing digital tools, systematic production data is collected during the inspection and factory verification processes. Through big data analysis of historical quality data (such as pass rates and defect type distribution), potential fluctuations and risk points in the production process can be accurately identified. This provides empirical support for optimizing control plans and strengthening process control, thereby helping enterprises establish and operate a continuous quality assurance system that meets PPAP requirements more efficiently.

分享这个商品

Understand the first article inspection (FAI) in the electronics manuf

he cornerstone of quality in electronic manufacturing: First Article Inspection (FAI) and Production Part Approval Process (PPAP) analysis