Infant and child products inspection

Baby diapers are disposable care products designed for infants and young children. They can effectively absorb urine, keep the baby's skin dry, and reduce the occurrence of diaper rash. Diapers are mainly composed of an absorbent core, a leak-proof layer, and a breathable outer layer. The absorbent core usually uses a polymer absorbent material (SAP) and fluff pulp, which can quickly absorb and lock urine, prevent back-seepage, and provide a long-term dry and comfortable experience. Modern diapers use soft and breathable surface materials to effectively reduce the feeling of stuffiness and protect the baby's delicate skin. At the same time, the ergonomic cutting design and elastic waist ensure that the diapers fit the baby's body, are not easy to leak, and are easy to put on and take off. In addition, many brands have also launched functions such as wetness display and antibacterial and anti-allergic to further enhance the user experience. Baby diapers have become an indispensable necessity in the process of modern family parenting with their convenience, hygiene, and safety, providing intimate care for the healthy growth of babies.

Product Categories

According to product structure, they are divided into baby diapers, baby diapers and baby diaper pads (nursing pads).

Baby diapers are divided into waist-type diapers and pants-type diapers according to the wearing method.

Baby diapers and baby diapers can be divided into different models according to product specifications, such as newborn (NB), small (S), medium (M), large (L), extra large (XL), and extra large (XXL).

Note: The product specifications of diapers for low birth weight infants can be determined by the user.

Technical requirements

The technical indicators of baby diapers, baby diapers and baby diaper pads (nursing pads) should comply with the requirements of Table 1.

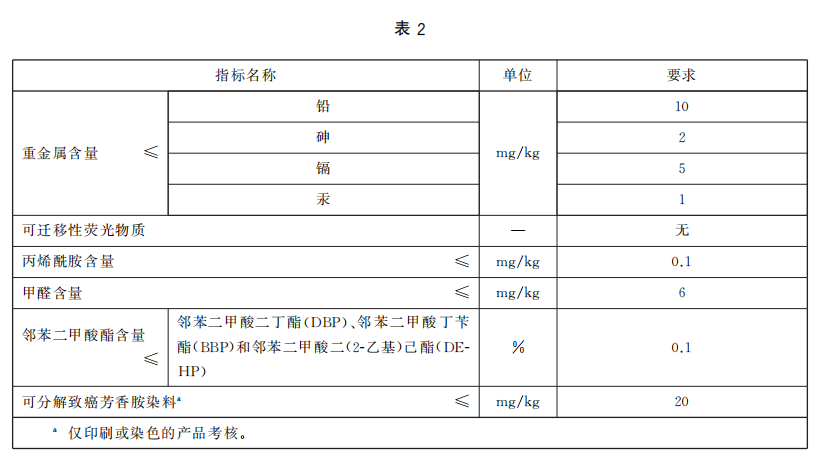

The safety indicators of baby diapers, baby diapers and baby diaper pads (nursing pads) should comply with the requirements of Table 2.

The hygiene indicators of baby diapers, baby diapers and baby diaper pads (nursing pads) shall comply with the provisions of GB15979.

The applicable weight and maximum waist circumference of baby diapers should comply with the requirements for baby diapers in GB/T33280-2016.

The appearance of baby diapers, baby diapers and baby diaper pads (nursing pads) should be clean and not faded, the leak-proof bottom film should be intact and not damaged, and the seal should be firm; the elastic bands should be evenly bonded, and the position of the fixings should meet the requirements of use.

Raw material requirements

Among the raw materials used in baby diapers, baby diapers and baby diaper pads (nursing pads), fluff pulp should comply with the provisions of GB/T21331, super absorbent resin should comply with the provisions of GB/T22875, dust-free paper should comply with the provisions of GB/T24292, and absorbent lining paper should comply with the provisions of QB/T4508.

Note: Enterprises are encouraged to use degradable materials to produce baby diapers, baby diapers and baby diaper pads (nursing pads). Baby diapers, baby diapers and baby diaper pads (nursing pads) made of degradable materials and their raw materials can be subjected to relevant tests in accordance with GB/T39951.

The management and control of chemicals and raw materials of baby diapers, baby diapers and baby diaper pads (nursing pads) manufacturers should comply with the relevant provisions of GB/T36420.

Test methods

Sample processing

When measuring the quality deviation, permeability, surface attachment and leakage prevention performance of the strips, the samples shall be treated for at least 4 hours under the temperature and humidity conditions specified in GB/T 10739 and the test shall be carried out under such conditions.

Quality deviation

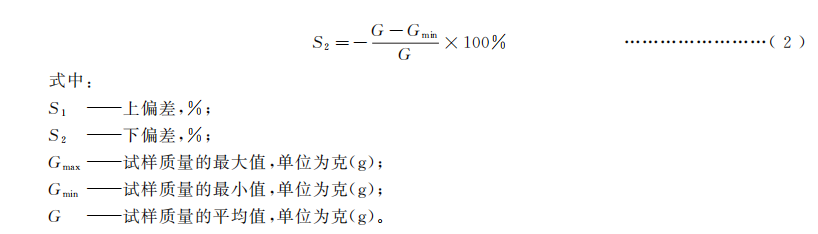

Use a balance with a sensitivity of 0.1 g to weigh the net weight of 6 samples of the same specification. The 6 samples should come from at least two minimum sales packages, and at least two samples should be taken from each package. Calculate the average weight of the 6 samples and calculate the mass deviation according to formula (1) and formula (2) with an accuracy of 1%.

Surface attachment

Warning—Copper sulfate is poisonous, use with caution.

Take two samples at random (from two smallest sales packages), cut the elastic band (pants-type diapers), fix the samples on a flat plate with a splint or tape, place them horizontally on the test bench, and use a spray pot to evenly spray 0.5% copper sulfate solution on the surface of the sample (slightly moisten the surface of the sample).

After 2 minutes, observe the surface layer facing the light to see if there are blue particles. If there are blue particles, continue to spray with 0.5% copper sulfate solution until the blue particles are saturated. After 5 minutes, observe their size by comparing with the standard impurity picture (C.2.3). If the area of blue particles on the surface layer of the sample is greater than 5.0 mm2, start counting. The arithmetic mean of the two samples is taken as the measurement result, and the result is rounded to an integer.

Anti-side leakage performance

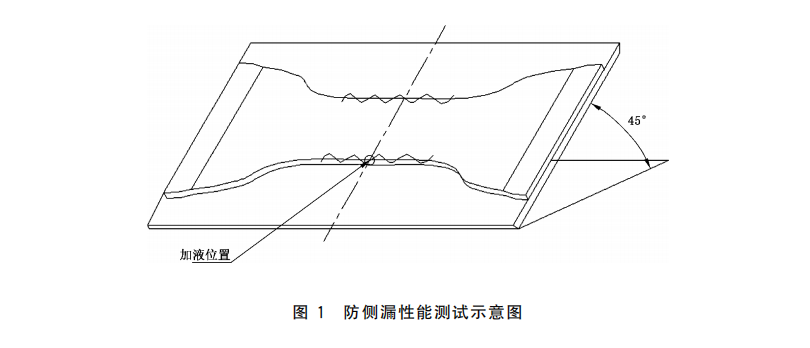

Take two samples (from two minimum sales packages) at random, cut the waist elastic band (pants-type diapers), and fix the samples on a rectangular flat plate with a splint or Velcro. The length direction of the sample should be parallel to the long side direction of the flat plate. Tilt the flat plate at 45° to the horizontal plane, gently open the leakproof edge below the middle of the diaper, and add 10mL of physiological saline to the seam in the middle of the leakproof edge at a speed of 5mL/s (do not pour it on the absorbent layer), and observe its side leakage. When adding liquid, the direction of adding liquid should be perpendicular to the surface of the diaper. After the test is completed, turn the flat plate over and continue to test the side leakage resistance of the leakproof edge on the other side. See Figure 1 for a schematic diagram of the side leakage resistance test.

If liquid flows out of any side of the leak-proof partition of the two samples, the sample is judged to have side leakage; if liquid flows out of the leak-proof partition of one of the two samples, the two samples are re-measured. After the re-measurement, if no liquid flows out of both samples, the sample is judged to have no side leakage, otherwise it is judged to have side leakage.

Delivery moisture

The moisture content of the delivered product shall be determined according to GB/T462. The sampling method is: take two packages of samples, take one sample from each package, cut the elastic band at the edge of the sample, and take 2g of the sample from the middle of the two samples. Cut the sample into blocks, mix them evenly, and divide them into two groups of samples for parallel testing. The absolute error between the two measured values should not exceed 1.0%. Take the arithmetic mean to express the measurement result, rounded to one decimal place.

Note: When placing the sample into the container, avoid the leak-proof bottom film from contacting the container wall to prevent adhesion after being exposed to high temperature.

Method for determination of permeability

The sample is placed on the sample holder and placed in a U-shaped sample base lined with absorbent paper. The standard test liquid adding module is placed in the absorption area on the sample surface. The sample is under a certain pressure. The liquid adding device injects a certain volume of physiological saline into the standard test liquid adding module. The automatic timing device records the time from the start of liquid addition to the complete absorption of physiological saline by the sample. Each sample is added with liquid twice, and the absorption speed of the sample is represented by the two absorption times. After the second liquid addition is completed, the standard test liquid adding module is taken out, a certain number of layers of absorbent paper are placed on the sample, and then the standard test pressurization module is placed. Pressurization is performed for a specified time under a certain pressure. The increase in the mass of the absorbent paper on the sample represents the back-infiltration amount of the sample, and the increase in the mass of the absorbent paper at the bottom of the sample represents the leakage amount of the sample.

Instruments, Equipment and Materials

Diaper Absorption Performance Tester

Instrument composition

The diaper absorption performance tester consists of a U-shaped sample base, a sample holder, a standard test module, a mobile pressurizing device, a liquid storage device and an automatic

It is composed of a dynamic liquid adding device, an automatic timing device, etc.

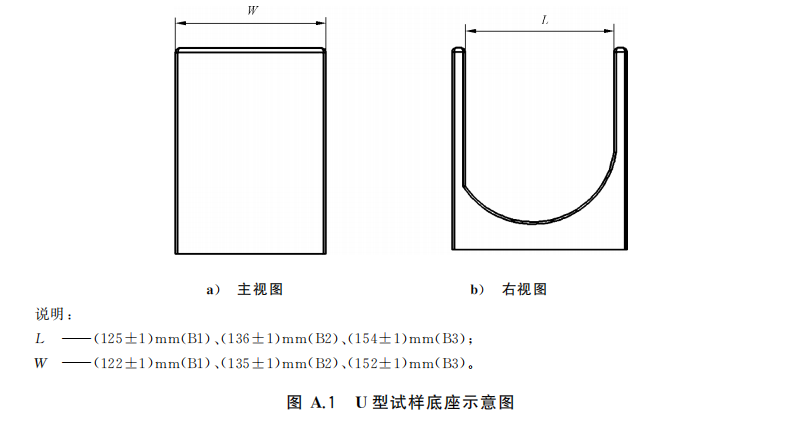

U-shaped specimen base

The U-shaped sample base is used to place absorbent paper, sample holder with sample and standard test module during the test.

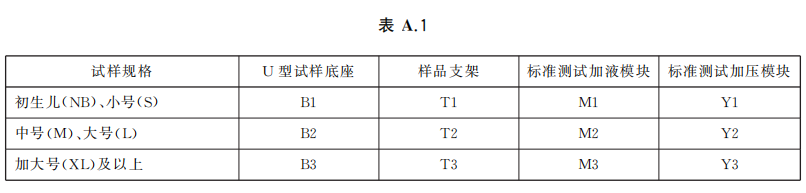

It is divided into three models: B1, B2 and B3, as shown in Figure A.1.

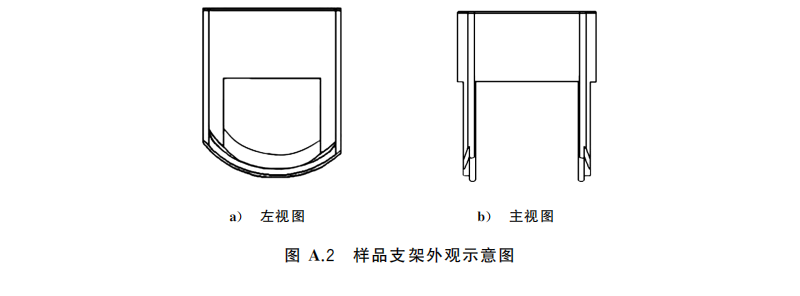

Sample holder

The sample holder is mainly used to fix the sample. It is divided into three types according to different specifications: T1, T2 and T3. The appearance is shown in Figure A.2

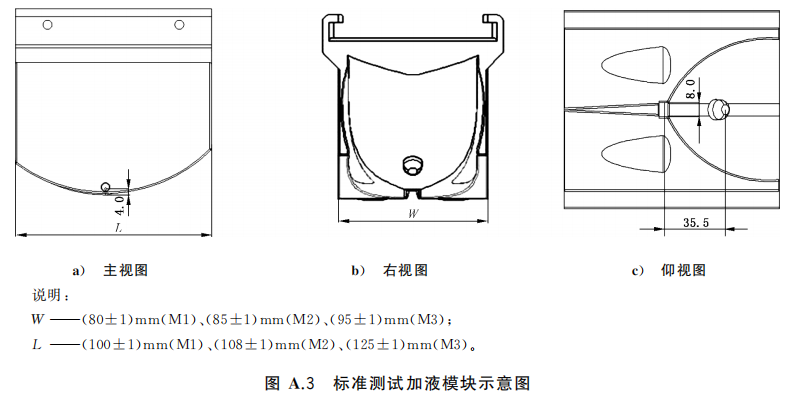

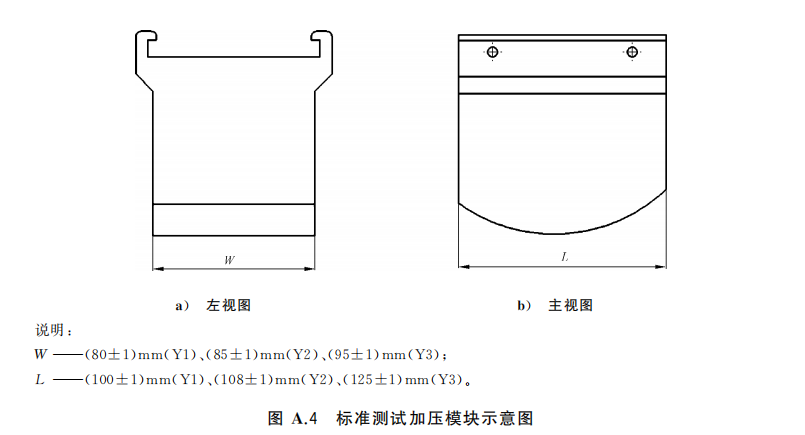

Standard test modules

The standard test module is divided into two types: standard test liquid adding module and standard test pressurizing module. The standard test liquid adding module is divided into three types: M1, M2, and M3 according to different specifications, and the standard test pressurizing module is divided into three types: Y1, Y2, and Y3 according to different specifications. The schematic diagram of the standard test liquid adding module is shown in Figure A.3, and the schematic diagram of the standard test pressurizing module is shown in Figure A.4. A timing unit is set at the bottom of the standard test liquid adding module, and the timing unit is (4.0±0.2) mm away from the bottom of the standard test liquid adding module. An arc-shaped concave absorption area is set at the front section of the module, and there is a liquid outlet at the lower part of the absorption area. The straight-line distance between the liquid outlet and the bottom of the arc of the standard test liquid adding module is (35.5±0.5) mm. There is a groove with a gradually changing width in the middle of the bottom of the test liquid adding module, and the maximum width of the groove is (8.0±0.2) mm. It is connected to the absorption area at the same time, and there are convex structures on both sides of the groove.

Mobile pressurizing device

The mobile pressurizing device can provide a constant pressure of (2.0±0.2) kPa and (4.0±0.2) kPa.

Liquid storage device and automatic liquid adding device

The liquid storage device is used to store the test solution. The liquid addition amount deviation of the automatic liquid adding device is ±2mL, and the liquid addition flow rate is (480±10)mL/min.

Automatic timing device

The automatic timing device consists of a timing unit, a timing control part, etc. It is used to automatically record the test time with a resolution of 0.01s.

water

GB/T6682, Level 3.

Normal saline

Weigh 9.00 g of sodium chloride (analytical grade) into a 1000 mL volumetric flask, add a small amount of food coloring, dissolve it, add water (A.2.2) to the scale and shake well.

Absorbent paper

The quantitative value is (145±5) g/m2, the water absorption is not less than 480%, and the water absorption is determined according to GB/T24218.6.

Electronic balance

The sensitivity is 0.01g.

Sample collection

Take 5 specimens from each sample, and the specimens should come from at least two sales packages. During the test, the test area of the specimen should not be touched by hand.

Determination of absorption rate and rewet amount

Test steps

Place the diaper absorption performance tester in a horizontal position, pour a sufficient amount of saline solution with food coloring into the liquid storage device, start the instrument, click the rinse button, and rinse twice. Calibrate the liquid volume of the automatic liquid adding device according to the instrument manual. The saline solution needs to be heated to (36±1)℃.

According to the specifications of the sample to be tested, select the corresponding model of U-shaped sample base, sample holder, standard test liquid adding module, and standard test pressure module as specified in Table A.1. Take a piece of sample and put it on the sample holder. The leakproof edge of the sample should be outside the sample holder. The surface of the sample should be as flat as possible and there should be no obvious dead folds. Place the U-shaped sample base on a horizontal table and put several layers of absorbent paper of known mass in the U-shaped test area. The length of the absorbent paper is 200mm and the width is preferably close to the width of the U-shaped sample base. When placed, the center of the absorbent paper coincides with the center of the U-shaped sample base. Gently place the sample holder with the sample in the U-shaped test area of the U-shaped sample base with the absorbent paper. When placed, the front end of the sample is on the left (L) side of the U-shaped sample base and the rear end is on the right (R) side of the U-shaped sample base. Then put the U-shaped sample base with the sample in the fixed position of the permeability tester.

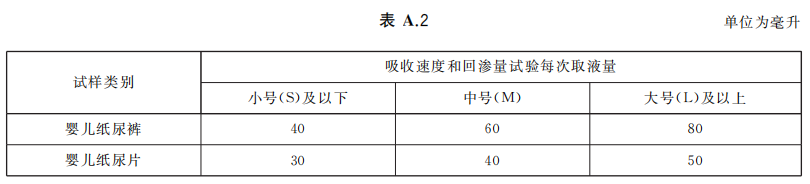

Enter the test interface of the diaper permeability tester, set the test pressure, click test, make the sample surface bear the pressure of (2.0±0.2) kPa, and at the same time, the automatic liquid adding device adds physiological saline to the standard test module of the corresponding model of the sample, and the liquid adding volume is selected according to the provisions of Table A.2. While adding liquid, the automatic timing unit automatically starts timing, and the absorption time is recorded until the liquid surface disappears at the lowest point of the absorption area. After pressurizing for 1 minute, take out the standard test liquid adding module (if the absorption speed is greater than 1 minute, take out the standard test liquid adding module after the absorption is completed), and complete the first absorption test.

After the first absorption test, wipe the bottom of the standard test module with a clean paper towel. Repeat the operation after 8 minutes from the first addition of liquid. The instrument's automatic timing device automatically records the second absorption time. The second absorption test is completed. The two absorption times are used as the absorption rate of the sample.

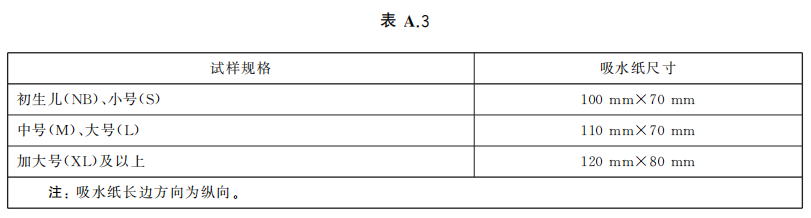

Counting from the first addition of liquid, at 15 minutes, quickly place 10 layers of absorbent paper of known mass on the surface of the sample (see Table A.3 for absorbent paper dimensions), with the center of the absorbent paper coinciding with the center of the arc surface of the standard test pressure module. At 16 minutes, start the permeability tester, press the corresponding standard test pressure module on the absorbent paper (the absorbent paper should be completely pressed by the pressure module and should not be exposed outside the pressure module), and apply a pressure of (4.0±0.2) kPa. After pressurizing for 1 minute, remove the standard test pressure module, take out the absorbent paper, and weigh the mass of the absorbent paper with a balance. The mass difference before and after the absorbent paper test represents the amount of back permeation of the sample.

After the test is completed, wipe the bottom of the standard test pressure module with a clean paper towel, remove the U-shaped sample base, remove the tested sample, and prepare for the next test.

Abnormal data of absorption rate test should be eliminated after eliminating the reasons of the sample. At least 5 valid data should be measured for each sample.

After completing all tests, clean the permeability tester and standard test module with distilled or deionized water.

In order to improve the test efficiency, a device for automatic and continuous testing of multiple samples can be used to complete the above test steps.

The results show

The absorption rate of the sample is expressed as the arithmetic mean of the test values of 5 samples, in seconds (s). The first absorption time and the second absorption time must be calculated, and the results must be rounded to the integer.

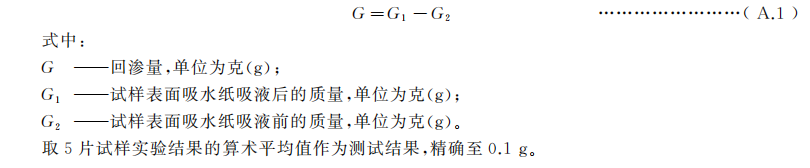

The amount of back seepage of the sample is expressed as the difference in mass before and after the absorbent paper test on the sample surface, and is calculated according to formula (A.1):

Leakage measurement

As mentioned above, after the back-seepage is measured, remove the sample and quickly weigh the mass of the absorbent paper placed at the bottom of the sample. The leakage of the sample is expressed as the difference in mass of the absorbent paper at the bottom of the sample before and after the test. The arithmetic mean of the five samples is taken as the final test result, accurate to 0.1g.

Determination of permeability of baby diaper pads (nursing pads)

Open the sample and lay it flat on a horizontal surface. Use a measuring cylinder to measure 80 mL of physiological saline, adjust the height of the measuring cylinder so that the outlet is 5 mm to 10 mm from the surface of the sample, and pour it into the center of the sample at a constant speed within 5 seconds. After 5 minutes, observe whether there is liquid seepage around the sample and whether there is liquid leakage at the bottom of the sample. Randomly select 3 samples, and none of the samples should have seepage or leakage.

Product sales labeling and packaging

The following information should be indicated on the product sales packaging:

a) Product name (including words such as baby diapers, baby diapers, baby diaper pads or baby nursing pads);

b) Part number;

c) Name of main raw materials;

d) Baby diapers and baby diapers should be marked with product specifications, and baby diaper pads should be marked with length and width;

e) Baby diapers and baby diapers should be marked with applicable weight;

f) Infant swimming diapers and infant training diapers should be labeled with their intended use (swimming diapers should contain the word "swimming" and training diapers should contain the word "swimming").

toilet training or similar terms);

g) Product conformity mark;

h) Other marking contents should comply with the requirements of relevant national laws, regulations and standards.

The sales packaging of the product should be able to ensure that the product is not contaminated, and the various identification information on the sales packaging should be clear and not easy to fade.

Share this product

Infant and child products inspection

Baby diapers are disposable care products designed for infants and young children. Many brands have also introduced functions such as wetness display and antibacterial and anti-allergic functions to further enhance the user experience. Baby diapers have become an indispensable necessity in the process of modern family parenting due to their convenience, hygiene and safety, providing intimate care for the healthy growth of babies.