Children's Woven Clothing Inspection

Children's woven clothing is children's clothing made of woven fabrics, suitable for daily life, study, going out and other occasions. Woven fabrics are made of warp and weft interwoven, with the characteristics of tight texture, crisp shape, wear resistance and washability. They are widely used in shirts, jackets, pants, dresses and other clothing. Children's woven clothing focuses on comfort and safety in design, and uses soft, breathable, non-irritating environmentally friendly fabrics to ensure that it does not harm the skin when worn close to the body. The cutting process is fine, in line with the characteristics of children's large amount of activities, easy to put on and take off without affecting daily activities. At the same time, the style design is diverse and the colors are rich, combined with cartoon elements, printed patterns, etc., which are deeply loved by children. Some products also have practical functions such as sun protection and water repellent, which enhances the practicality of outdoor wear. Children's woven clothing is both practical and beautiful, and is an indispensable and important part of children's daily wear.

Inspection requirements for children's woven clothing

Raw materials

The lining, stitching and other auxiliary materials used should be suitable for the fabric; buttons, decorative buckles, zippers and other accessories should have a smooth surface, no burrs, no defects, no imperceptible sharp points and sharp edges. Zippers should be well engaged and smooth.

Note: Touchable sharp points and sharp edges refer to sharp points and edges on the finished product that may cause harm to human skin.

Warp and weft direction

The yarn skewness of the collar, body, sleeves and trousers is no more than 3%, and the bottom edge of the front body is not curled up.

Matching

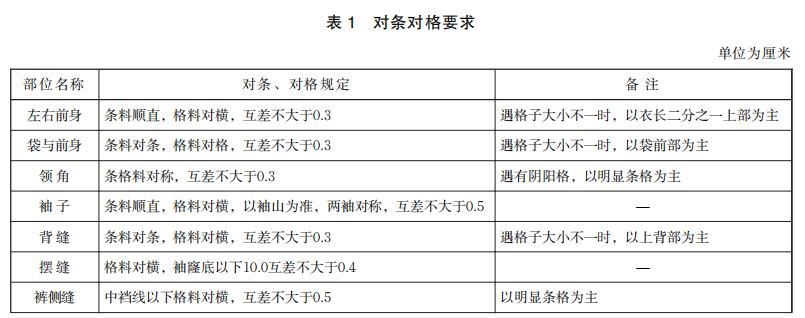

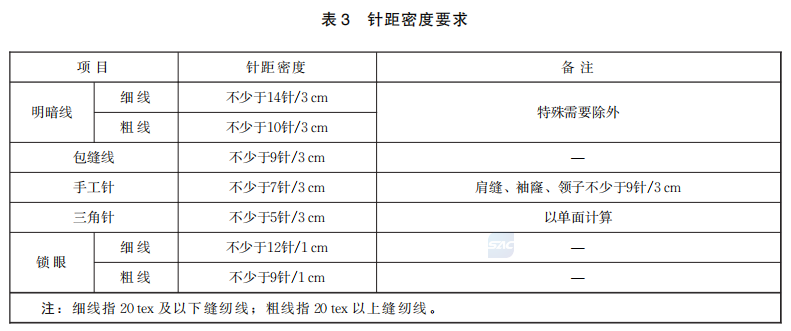

Fabrics with obvious stripes or grids with a width of 1.0 cm or more should comply with the requirements of Table 1, except for special designs.

The fabric has obvious stripes and grids of more than 0.5 cm and up to 1.0 cm (excluding 1.0 cm). The stripes of the bag and the front body are aligned, and the grids are aligned, with the difference not exceeding 0.2 cm.

The degree of skewness of the stripe pattern shall not exceed 3%.

The fabric is made of reverse and straight wool and yin-yang checkered, with the same straight direction all over the body.

Special pattern fabrics shall be based on the main image and shall be consistent throughout the body.

Chromatic Aberration

The color difference of the lining should not be less than 4﹘5. The color difference of the collar, lapel, front cape and the body should not be less than 4﹘5. The color difference of other surface parts should not be less than 4.

The color difference of the lining material shall not be less than 3﹘4 levels.

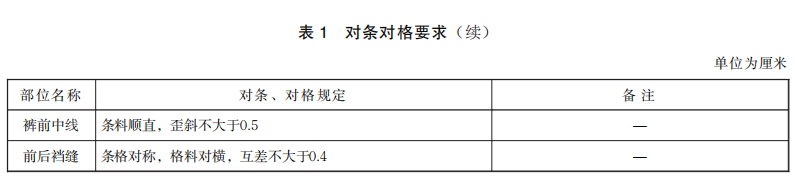

Appearance defects

The allowable degree of defects in each part of the finished product is specified in Table 2. The division of each part of the finished product is shown in Figure 1. Each part is allowed to have only one defect within the allowable degree. Defects not included in this document are specified in Table 2 according to their form. Special design or decoration is excluded.

Sewing

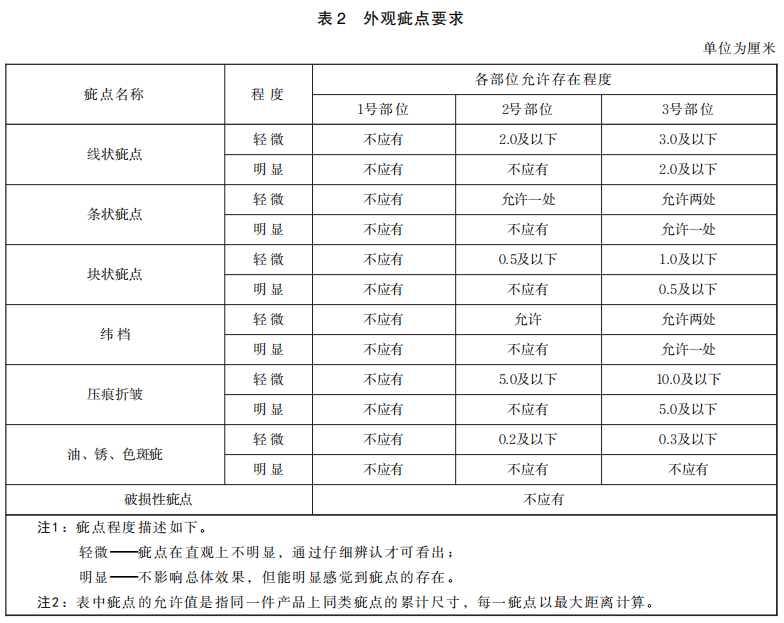

The needle pitch density should comply with the requirements of Table 3, except for special designs.

All parts should be sewn flat, with straight, neat and firm lines and even stitches. The upper and lower lines should be of appropriate tightness without skipped lines or broken lines. The starting and ending needles and the pocket opening should be sewn firmly with backstitching. The armholes, sleeve seams, hem seams, bottom edges, cuffs, lining of the hanging surface and other parts should be overlapped, and the back crotch seam of the trousers should be sewn with double thread or chain thread.

Exposed seams should be overlocked or heat-cut, and the seam allowance of each part should not be less than 0.8 cm, except for special parts such as pockets, collar stops, and placket stops. The stitching, rolling strips, and pressure strips should be flat and of uniform width. There should be no skipped stitches in the collar and placket. There should be no continuous skipped stitches or more than one single skipped stitch within 30 cm in other parts.

The collar is flat and not warped, the collar and lining are appropriately tight, the collar (collar shoulder seam comparison) is not skewed, and there should be no visible lines on the collar

wiring.

The sleeves are round and smooth, and the front and back sleeves are consistent. The length and position of the darts are consistent; the fine pleats (including tuck lines) are uniform, and the width of the pleats is consistent;

The length of the door and inner lapels is appropriate, and the mouth is closed without vomiting.

The bag cloth and padding should be folded or overlocked to prevent the edge yarn from falling off; the bag and bag cover should be square and round.

The elastic waistband of pants or skirt should be evenly tight and of consistent width.

The buttonhole should be positioned accurately and of appropriate size, and the buttonhole should be aligned with the buttonhole, neat and firm. The snap button should fit properly, without deformation or overtightening, and the zipper should be flat and straight. The button should not be nailed on a single layer of fabric (except for decorative deductions).

The side seams of pants (skirts) are straight, the distortion rate of pants is not more than 2%, the distortion rate of tube skirts is not more than 3%, and shorts above the knees are not tested.

The symmetrical parts are basically the same.

Decorations (embroidery, inlay, etc.) should be firm and smooth, with no missing embroidery and no matching colors in the prints.

The position of trademarks and durable labels should be straight and flat.

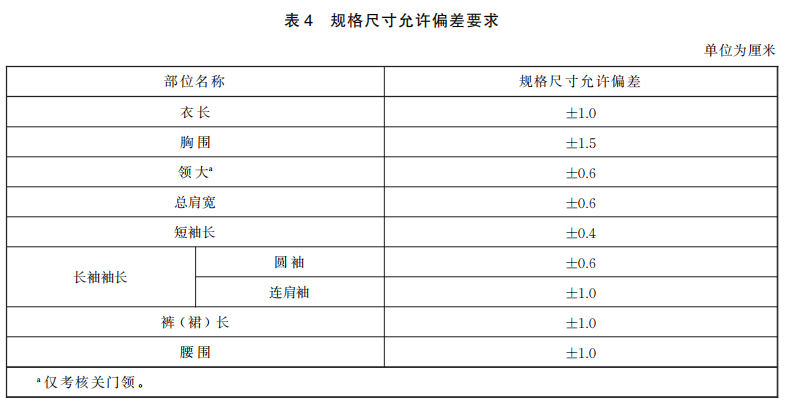

Specification size tolerance

The allowable deviations of the specifications and dimensions of the main parts of the finished product shall be as specified in Table 4.

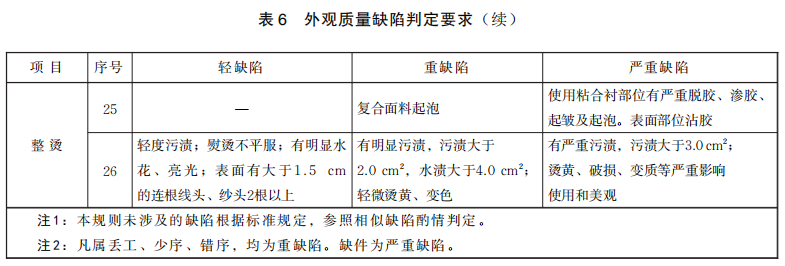

Ironing

All parts are ironed flat and neat, without yellowing, water stains or shine.

There should be no debonding, glue seepage, wrinkling or blistering in the adhesive interlining parts. There should be no glue on the surface of each part.

Physical and chemical properties

The physical and chemical properties of the finished product shall comply with the requirements of Table 5. The safety performance of clothing worn by children aged 3 to 14 shall also comply with the provisions of GB31701.

Appearance quality grades and defect classification rules

Appearance quality grade classification

The quality grade of finished products is based on the presence and severity of defects. The individual products in the sample are graded based on the number of defects and their

The severity of the disease is divided into grades, and the batch grade is divided according to the number of grades of individual products in the sampling sample.

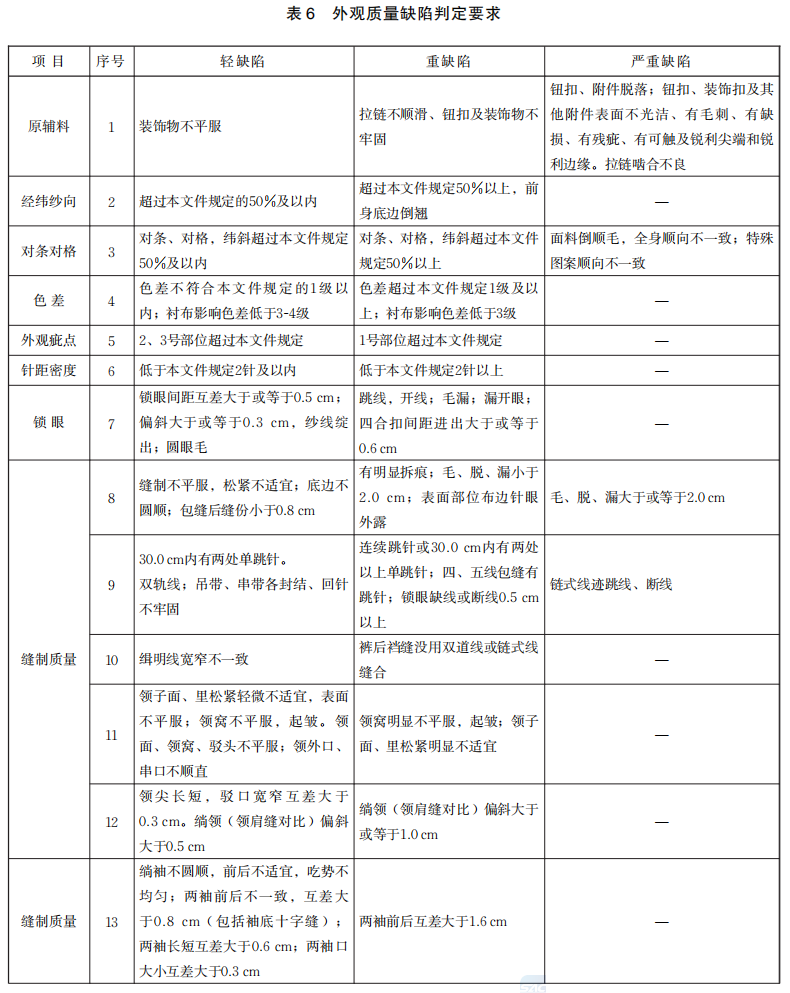

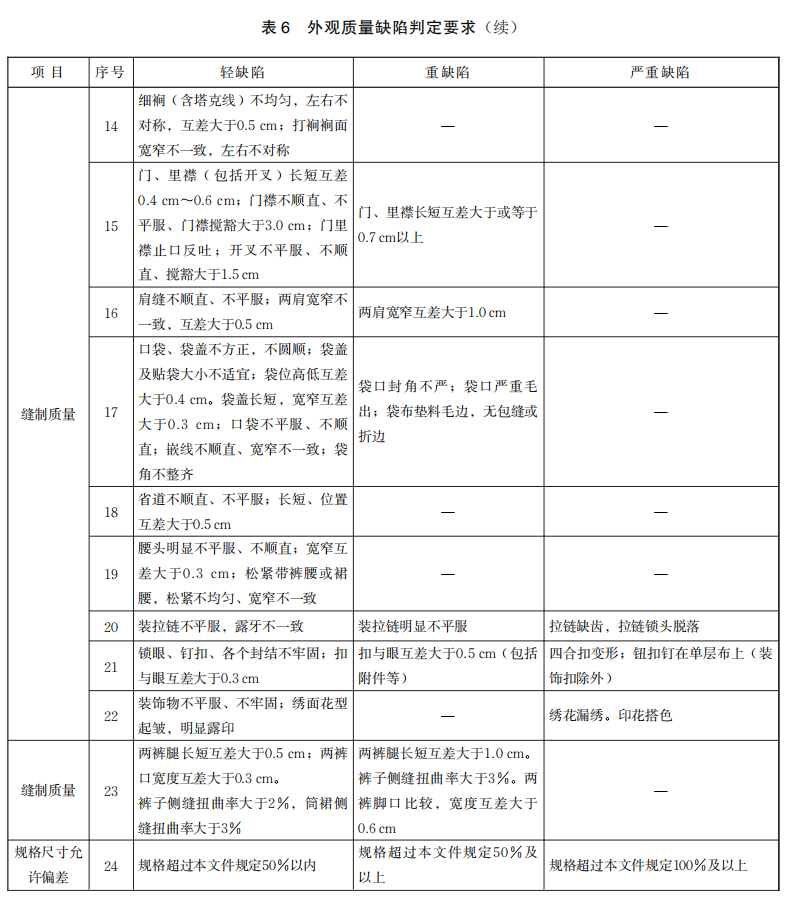

Appearance defect classification

A single product that does not meet the technical requirements set out in this document constitutes a defect.

Defects are divided into 3 categories according to the degree of non-compliance of the product with this document and the impact on the performance and appearance of the product.

a) Serious defects: defects that seriously reduce the performance of the product and seriously affect the appearance of the product.

b) Major defects: do not seriously reduce the performance of the product, do not seriously affect the appearance of the product, but are serious and do not comply with the requirements of the document

defect.

c) Minor defects: defects that do not comply with the provisions of this document but have little impact on the performance and appearance of the product.

Appearance quality defect judgment basis

The basis for judging appearance quality defects is shown in Table 6

Share this product

Children's Woven Clothing Inspection

Children's woven clothing focuses on comfort and safety in design. It uses soft, breathable, non-irritating and environmentally friendly fabrics to ensure that it does not harm the skin when worn next to the body. The tailoring process is fine, in line with the characteristics of children's large amount of activities, easy to put on and take off without affecting daily activities. At the same time, the styles and designs are diverse, the colors are rich, and they are combined with cartoon elements, printed patterns, etc., which are deeply loved by children.