Inspection requirements and methods for solid wood flooring

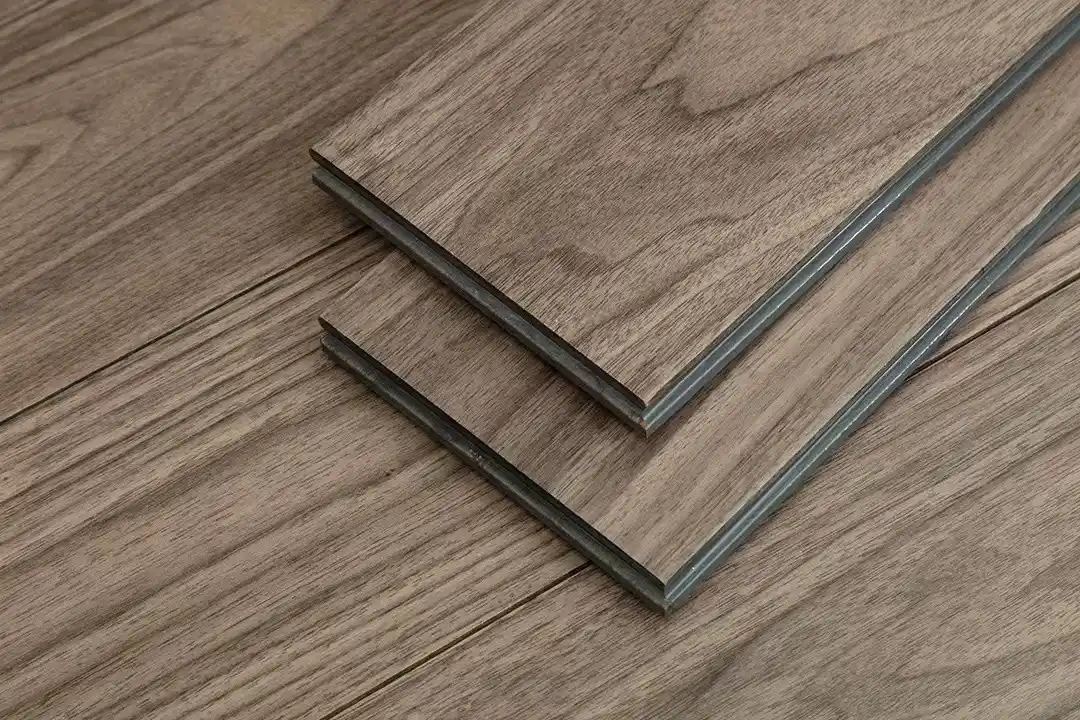

During renovations, ceramic tiles and solid wood flooring are common flooring material choices, with the trend toward solid wood flooring becoming increasingly pronounced in recent years. However, the wide variety of solid wood flooring on the market, with significant quality differences, makes proper inspection methods crucial. So, how should solid wood flooring be inspected? What are the specific inspection methods?

1. Classification of solid wood flooring <br>Solid wood flooring can be classified into the following categories according to different dimensions:

-

According to the surface morphology , it can be divided into flat solid wood floors with smooth surface and non-flat solid wood floors with special texture or concave and convex treatment.

-

According to whether the surface is painted or not : it is divided into painted solid wood floors with coated surface and unpainted solid wood floors that maintain the natural surface of the wood.

-

Differentiation by surface finishing type : Among the coated floors, they can be further divided into lacquered solid wood floors with a paint film on the surface and oiled solid wood floors treated with wood oil.

-

According to the processing technology , there are mainly ordinary solid wood floors made by conventional technology and antique solid wood floors that pursue special style and old-fashioned effects.

2. Measuring tools required for solid wood flooring inspection <br>Accurate inspection requires the use of the following tools:

-

Steel tape measure (measurement accuracy 1mm)

-

Steel ruler (measurement accuracy 1mm)

-

Vernier caliper (measurement accuracy 0.02mm)

-

Micrometer (measurement accuracy 0.01mm)

-

Feeler gauge (accuracy 0.01mm)

3. Dimensional Inspection <br>The dimensions of the flooring must comply with applicable standards. Each box is permitted to contain no more than three short boards, but these boards must be of the same thickness and their total length must match the nominal length of the flooring. Furthermore, dimensional, shape, and positional deviations must be within specified limits.

-

Length measurement : Use a steel tape measure or steel ruler to measure 20 mm from each of the two long sides of the floor, with the reading accurate to 1 mm.

-

Width measurement : Use a vernier caliper to measure 20 mm from each end of the floor and at the center point of the length of the floor, with the reading accurate to 0.02 mm.

-

Thickness measurement : Use a micrometer to measure at the four corners of the floor (20 mm from each long side and end side) and the midpoint of the long side (20 mm from the long side), with the reading accurate to 0.01 mm.

-

Tongue width measurement : Use a vernier caliper to measure the tongue width 20mm away from both ends of the floor, accurate to 0.02mm.

-

Warpage measurement :

-

Width direction : Place the floor with the concave side facing up on a horizontal surface, place a steel ruler close to its two long sides, and use a feeler gauge to measure the maximum chord height. Calculate the ratio of the maximum chord height to the actual width and express it as a percentage with an accuracy of 0.01%.

-

Length direction : Place the floor on a horizontal surface with its length direction sideways, place a steel ruler or wire rope close to its two ends, use a feeler gauge to measure the maximum chord height, and calculate the ratio of its maximum chord height to the actual measured length, expressed as a percentage, accurate to 0.01%.

-

4. Appearance Quality Inspection <br>The appearance quality of the floor must comply with the standard requirements. If there are special requirements, they will be implemented according to the customer's agreement. The inspection adopts the normal inspection double sampling plan with an acceptance quality limit (AQL) of 4.0.

-

The height of the inspection table should be around 700mm.

-

Lighting requires the use of three 40W fluorescent tubes with a spacing of approximately 400mm between the tubes. The length of the tubes should be parallel to the length of the floor. The height of the tubes should be approximately 2 meters from the inspection table, and interference from natural light should be avoided.

-

The inspectors must have normal vision and inspect the samples piece by piece at a viewing distance of 0.5m to 1.5m and a viewing angle of 30° to 90°.

-

Inspection is carried out in accordance with GB/T 4823-2013, and product grade is determined based on the quality requirements in the standard.

5. Physical and chemical performance test <br>The physical and chemical performance indicators of the floor, such as moisture content, paint film hardness, wear resistance, adhesion, etc., must all meet the requirements specified in the standards.

VI. Timber Name Conformity Verification <br>The timber name (Chinese name or trade name, with the Latin name) indicated on the product must be consistent with the actual timber. A random sample from the same batch of products will be collected for verification. If the conformity is confirmed, the product is qualified; otherwise, it is rejected. The names of the main timber species must be referenced in the standard catalog.

VII. Packaging, marking, transportation and storage inspection

-

Packaging : Products must be sealed and packaged according to category, specification, and grade upon shipment, ensuring they are protected from bumps, crushing, scratches, and contamination during the packaging process. Special packaging requirements may be agreed upon by both parties.

-

Labeling : Product packaging must be printed or affixed with clear, non-detachable Chinese labels. These should include: manufacturer name, address, product name, implementation standards, specifications, product grade, wood name (or trade name and Latin name), quantity, finish, and production date or batch number. Non-flat solid wood flooring must be specifically labeled on the outer packaging.

-

Transportation and storage : During transportation and storage, the products must be stacked flatly and protective measures must be taken to prevent them from being contaminated, damp, or rained on. At the same time, attention must be paid to preventing them from being fire-proof, waterproof, or insect-proof.

Share this product

Inspection requirements and methods for solid wood flooring

When renovating, many people choose between ceramic tiles and solid wood flooring, with more and more people opting for solid wood flooring. There are many types of solid wood flooring on the market, and the quality varies. How do you inspect solid wood flooring? What are the inspection methods for solid wood flooring?