The global standard for apparel quality control

The apparel industry is one of the most diverse and globally connected sectors, with manufacturers, designers and retailers operating across borders to meet consumer demand. However, this global presence also means that maintaining product consistency and quality across different markets can be a major challenge. From fashion-forward luxury brands to everyday apparel manufacturers, ensuring garments meet quality standards is critical to brand reputation and customer satisfaction.

In this article, we’ll explore the role of quality control in the apparel industry, the key methods used to maintain product consistency, and how different markets adhere to global standards.

What is quality control in the apparel industry?

Quality control (QC) in the apparel industry refers to the processes and techniques used to ensure that clothing meets specific quality standards before it reaches consumers. It involves checking raw materials such as fabrics and threads, as well as finished garments for defects or inconsistencies.

Quality control can be applied at all stages of garment production, from raw material inspection to final product evaluation. Its goal is to ensure that each product meets the required specifications in terms of durability, fit, appearance and functionality.

Why is quality control crucial in the apparel industry?

In a competitive global market, quality control is more than just a process; it is the key to success. The apparel industry caters to a wide range of consumer demands, from fast fashion to high-end custom designs, so maintaining high quality is critical for the following reasons: First, inconsistent or poor quality apparel can lead to negative reviews, product returns, and damaged brand reputation. Quality control ensures that customers receive products that match their expectations. Brand reputation is built on product quality, so consistently delivering high-quality apparel strengthens customer loyalty and trust.

Additionally, discovering defects early in the production process can save manufacturers time and money. Defective products discovered in the final stages of production may need to be discarded or reworked, both of which increase costs. Another factor to consider is market compliance. Different markets have different regulatory requirements for product quality. Adhering to the quality control standards of different markets ensures compliance with these regulations and reduces the risk of facing fines or recalls.

Key Quality Control Methods in the Apparel Industry

Maintaining quality throughout the garment production process requires applying methods that ensure that each garment is of consistent quality and meets necessary requirements before it reaches the consumer. At a minimum, you should consider the following quality control methods:

- Raw material inspection : Before production begins, raw materials such as fabrics, buttons, zippers and threads are inspected for quality. The fabrics are checked for color fastness, strength and shrinkage potential. Materials that do not meet the requirements will be rejected.

- Mid-production inspection : This method involves inspecting garments at various stages of production. Inspectors check for sewing defects, sizing, and pattern alignment. Mid-production inspections resolve any issues before the garment is finished, saving time and reducing waste.

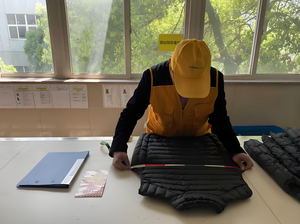

- Final Inspection : Once the garment is finished, a final inspection is performed to assess the overall quality of the finished product. Inspectors check for defects such as loose threads, incorrect sizing, or misaligned seams. Only garments that pass the final inspection are packaged for sale.

- Random Sampling : In mass production, it is not feasible to inspect every garment. Instead, a percentage of garments are selected for inspection using random sampling methods. If defects are found in the sample, further inspection or corrective action may be taken.

The role of clothing quality management system in the clothing industry

In addition to individual quality control techniques, many manufacturers implement a broader garment quality management system (QMS) to ensure that quality is maintained throughout the production process. A QMS specifies standard operating procedures, defines quality standards, and outlines the responsibilities of each team member involved in garment production.

A strong quality management system helps ensure consistency between production batches and minimizes the risk of human error. It also provides a framework for continuous improvement, enabling manufacturers to identify and resolve any recurring issues in the production process.

The main challenges and solutions for garment quality control

One of the core challenges in implementing quality control in the apparel industry is the diversity and complexity of quality standards in the global market. There are significant differences in the safety, environmental protection, performance and labeling requirements of clothing in different countries and regions, as shown in the following:

The EU market is known for its stringent chemical safety standards. For example, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) prohibits the use of more than 1,000 hazardous substances and sets precise limit values for color fastness, formaldehyde content, nickel content, etc. Labels must comply with CE certification requirements and include information such as material composition, washing instructions, size standards (EN standards), and eco-textile certification (such as GOTS) has gradually become a market entry threshold.

The US market focuses on product safety and compliance. The US Consumer Product Safety Commission (CPSC) stipulates that clothing must pass the ASTM flame retardant test (such as children's clothing must comply with 16 CFR Part 1615/1616), and infant clothing is prohibited from using chemicals such as phthalates; labels must clearly indicate the origin, fiber composition (FTC standards) and care instructions. California Proposition 65 (CA Prop 65) also sets additional limits on substances such as lead and formaldehyde.

The Chinese market implements mandatory national standards (GB), such as GB 18401-2010 "National Basic Safety Technical Specifications for Textile Products", which sets requirements for pH value, odor, degradable carcinogenic aromatic amine dyes, etc. Infant and toddler clothing must meet Class A standards (formaldehyde ≤ 20 mg/kg); functional clothing (such as sportswear, down jackets) must pass performance tests such as GB/T 2662-2017, and the label must be marked with the implementation standard number and safety technology category.

The Japanese market is famous for its sophisticated requirements. The JIS standard has detailed provisions on clothing sewing strength (such as seam slippage), washing shrinkage (JIS L 1096), and color fastness (JIS L 0844). Infant and toddler clothing must pass the safety certification of the Japan Textile Inspection Association (JTIA), labels must be marked in both Japanese and English, and the size system (such as M/L/LL) is different from international standards.

The Middle East market focuses on religious and climate adaptability standards. For example, traditional clothing such as abaya must pass GCC certification, which requires that the fabric must be non-transparent and the dye must not contain ingredients that are easy to fall off. For high temperature environments, clothing breathability and sun protection factor (UPF) become key indicators, and materials that do not conform to religious customs, such as pig leather, are prohibited.

In recent years, Southeast Asian markets (such as Vietnam and Thailand) have strengthened ecological standards, requiring clothing production to comply with the ASEAN Eco-Label (AEL) and restricting the use of azo dyes, chlorine-containing bleaches, etc.; clothing exported to the region must comply with local environmental regulations, such as Vietnam's TCVN 7433-2013, which limits the concentration of chemical substances in wastewater discharge.

The response method needs to start with systematic management:

- Establish a multi-market compliance management system : formulate a quality standard matrix covering major global markets, clarify the differentiated requirements of each market in terms of chemical safety, physical properties, labeling and identification, and form a dynamically updateable compliance database.

- Implement tiered quality standard documents : embed market-specific requirements into internal corporate standards, such as the “Green Supply Chain Checklist” for the EU market and the “Children’s Clothing Safety Checklist” for the US market, to ensure that all production links are traceable.

- Strengthen collaborative supply chain management and control : Sign cross-market compliance agreements with raw material suppliers, require them to provide test reports that comply with the target market (such as the EU's Oeko-Tex Standard 100 and the US's CPSC certification), and conduct regular supplier audits.

- Deepen localized compliance cooperation : Establish long-term cooperation with third-party certification bodies in the target market and conduct pre-compliance assessments during the product design phase to avoid subsequent rectification costs.

- Build a dynamic standards tracking mechanism : Assign dedicated personnel to track regulatory updates in various markets (such as the EU's annually updated REACH appendix and the US CPSC's recall cases), and adjust quality control processes in a timely manner to ensure the timeliness of standard implementation.

- Carry out global talent training : regularly organize the quality control team to learn about the differences in regulations in different markets, such as "Analysis of Sewing Process Standards" for the Japanese market and "Religious Culture and Material Taboos" training for the Middle East market, to enhance the compliance awareness of front-line personnel.

By putting market differentiation requirements in the quality control system in advance, companies can systematically respond to the challenges of global standard differences. While ensuring product consistency, they can achieve an efficient operating model of "one set of production processes to meet multiple market access" and lay a quality foundation for brand globalization.

Quality control is critical in the apparel industry to maintain product consistency and meet consumer expectations in different markets. From inspecting raw materials to implementing a strong quality management system, you must take steps to ensure your products meet global standards. While challenges such as supplier differences and human error can affect quality, implementing best practices such as third-party inspections, third-party audits, and continuous improvement processes will help you maintain high quality standards during production.

By prioritizing quality control, apparel manufacturers can build a reputation for reliability and excellence, ensuring long-term success in a competitive global marketplace.

Share this product

The global standard for apparel quality control

The apparel industry is one of the most diverse and globally connected, with manufacturers, designers and retailers operating across borders to meet consumer demand. However, this global presence also means that maintaining product consistency and quality across different markets can be a major challenge.