Leather sandals inspection requirements and methods

Leather sandals are a type of footwear commonly used in summer, made of natural leather or high-quality artificial leather as the main material. They have the characteristics of good breathability, elegant texture, and comfortable wearing. According to different usage scenarios and design styles, leather sandals are divided into men's, women's and children's styles, and are widely used in daily wear, business leisure and outdoor activities. The uppers are mostly made of soft materials such as cowhide and sheepskin, combined with ergonomic design to provide good fit and support. The soles are mostly made of non-slip and wear-resistant rubber or polyurethane, which makes walking more stable. High-quality leather sandals pay attention to details in the production process, such as uniform stitching, smooth edges, simple and generous appearance, and both practical and beautiful. Compared with ordinary sandals, leather sandals have more texture and grade. They are an ideal choice for keeping cool in summer without losing taste. They are deeply favored by people who pay attention to wearing quality and comfort.

Product Categories

Classification by user

According to the object of wearing, it can be divided into the following two categories:

a) Men's leather sandals (boots);

b) Women's leather sandals (boots).

By style

The styles are divided into the following six categories:

a) Strappy leather sandals (boots);

b) Full-length leather sandals (boots);

c) Hollow leather sandals (boots);

d) Leather sandals (boots) with hollow front;

e) Leather sandals (boots) with hollow back;

f) Other styles of leather sandals (boots).

Classification by upper material

According to the upper material, it is divided into the following four categories:

a) Natural leather (top leather, split leather) upper leather sandals (boots);

b) Artificial leather or synthetic leather upper leather sandals (boots);

c) Leather sandals (boots) with textile uppers;

d) Leather sandals (boots) with uppers made of a variety of materials.

Classification by manufacturing process

According to the manufacturing process, it is divided into the following seven categories:

a) Adhesive leather sandals (boots);

b) Sewing leather sandals (boots);

c) Molded leather sandals (boots);

d) Vulcanized leather sandals (boots);

e) Injection leather sandals (boots);

f) Infused leather sandals (boots);

g) Other craft leather sandals (boots).

Require

Sensory quality

The sensory quality requirements are shown in Table 1, among which items 1 to 5 and the serious defects in Note 1 are the main items, and items 6 to 10 are the secondary items.

Physical and mechanical properties

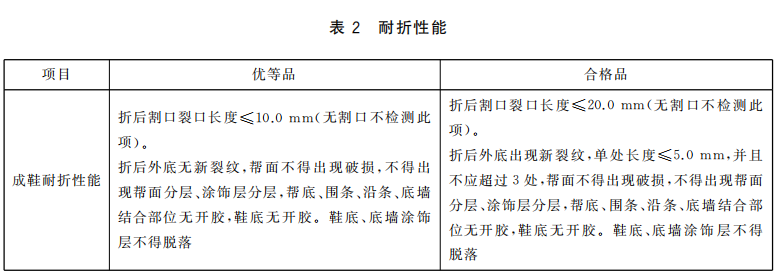

Folding resistance

The technical indicators of folding resistance are shown in Table 2.

If any of the following conditions occurs, the folding resistance will not be tested:

If any of the following conditions occurs, the folding resistance will not be tested:

a) Shoe size is less than 230;

b) The rigidity of the whole shoe is tested according to the provisions of 8.4.1 of GB/T20991-2007, and the folding angle under the force of 30N is less than 45°;

c) Heel height greater than 70mm;

d) The thickness of the flexion part of the sole is greater than 25mm.

Note: The thickness of the flexure area includes the thickness of the inner pad and does not include the thickness of the bottom wall part above the inner pad.

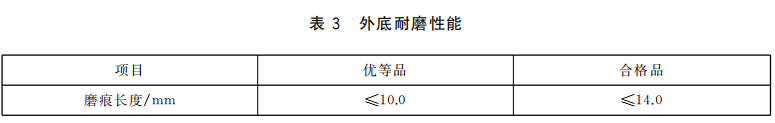

Outsole wear resistance

The wear resistance of the outsole shall comply with the requirements of Table 3.

No under-sulfurization or outsole wear is allowed.

The wear resistance of natural leather outsoles is not tested.

Upper and bottom peel strength

The peeling strength of the upper and sole of leather sandals that are sewn or glued or manufactured using special techniques (including riveting, etc.) is not tested. The peeling strength of leather sandals manufactured using other techniques is tested.

When one of the following situations occurs, the peel strength is not measured and the pull-out strength of the auxiliary tape is measured instead.

a) Leather sandals with hollow front;

b) The thickness of the sole test part exceeds 25mm;

c) The width of the outer bottom at 1 mm from the front end point is less than 25 mm;

d) The outer sole hardness is less than 50 Shore A;

e) For the soles without edges, the peeling test cannot be performed due to the slipping of the knife;

f) Other situations that are not suitable for testing peel strength.

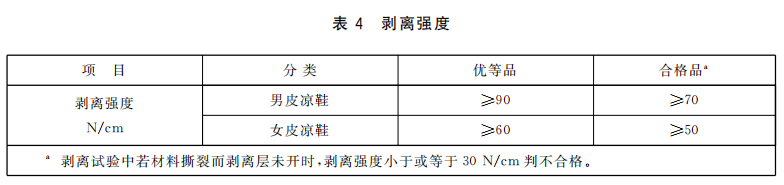

The technical indicators of upper and bottom peeling strength are shown in Table 4.

When one of the following conditions occurs, the peel strength shall not be less than 40N/cm:

a) The upper surface is made of sheepskin leather or artificial materials;

b) The thickness of the front end of the outsole is less than 3mm;

c) The width of the outsole at 20 mm from the front end of the outsole is less than 40 mm.

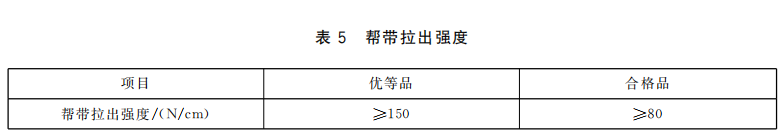

Pull-out strength of belt

The pull-out strength of the upper strap shall be measured when any of the following conditions occur, otherwise it shall not be measured. This item shall not be measured for leather sandals that are sewn or glued or made by special techniques (including riveting, etc.).

a) Leather sandals with hollow front;

b) The thickness of the sole test part exceeds 25mm;

c) The width of the outer bottom at 1 mm from the front end point is less than 25 mm;

d) The outer sole hardness is less than 50 Shore A;

e) For the soles without edges, the peeling test cannot be performed due to the slipping of the knife;

f) Other situations that are not suitable for testing peel strength.

The pull-out strength of the auxiliary belt shall comply with the requirements of Table 5.

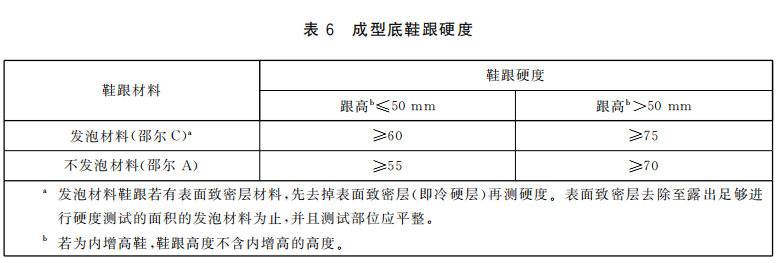

Molded heel hardness

The hardness of the heel is measured for molded soles with a heel height of more than 25 mm and without an inner heel or other reinforcing materials; the rest are exempt from testing.

The hardness index of the molded sole heel is shown in Table 6.

Outsole and midsole bonding strength

The bonding strength between the outsole and the outer midsole is greater than or equal to 20N/cm, and when the microporous sole is torn but the rubber layer does not open, it is greater than or equal to 15N/cm.

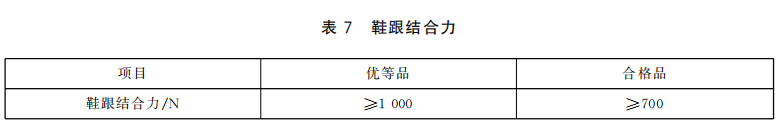

Heel bonding strength

Leather sandals with assembled heels and heel height greater than 30mm must be tested for heel bonding strength, while others are exempt from testing.

The heel bonding force should meet the requirements of Table 7.

The heel bonding strength of assembled heels that cannot be clamped by the back is not tested.

Intrigue

Women's shoes with a heel height of more than 20.0mm and a heel opening of more than 8.0mm, and men's shoes with a heel height of more than 25.0mm and a heel opening of more than 10.0mm should be installed with shanks or other rigid support materials.

The longitudinal stiffness, hardness, lower length limit and bending performance of the steel shank shall comply with the requirements of GB/T28011.

The shank of the injection molded midsole leather sandals is not tested. The longitudinal stiffness of the midsole should meet the requirements of QB/T4862-2015.

The shanks of wedge-heeled shoes are not tested. The shanks of shoes with wooden or hard plastic molded soles (hardness ≥ 80 Shore A) are not tested.

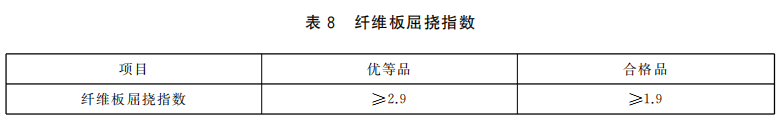

Fiberboard Flex Index

The fiberboard flex index index is shown in Table 8.

Colour fastness to rubbing of lining and inner padding

The staining of general materials is greater than or equal to 2-3 (gray sample card), and the staining of suede is greater than or equal to 2 (gray sample card). Note: If there is no lining, the contact surface between the upper and the foot is tested as the lining.

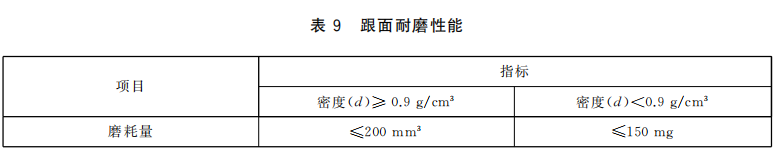

Heel wear resistance

The assembled heel surface shall comply with the requirements of Table 9.

Restricted substances

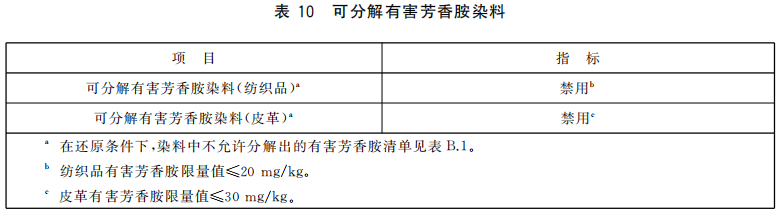

Can decompose harmful aromatic amine dyes

The content indicators of degradable harmful aromatic amine dyes are shown in Table 10.

Test methods

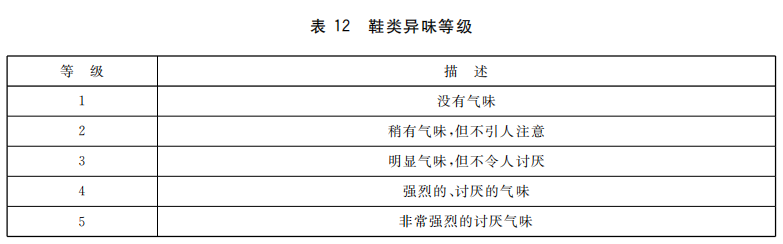

Odor

Test equipment: Dryer, 300mm diameter. For samples with a back height greater than or equal to 250mm, a dryer with a diameter of 400mm should be selected.

Test environment: The test should be carried out in a clean environment with no abnormal odor and where gas can be freely dissipated.

Judges: At least three. Judges should be professionals who have undergone certain training and assessments and should not have olfactory defects. Smoking enthusiasts, people who use heavy perfumes and cosmetics, and people who are drunk are not suitable as judges.

Sample quantity: 1 pair.

The test steps are as follows:

a) Clean the dryer and make it dry and odorless.

b) Place each shoe in a desiccator, cover it with a lid, and leave it at room temperature for 24 hours.

c) When judging the odor, move the lid 20mm away from the opening, and the tester should put his nostrils close to the test container (about 15cm away), then fan it with his hands and slowly sniff the gas in the dryer for no more than 5s.

d) Repeat step c) for the other shoe. The interval between the two tests is 2 minutes.

Test result determination: The odor level of each shoe is determined according to the provisions of Table 12. The result agreed upon by more than half of the judges is the evaluation level of the shoe, and the maximum level is taken as the test result of the group of samples.

Folding resistance

Tested according to GB/T3903.1-2008. Pre-cut 5mm, continuous flexion 40,000 times. Natural leather outsole is tested for 40,000 times without cut.

Outsole wear resistance

Tested according to GB/T3903.2-2008. Apply 4.9N pressure and wear continuously for 20min.

The outsole is the contact point between two (or more) materials and the ground.

If no wear marks are found on the specimen after the test, it is judged to meet the standard requirements.

Upper and bottom peel strength

Tested according to GB/T3903.3-2011. Blade width (10±0.2) mm.

Pull-out strength of belt

Sample preparation: For a pair of samples, cut the upper strap and the sole horizontally into 10mm wide test strips, and take one sample from the inside and outside of each shoe. If the width of the upper strap is less than 10mm, the sole remains in its original state, and the upper strap is cut in the middle, and one side of the upper strap and the sole are clamped for testing, and each shoe is tested once on the inside and outside.

Test equipment: Tensile testing machine, accuracy level 2, range 500N.

Clamp moving speed: (25±5)mm/min.

Ambient temperature: (23±2)℃.

The upper and lower clamps of the testing machine clamp the sole of the shoe (the upper and sole bonding layer must not be clamped) and the upper strap respectively.

The maximum force when the upper and sole are pulled apart is the pull-out force.

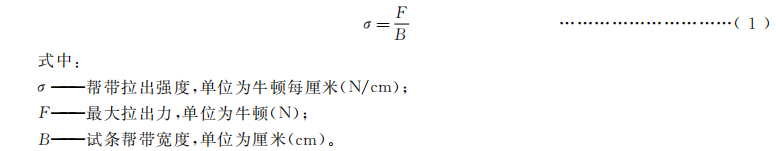

The pull-out strength of the auxiliary belt is calculated according to formula (1):

For each shoe, the lower value of the pull-out strength of the upper straps of the two specimens is taken as the test result, and each test result is expressed separately.

Molded heel hardness

Non-foaming materials are tested using a Shore A hardness tester in accordance with GB/T3903.4-2008 standard.

The foaming material is tested using a Shore C hardness tester in accordance with GB/T3903.4-2008 standard.

Outsole and midsole bonding strength

According to GB/T21396-2008, the sample quantity is 1 pair, 1 specimen is cut from each sole, and the test result is the lower value of the test results of 2 shoes.

If the sample sole is a hard waterproof platform or a molded bottom with soft material, cut a 50mm×15mm sample from the outer soft material of the waterproof platform, and use a sharp cutting knife to cut the outer soft material without cutting the hard material, and then inspect according to GB/T21396-2008.

Heel bonding

Inspected according to GB/T11413-2015.

Intrigue

The longitudinal stiffness, hardness, length lower limit and bending performance of the steel shank shall be tested according to the test methods specified in GB/T28011. If the shank is injected into the sole and cannot be removed, the same type of shank should be taken from the warehouse for testing.

Fiberboard Flex Index

According to QB/T1472-2013, samples are taken from the factory warehouse with the same materials for inspection.

Colour fastness to rubbing of lining and inner padding

According to method A in QB/T2882-2007, the test is carried out by rubbing with sweat 50 times. When it is impossible to take samples of the lining and inner pad, the same materials are taken from the factory warehouse for inspection.

Share this product

Leather sandals inspection requirements and methods

Leather sandals are a type of summer footwear made of natural leather or high-quality artificial leather. They are breathable, elegant, and comfortable to wear. Depending on the usage scenario and design style, leather sandals are divided into men's, women's, and children's styles, and are widely used in daily wear, business leisure, and outdoor activities.