Textile Inspection

Garment interlining is an auxiliary material used for supporting and shaping the internal structure of clothing. It is widely used in various types of clothing such as suits, shirts, coats, and skirts. Its main function is to enhance the stiffness, stability, and durability of clothing, making the finished garment more three-dimensional and with a good wearing effect. Common interlinings are divided into bonded interlinings and non-bonded interlinings according to their uses, and divided into cotton interlinings, chemical fiber interlinings, and wool interlinings according to their materials. Bonded interlinings are bonded to fabrics through high-temperature pressing, which is convenient for construction and suitable for industrial mass production; non-bonded interlinings are mostly used for high-end customization and have better comfort and breathability. Interlinings play a role in shaping, supporting, and protecting fabrics in collars, plackets, shoulders, cuffs, and other parts. High-quality interlinings should have good bonding strength, softness, and washability, and should not affect the appearance and feel of finished garments. As a key auxiliary material in clothing production, interlinings play an important role in improving the quality of finished garments and wearing experience.

Garment interlining inspection equipment and tools

Fabric inspection machine: The table top is at an angle of 45° to the vertical line. Three to four 40 W ultraviolet light tubes and three to four 40 W blue fluorescent light tubes are installed in the upper and lower lampshades respectively. The fabric inspection machine has a speed of 5m/min~30m/min and is equipped with a length measuring device.

Fabric inspection table: The width is larger than the fabric surface, the length is longer than 1m, the table surface is flat and smooth, and a 40W fluorescent tube or ultraviolet tube is installed 1.0m~1.2m above the table surface, or natural light is exposed to the north.

Ruler or tape measure: in accordance with GB/T19022, larger than the measurement size, with a minimum graduation value of 1mm.

Color card: gray sample card for evaluating color change in accordance with GB/T250.

Inspection conditions and operation requirements for garment interlinings

Inspection conditions

Lighting inspection is adopted. For woven interlining, knitted interlining and non-woven interlining containing fluorescent agent, three to four 40W ultraviolet light tubes are adopted; for dark outerwear interlining, two 40W cyan fluorescent tubes are adopted, and the illumination is not less than 400lx; for the rest, three to four 40W cyan fluorescent tubes are adopted, and the illumination is not less than 750lx.

The distance between the inspector's eyes and the cloth surface is 55.0cm~60.0cm.

The maximum speed of the fabric inspection machine is 30m/min.

Operation requirements

Use fabric inspection machine or platform for inspection.

When inspecting defects on clothing linings, the front side of the lining shall be used as the standard (the side with marks such as cover products shall be the back side).

During inspection, the inspector should look straight at or obliquely at the fabric surface.

For each defect, use a measuring tool (5.3) to measure the length of the defect on the fabric.

When there is a conflict between the inspection of the fabric inspection machine and the inspection of the platform, the inspection of the platform shall prevail.

Note: It is recommended to use intelligent detection systems to improve the accuracy and efficiency of inspection.

Inspection methods for clothing interlinings

Inspection of local defects

Defect braiding method

Different defects are distinguished by wearing different colored threads or marking the edges of the fabrics. Minor defects and defects that do not affect the appearance of the garments will not be visible after being covered with standard fabrics that meet FZ/T01076.

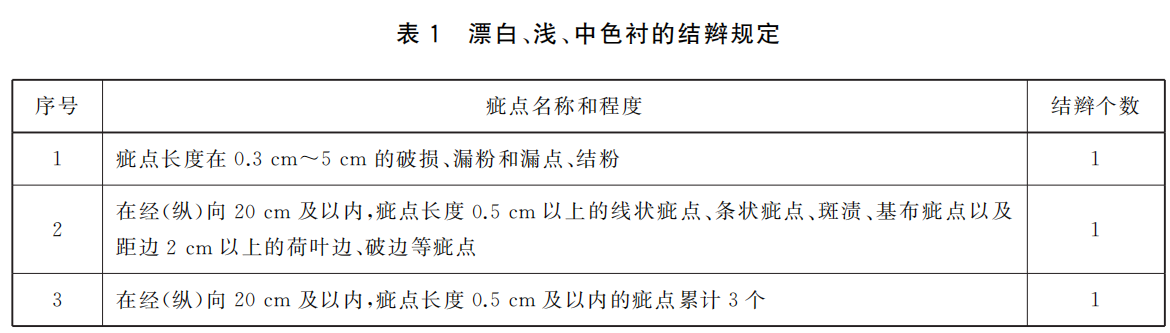

The braiding regulations for bleached, light and medium color linings are as per Table 1.

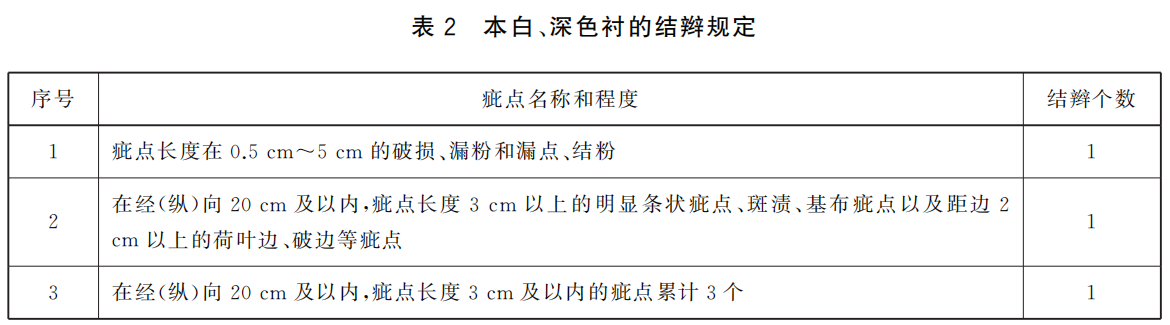

The braiding regulations for natural white and dark linings are as per Table 2.

The braiding regulations for natural white and dark linings are as per Table 2.

Superior and first-class products should not have any damaging defects.

Superior and first-class products should not have any damaging defects.

The specific contents of fabric defects are in Appendix A, and the description of defect names is in Appendix B.

Defect marking regulations

If the length of the warp (longitudinal) defect exceeds 5cm to 20cm, an additional length of 10cm will be added. If the length of the warp (longitudinal) defect is less than 5cm, no ruler will be added.

For each seam allowance, add 20cm to the length.

Add one piece of joint and add 20cm to the length.

The difference between slight and obvious defects

The distinction between slight and obvious defects of bleached lining is made according to GB/T250 by single-layer inspection and assessment: Grade 4 and above are slight, Grade (3-4) and below are obvious, or defects visible at a distance of 60cm from the fabric surface are obvious defects.

The distinction between slight and obvious defects of white, light, medium and dark linings is made according to GB/T250 by single-layer inspection and assessment: (3-4) and above are slight, 3 and below are obvious, or defects visible at a distance of 60cm from the fabric surface are obvious defects.

Provisions for defect handling

Defects that exceed the braiding range should be cut; excessive or uneven gluing should be cut.

Slight or obvious continuous linear defects in the warp and weft (longitudinal and horizontal) directions; slight continuous strip defects with a width of 0.3cm~5cm in the warp and weft (longitudinal and horizontal) directions; except for torn edges and unglued edges, continuous defects within 4cm from the edges, the downgrade limit is qualified products.

The laminated adhesive lining is not allowed to bubble or peel off easily.

The powdering of adhesive interlining shall comply with the provisions of FZ/T60034.

Needle-punched nonwoven linings should not have holes, scorching, compaction, or residual metal needles.

Inspection of scattered defects

The inspection method for scattered defects shall be carried out according to the severity of the defects and the overall effect on the appearance, in combination with the product standards.

Defect meter

The length of defects shall be measured according to the maximum length in the warp and weft (vertical and horizontal) directions. When various defects exist at the same time, they shall be measured and scored cumulatively. Overlapping defects shall be measured according to the severity.

For scattered stains that are difficult to count and measure, they shall be measured separately according to their maximum length and width, and the scores shall be accumulated. When inspecting double-sided adhesive lining, both sides shall be inspected separately and the defects shall be calculated together.

Defects not listed in this document shall be braided, cut, cut and reduced according to similar defects. Special varieties or special requirements of users shall be agreed upon in the sales contract between the supply and demand parties.

Share this product

Textile Inspection

Garment interlining is an auxiliary material used for the internal structure support and shaping of clothing, and is widely used in suits, shirts, coats, skirts and other types of clothing. Its main function is to enhance the stiffness, stability and durability of clothing, making the finished garment more three-dimensional and with a good wearing effect.