Honeycomb cardboard box inspection requirements and methods

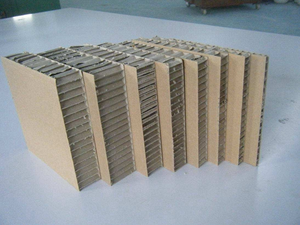

Honeycomb paperboard boxes are packaging boxes made of paper materials with a honeycomb structure. Its design is inspired by the hexagonal structure of the honeycomb. This honeycomb structure provides excellent strength and support while reducing the use of materials, making honeycomb paperboard boxes light and environmentally friendly. They are widely used in industrial packaging, home appliance packaging, agricultural products and food packaging, e-commerce express packaging and other logistics and warehousing fields.

Classification and basic box types

Classification

Honeycomb paperboard boxes can be divided into light honeycomb paperboard boxes and heavy honeycomb paperboard boxes according to thickness. The classification of honeycomb paperboard boxes is shown in Table 1.

Table 1 Honeycomb paperboard box classification unit is millimeter

|

Serial number |

Classification |

Honeycomb paperboard thickness |

|

1 |

Light honeycomb cardboard box |

≤10 |

|

2 |

Heavy honeycomb cardboard box |

>10 |

Basic box type

The basic types of honeycomb paperboard boxes are:

a) Slotted type

It is composed of several pieces of cardboard, which are boxed by slotting, gluing, etc. It can be transported in bulk and laid flat, and assembled into boxes on site when used;

b) Fitting type

A honeycomb carton made up of several pieces of box blanks, which is characterized by the box bottom, box cover and other parts being separated, and the box cover, box bottom and other parts being put together to form a honeycomb carton when in use;

c) Folding type

It is usually composed of one or two pieces of honeycomb cardboard, with the top and bottom folds (also called upper and lower flaps) forming the box cover and bottom, which are made into a box by stapling or gluing. It can be folded flat during transportation and the box cover and bottom must be sealed when in use.

The basic box structure diagram of the honeycomb paperboard box is shown in Appendix A. In practical applications, other types of honeycomb paperboard boxes can also be used according to different contents.

Appearance requirements for inspection of honeycomb cardboard boxes

Visual inspection under natural light.

The surface of the honeycomb paperboard box should be clean and flat, without cracks, and should not have defects such as bubbling, degumming, oil stains, and damage.

The box should be square, and there should be no obvious warping, dents or other deformations on each surface. The markings should be clear and accurate.

The edge sealing should be firmly bonded, smooth and free of bubbles.

The content, color tone, position and font of the printed page should be consistent with the requirements. The patterns and texts should be clear and the positions should be accurate. There should be no sticking or accumulation of printing ink.

Honeycomb cardboard box inspection material requirements

Honeycomb paperboard materials should comply with the provisions of BB/T0016. The strength index of honeycomb paperboard sampled for testing after boxing can be reduced by 10% of the standard value, and the moisture content of honeycomb paperboard sampled for testing after boxing should comply with (14±4)%.

The honeycomb paperboard boxes should be nailed together using galvanized or copper-plated low-carbon steel flat wires with a width of more than 1.5mm and anti-rust treatment. The flat wires should not have spots, peeling, cracks or other defects caused by use.

Adhesives with sufficient bonding strength that comply with GB/T31818, HG/T2727, and HG/T3698 should be used to bond honeycomb paperboard boxes.

Other materials used in honeycomb paperboard boxes should comply with relevant standards or regulations.

Honeycomb cardboard box inspection size requirements

The inner and outer dimension deviation of the light honeycomb paperboard box is ±5mm.

The inner dimension deviation of heavy honeycomb paperboard boxes is shown in Table 2.

Table 2 The inner dimension deviation of heavy honeycomb paperboard box is in millimeters

|

Serial number |

Inner Dimensions |

deviation |

|

1 |

<500 |

±5 |

|

2 |

500~1000 |

±6 |

|

3 |

>1000 |

±7 |

Honeycomb cardboard box inspection quality and structural requirements

The combination can be glued or nailed together. The quality should be uniform, and there should be no defects that affect the use, such as poor bonding and nailing, irregularities, dirt, scars, etc.

The width of the lap tongue of the nailed joint shall not be less than 35mm, the interval of the nails shall not be more than 80mm for a single nail and not more than 110mm for a double nail, and the nailing shall be done along the center line of the overlapped part, using oblique nails (about 45° to the vertical edge of the honeycomb paperboard box) or horizontal nails. The distance between the head and tail nails and the center line of the bottom indentation shall be 13mm±7mm. The nailed seams of the honeycomb paperboard box shall be nailed firmly and through, and there shall be no defects such as overlapping nails, warped nails, and no corners.

The width of the lap edge of the bonded joint shall not be less than 35mm. The adhesive of the bonded joint shall be applied evenly and fully, and there shall be no adhesive overflow. The bonding shall be firm, and at least 70% of the bonded surface shall be destroyed when peeling.

The fold line should be centered, there should be no cracks or breaks, and there should be no extra indentation lines on the box wall.

The swing cover should be firm and able to withstand multiple opening and closing. After testing, there should be no cracks on the surface layer, and the total length of cracks in the inner layer should not exceed 50mm.

Except for special-shaped boxes, the cut parts and edges of each surface of the honeycomb paperboard box should be at right angles to each other. The molding deviation of the honeycomb paperboard box is shown in Table 3.

Table 3 Honeycomb paperboard box molding deviation unit is millimeter

|

Serial number |

Sum of inner dimensions |

The difference between the top and bottom diagonals |

|

1 |

≤1000 |

≤7 |

|

2 |

>1000 |

≤13 |

The surface of the honeycomb paperboard should not be cracked during indentation and closing, and the center seam should be 3mm to 8mm after the two covers are flattened.

The hole in the box corner should not exceed 4mm. There should be no obvious defects in the cut part.

Physical performance requirements for honeycomb cardboard box inspection

Moisture content

The moisture content of honeycomb paperboard box is (14±4)%.

Empty box compression

The measured value of the empty container pressure resistance test should not be less than the pressure resistance value P, which is calculated according to formula (1):

P=K×m×(H/h-1)×g……………………(1)

Where:

P ——pressure resistance value, in Newton (N);

K ——deterioration coefficient, see Table 4;

m ——the mass of a single package, in kilograms (kg);

H ——stacking height, in meters (m);

h——height of the package, in meters (m);

g ——gravitational constant, taken as 9.8N/kg.

Table 4 Deterioration coefficient

|

Classification |

Light honeycomb cardboard box |

Heavy honeycomb cardboard box |

|

Deterioration coefficient K |

2 |

3 |

|

Note: The above are standard values and can be agreed upon by both the supplier and the buyer. |

||

Other features

The stacking, dropping and vibration tests of honeycomb paperboard boxes should match their contents, packaging protection methods, etc. The technical parameters and performance requirements can be agreed upon by both the supply and demand parties.

Honeycomb cardboard box inspection size inspection method

Light honeycomb cardboard box

Use a measuring tool with an accuracy of 1 mm to measure. When measuring the inner dimensions, the carton should be stretched out to form a 90° angle between the adjacent faces of the carton. Measure the length and width at the point 50 mm from the flap indentation on the flap, and measure the height of the carton at the distance between the two inner flaps at the bottom and top of the carton.

Heavy honeycomb cardboard box

The measurement is carried out with a measuring tool with an accuracy of 1 mm. If the heavy honeycomb paperboard boxes are processed by die cutting (or slotting), creasing, stapling (or gluing), etc., they can be inspected as light honeycomb paperboard boxes.

Honeycomb paperboard box inspection quality and structure inspection method

The bonding parts of the honeycomb paperboard box are peeled off by hand. If there is obvious adhesion between the face papers at the peeling point, the face papers are damaged. Calculate whether the ratio of the damaged area of the face papers to the bonding area meets the standard.

The flap of the honeycomb paperboard box is closed and then opened 180° back and forth 5 times to check whether there are cracks on the surface layer and the inner layer. The cracks are measured with a measuring tool with an accuracy of 1mm.

Appendix A Schematic diagram of the basic box structure of honeycomb paperboard box

A.1 Slotted type

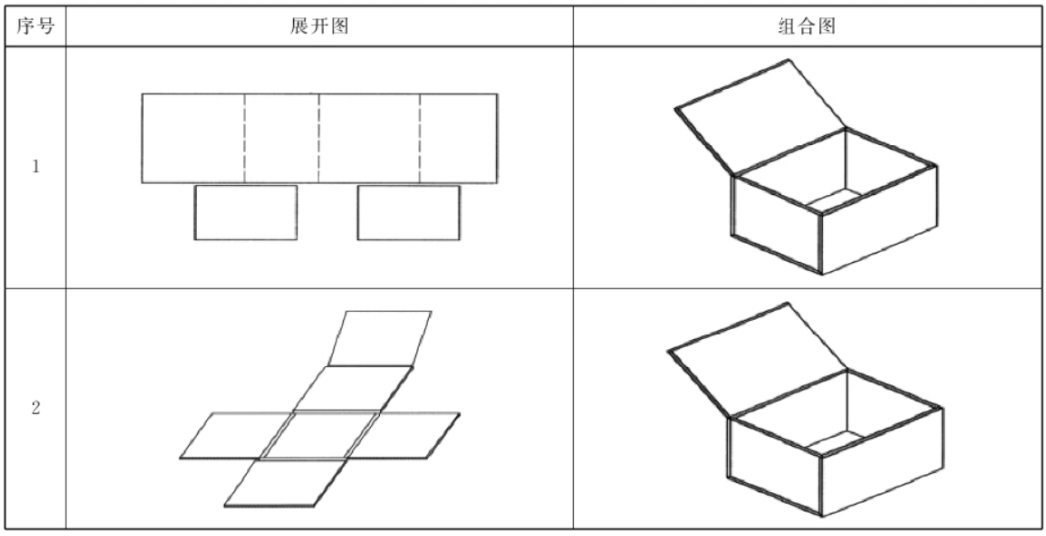

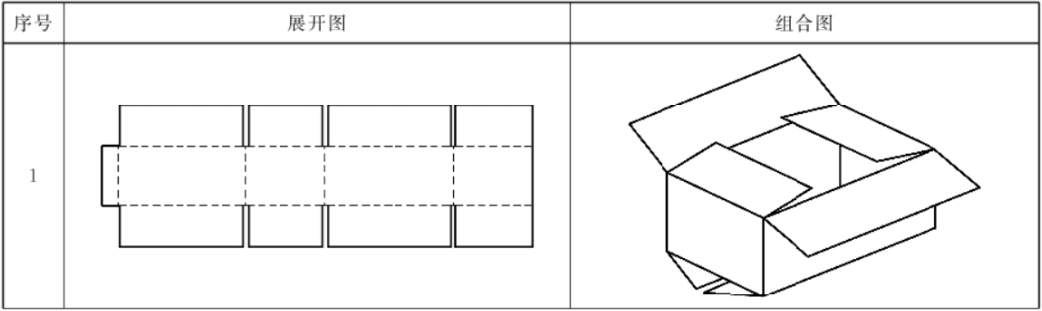

See Table A.1 for the slotted type expansion diagram and combination diagram.

Table A.1 Grooved type development and combination drawings

A.2-piece type

See Table A.2 for the nested combination diagram.

Table A.2 Combination diagram of nested type

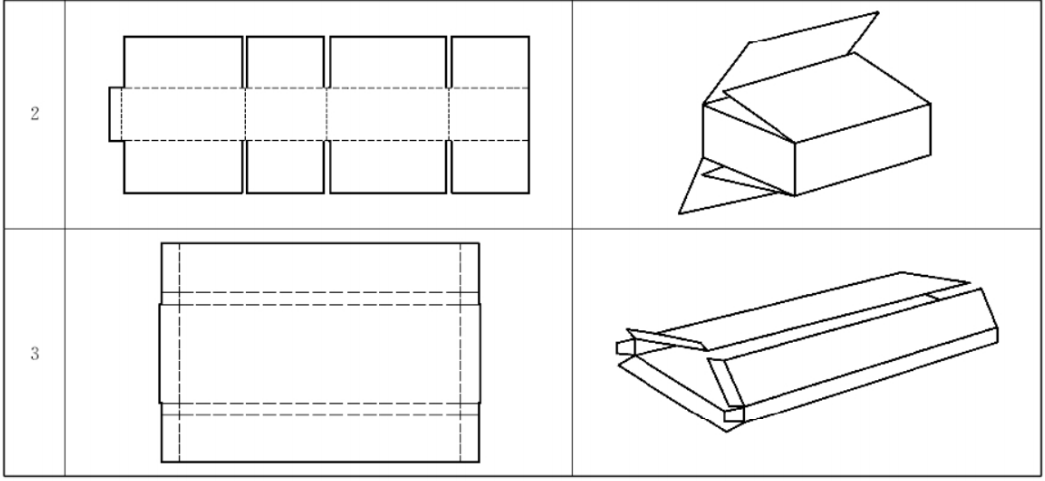

A.3 Folding type

The folded expansion diagram and combined diagram are shown in Table A.3.

Table A.3 Folding expansion diagram and combination diagram

Share this product

Honeycomb cardboard box inspection requirements and methods

Honeycomb paperboard boxes are packaging boxes made of paper materials with a honeycomb structure. Its design is inspired by the hexagonal structure of the honeycomb. This honeycomb structure provides excellent strength and support while reducing the use of materials, making honeycomb paperboard boxes light and environmentally friendly. They are widely used in industrial packaging, home appliance packaging, agricultural products and food packaging, e-commerce express packaging and other logistics and warehousing fields.