What are the categories of quality defects? How to judge?

Why is it so important to clearly define and classify product quality defects?

Let's say you produce women's shirts in Indonesia, and a third-party inspection report shows that about one-third of the shirts have untrimmed threads. Would you classify this as a "minor" or "major" defect? You might consider untrimmed threads a "minor" defect that does not affect the saleability of your product, but if your product is sold to high-end retailers with lower quality tolerance, it might be considered a "major" defect.

This article will analyze the general methods for classifying defects in different products to help you establish a scientific classification system.

What is defect classification?

Defect classification is a critical step in determining whether a shipment passes inspection. By assessing the number and severity of defects, you can make informed shipping decisions.

Professional inspection companies usually have developed defect classification standards for specific product types, but as a buyer, you ultimately have to decide how much tolerance you have for different defects. A common tool used is the Acceptable Quality Limit (AQL).

Three types of defect classification

Quality control experts usually classify quality defects into the following three categories, depending on their nature and severity:

- Minor defects : usually cosmetic flaws that do not pose a serious problem

- Serious defects : may affect product functions or performance, please be careful

- Key flaw : There are safety risks and zero tolerance is required

Brands and retailers can set the tolerance for each type of defect, which directly affects the sampling volume during inspection. Importers often set tolerances through AQL sampling.

Minor defects

Minor defects are usually minor problems that do not affect the function or form of the product. Customers may not notice such defects and will not return the goods. Importers usually set a higher AQL tolerance for minor defects, but if the number of defects exceeds the limit, the entire batch of goods may still be judged as unqualified.

Serious flaws

Major defects are significant deviations from the buyer's specifications and may affect function, performance or appearance. Such defects are easily noticed by customers and may lead to returns, complaints or refunds. Importers have a lower tolerance for such defects and will usually ask suppliers to rework or reject the goods if inspection reveals too many major defects.

Key flaws

Critical defects are the most serious type and may render the product completely unusable or cause harm to the user. Such defects may trigger high-risk events such as product liability lawsuits and recalls. Importers usually adopt a zero-tolerance policy for critical defects. If a critical defect is found during inspection, the entire batch of goods will be deemed unqualified.

Examples of quality defects in different products

The types of defects for different products vary depending on the material, production process and standards. The following are examples of common defects for several types of products:

Soft Products

Soft products include textiles, clothing, footwear, etc. Clothing relies on manual sewing, and the following defects are prone to occur during the production process:

- Minor defect : thread ends not trimmed (can be solved by simple rework, but may be considered a serious defect by high-end customers)

- Serious defects : Missed stitches (caused by sewing machine failure or operating errors, affecting appearance and seam strength)

- Key defect : Sewing needles remain in the finished product (a safety hazard, and if found during inspection, the product will be deemed unqualified)

Hard Products

Hard products include furniture, kitchenware, building materials and other metal/wood/plastic products. Common defects include:

- Minor defects : Minor surface scratches (does not affect saleability)

- Serious defect : Deep scratches on the brand logo (difficult to repair, damaging the brand image)

- Key defect : Sharp burrs (may scratch users, leading to recalls)

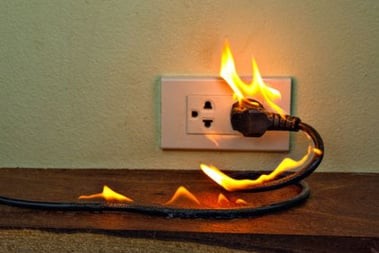

Electronics and electrical products

Common defects of electronic and electrical products:

- Minor defects : wipeable surface stains

- Serious defects : functional failure (such as failure to boot, abnormal display)

- Key defect : Broken wires (exposed copper wires, posing a risk of electric shock or fire)

Industrial Parts

Examples of defects in industrial parts (e.g. steel pipes, valves, turbines):

- Minor defect : welding protrusion (does not affect the function)

- Serious defects : non-critical dimensional deviations (may affect subsequent assembly)

- Key defects : rust (indicating premature product failure, such as rust on water and gas pipes)

Defect Classification in Quality Control Checklist

The inspection company can suggest defect tolerances, but ultimately it is up to the buyer to specify the standards in the quality control checklist (QC Checklist).

A complete defect classification table can:

- Help suppliers to conduct self-inspection and correct defects in advance

- Ensure that inspection results meet your quality expectations

- Reduce "pending" results due to vague standards

How to deal with quality defects in products

If a defect is found during pre-shipment inspection, you can take the following actions:

- Request suppliers to rework or replenish goods

- Re-inspect to confirm defects have been resolved

- Deduction claim (if agreed in the contract)

- Destroy unsalable goods (to prevent defective goods from entering the gray market)

The defect classification table needs to be continuously updated and tolerances adjusted according to new orders.

Supplementary criteria for defect classification

Inspection companies usually follow general guidelines, but buyers need to adjust the classification according to brand and customer needs. If the inspection company's classification does not meet your standards, you should provide feedback in time to optimize the accuracy of subsequent reports.

Share this product

What are the categories of quality defects? How to judge?

You produce women's shirts in Indonesia, and a third-party inspection report shows that about one-third of the shirts have untrimmed threads. Would you classify this as a "minor" or "major" defect? You might consider untrimmed threads a "minor" defect that does not affect the saleability of the product, but if the product is sold to high-end retailers with lower quality tolerance, it might be considered a "major" defect.