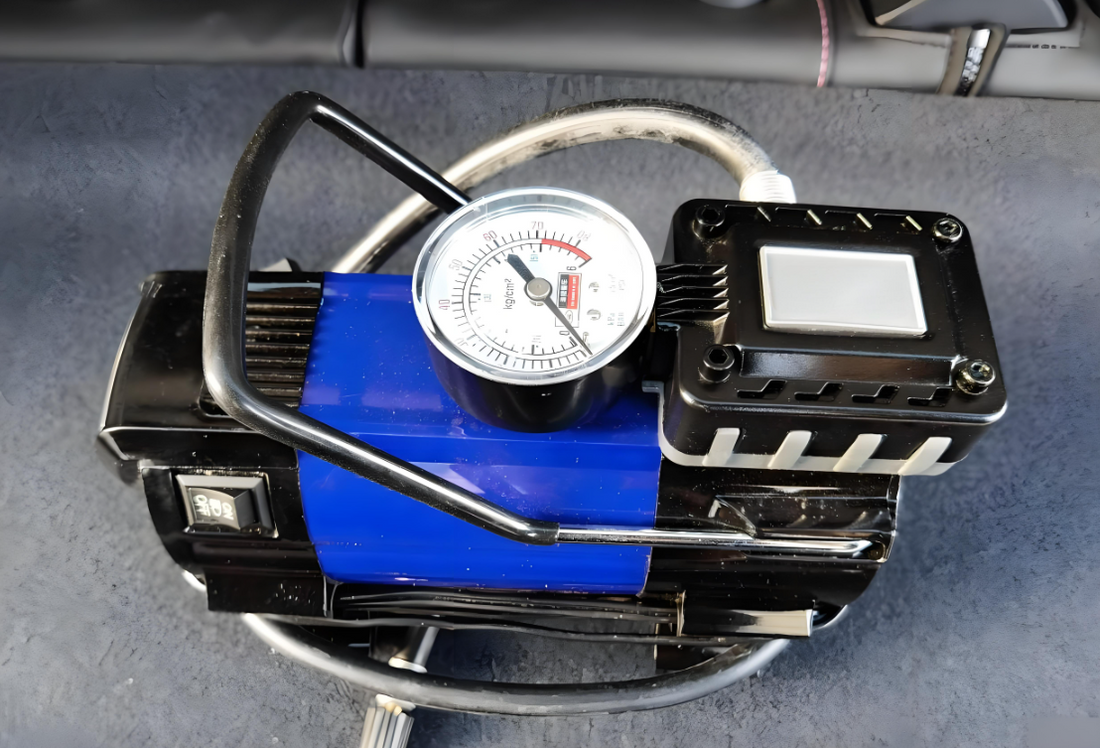

Full inspection of vehicle air pumps, inspection standards and methods for vehicle air pumps

When a car's tires are under-inflated, it can pose a safety hazard to the car. Therefore, a car air pump that can be used with the car is very convenient, practical, and necessary. Currently, there are many types of car air pumps sold on major e-commerce platforms, with varying prices and relatively varying quality.

How do third-party professional inspectors inspect vehicle charging pumps on various e-commerce platforms? What are the standards and methods for inspecting vehicle charging pumps?

First, it is necessary to inspect the appearance and workmanship, quantity, product, packaging/marking/labeling of the on-board charging pump.

Secondly, the most important thing is the data measurement and on-site testing done by the inspector on site.

-

Shipping drop test (not for fragile products)

Perform drop test according to ISTA 1A standard. After 10 drops, the product and packaging should have no fatal or serious problems. -

Product size/power cord length/product weight measurements <br>Based on product specifications and approved samples, if customer does not provide detailed tolerance or tolerance requirements, a tolerance of +/- 3% will apply.

-

Full functional inspection (including functions that must be assembled)

Functions such as installation, adjustment, switches/knobs, settings, displays, and usage should all function properly. All functions should be as stated. -

Coating adhesion test <br>Use 3M 600 adhesive tape to perform adhesion test on spray painting, hot stamping, UV coating, and printing. No more than 10% of the content should fall off.

-

Power on inspection <br>Power on the sample board with rated voltage and operate at full load for at least 4 hours or as per the instructions (if less than 4 hours). After the test, the sample board should be able to pass the high voltage test, function test, ground resistance test, etc., and there should be no defective junction test.

-

Power consumption check or input power/current check <br>Power consumption/input power/current should comply with product specifications and safety standards.

-

Power cord pull test

IEC standard: Pull 25 times, no more than 1KG, pull 30N, more than 1KG, no more than 4KG, pull 60N, more than 4kG, pull 100N. The wire displacement after pulling does not exceed 2mm. UL standard: Pull 35 pounds for 1 minute, no wire displacement. -

Internal workmanship and key component inspection <br>Inspect internal structure and key components according to CDF or CCL.

-

Printing, logo, nameplate adhesion test <br>Wipe the rated sticker with a cloth dipped in water for 15S, then wipe it with a cloth dipped in gasoline for 15S, there should be no defect.

-

Stability test (applicable to vertical products)

The product is placed on an inclined surface at 10 degrees to the horizontal plane (15 degrees for heating appliances) as in normal use. The power cord should be placed in the most unfavorable position and the appliance should not fall over. -

Low voltage starting check <br>It can start normally at 90% of the rated voltage.

-

Lock motor inspection <br>The product is set to high gear, working at rated voltage, and the motor is locked. The product cannot pose a hazard to the user and the surrounding environment, and there must be no ignition, burning of shell materials, or melting of metal.

-

Pressure check <br>The pump outlet air pressure should meet the specifications

-

Inflation check <br>Inflate according to the instructions and leave it for 2 hours. There should be no leakage or other problems.

-

Battery voltage test <br>According to battery marking

-

Working temperature check <br>according to the instruction manual

-

Working noise check <br>According to the instruction manual

When the product is 100% completed, before or after packaging, we will inspect each product's appearance, workmanship, function, safety, and other customer-specified checkpoints at our full inspection factory or at a customer-specified location, strictly distinguishing between good and defective products and reporting the inspection results to the customer in a timely manner.

Share this product

Full inspection of vehicle air pumps, inspection standards and methods

When a car's tires are under-inflated, it can pose a safety hazard to the car. Therefore, a car air pump that can be used with the car is very convenient, practical, and necessary. Currently, there are many types of car air pumps sold on major e-commerce platforms, with varying prices and relatively varying quality.