Knitted underwear inspection

Knitted underwear is a kind of close-fitting clothing made of knitted fabrics. It is deeply loved by consumers because of its softness, good elasticity and strong breathability. Knitted fabrics are made of yarn coils, with a moderate structure, which can fit the body curve and provide good wrapping and comfort. Knitted underwear includes men's, women's and children's styles. Common categories include vests, underwear, thermal underwear, camisole, etc., which are suitable for wearing in spring, summer, autumn and winter. Modern knitted underwear pays attention to the selection of materials. It mostly uses environmentally friendly and healthy fabrics such as pure cotton, modal, bamboo fiber, and spandex blends. It is not only skin-friendly and non-irritating, but also has moisture absorption and perspiration, antibacterial and deodorizing functions. High-quality knitted underwear is well-cut, with smooth seams, close-fitting and not tight, suitable for long-term wear, and effectively improves the comfort in daily life. As an important part of people's daily clothing, knitted underwear not only meets basic wearing needs, but also pays more and more attention to fashion and functionality.

Inspection requirements for knitted underwear

Grading rules

The quality grades are divided into superior products, first-class products and qualified products.

Internal quality is graded by criticism, and appearance quality is graded by piece. The combination of the two is used to determine the lowest grade.

For each intrinsic quality index, the lowest test result will be used as the basis for rating the batch of products.

When the appearance quality problems of different grades are found on the same product, the lowest grade shall be evaluated. Only two limit surface defects of the same grade are allowed on the same product, and if more than two limit surface defects are found on the same product, the grade shall be reduced by one grade.

Intrinsic quality requirements

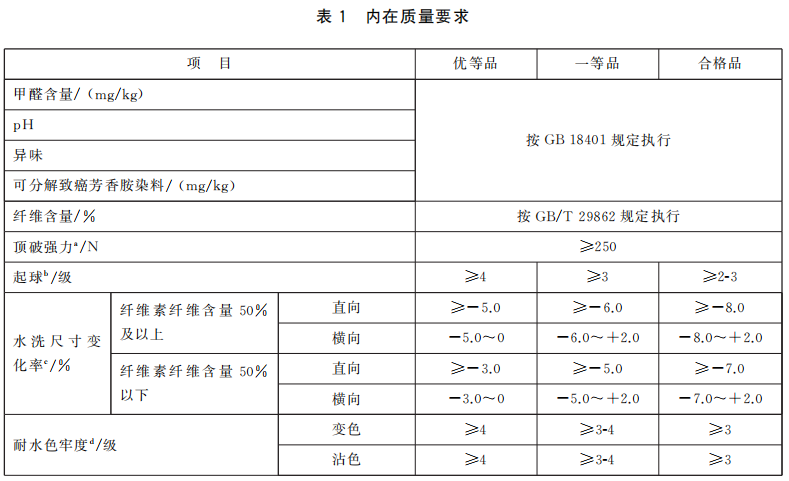

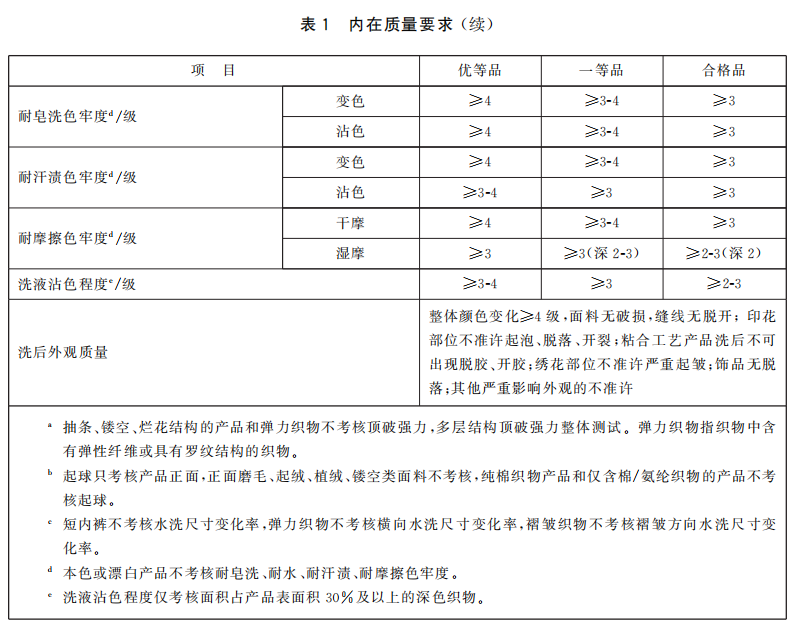

The intrinsic quality requirements are shown in Table 1.

The color classification is based on GSB16-2159, >1/12 standard depth is dark color, ≤1/12 standard depth is light color.

Children's underwear should also comply with the relevant requirements of GB31701.

Appearance quality requirements

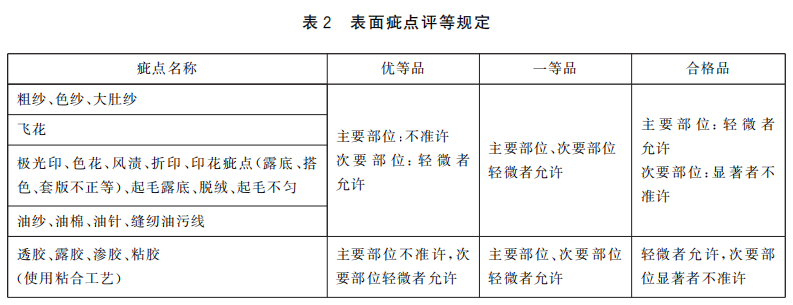

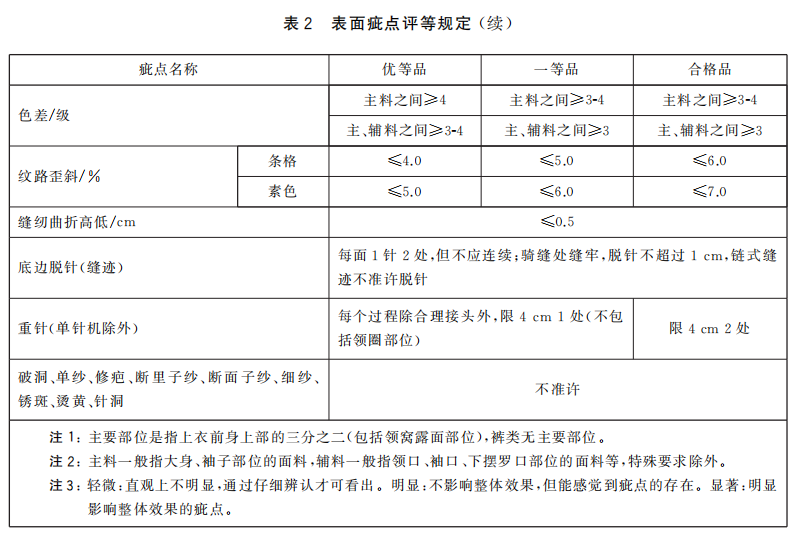

Surface defect evaluation, etc.

The provisions for surface defect evaluation are shown in Table 2.

Any surface defects not specified in the provisions shall be handled in accordance with similar defects.

The length and number of surface defects are both maximum limit values.

The degree of surface defects shall be in accordance with GSB16-2500.

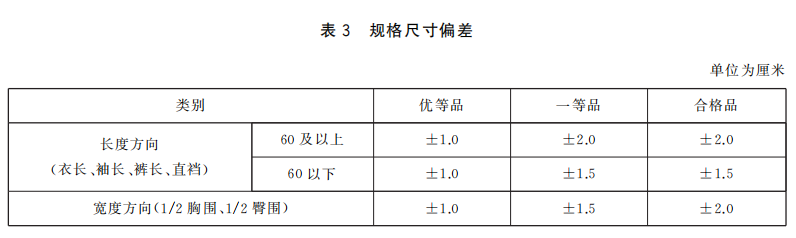

Specification size deviation

Specification size deviation see Table 3

Symmetrical size differences

The size differences of symmetrical parts are shown in Table 4

Knitted underwear inspection test

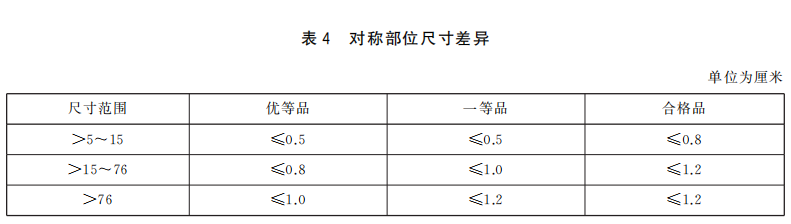

Dimensional change after washing

Measurement area

For tops, the average of the length of the front and back is used as the basis for calculation, and the horizontal measurement of the front is used as the basis for calculation; for pants, the average of the length of the left and right pants is used as the basis for calculation, and the average of the 10cm under the crotch is used as the basis for calculation. Marks should be made during measurement to facilitate measurement after washing. The measurement parts of tops are shown in Figure 1, the measurement parts of pants are shown in Figure 2, and the measurement parts of vests are shown in Figure 3.

Measurement instructions

See Table 5 for instructions on washing size measurements.

Washing and drying

Washing: According to GB/T8629-2017 (A-type standard washing machine, washing program adopts 4N, using standard detergent 3, and drying method adopts program A); products marked "hand wash" shall be in accordance with GB/T8629-2017 (A-type standard washing machine, washing program adopts 4H program, using standard detergent 3, and drying method adopts program A). Number of test pieces: 3 pieces.

Drying: Use the hanging drying method. Use a pole to pass through the sleeves of the top, so that the chest hanging shoulder area is kept straight, and the two pieces are separated and straightened by hand from the bottom; fold the pants in half and hang them to dry, so that the crotch part is on the pole, and gently straighten it. Place the dried sample on a platform at a temperature of (20±2)℃ and a relative humidity of (65±4)%, let it stand for more than 4 hours, gently pat the creases flat, and then measure.

Calculation and expression of results: Calculate the vertical or horizontal dimensional change rate after washing according to formula (1), with a negative sign (-) indicating dimensional shrinkage and a positive sign (+) indicating dimensional elongation (reverse expansion). The arithmetic mean of all samples is taken as the test result. If there are both shrinkage and elongation (reverse expansion) test results, the arithmetic mean of the two shrinkage or elongation samples is taken as the test result. The final result is rounded according to GB/T8170 and one decimal place is retained.

Degree of staining of lotion

Prepare and wash the sample according to method A (1) in GB/T3921-2008, then filter with qualitative filter paper (medium speed) to remove impurities in the residual soap solution, and pour the filtered soap solution into a colorimetric tube with a diameter of 25 mm. Pour the unwashed soap solution with the same temperature as the test temperature into another colorimetric tube (diameter 25 mm) as a reference sample. Under D65 standard light source, with white cardboard without fluorescent brightener as the background, the cardboard is placed on the rating rack, and the degree of staining of the washing solution is evaluated according to GB/T251. The amount of soap solution poured into the colorimetric tube is about 50 mL. During the rating, the distance between the colorimetric tube and the white cardboard is about 10 cm to avoid interference from the shadow of the colorimetric tube. The rating must be completed within 15 minutes.

Appearance quality after washing

Wash and dry the underwear according to the test method for dimensional change after washing in this document, and evaluate the underwear after washing according to the requirements of Table 1.

Appearance quality inspection conditions

Generally, the inspection is conducted under a light source with an illumination of not less than 600lx. If natural light is used indoors, natural northern light shall prevail. During the inspection, the product shall be laid flat on the inspection table with a layer of white cloth on the table. The inspector shall look directly at the surface of the flat product, with the eyes at least 35cm away from the product.

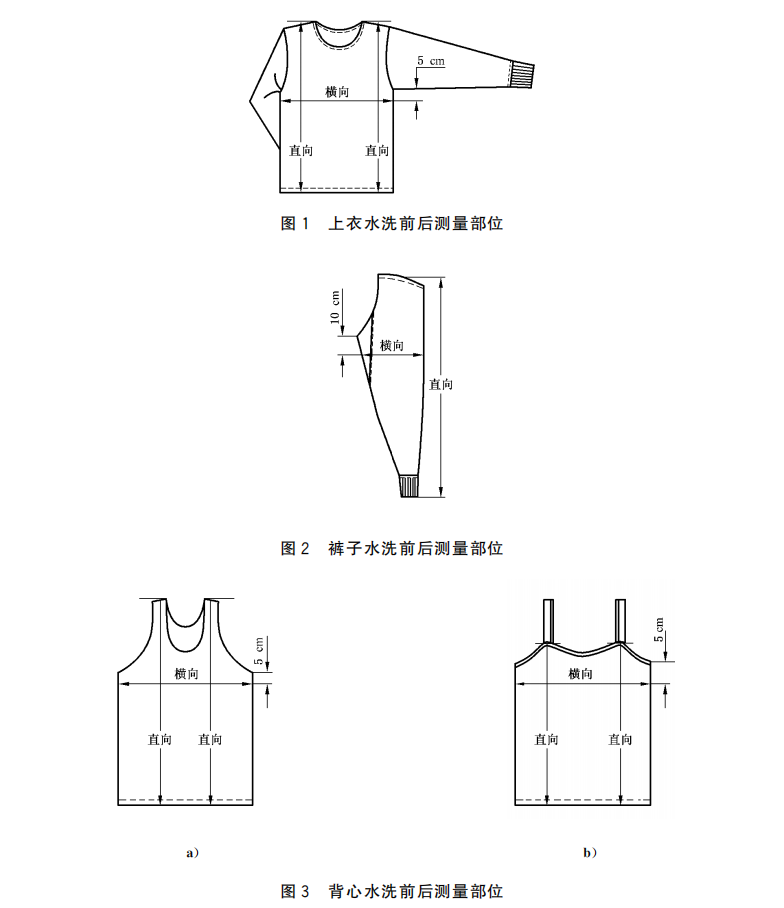

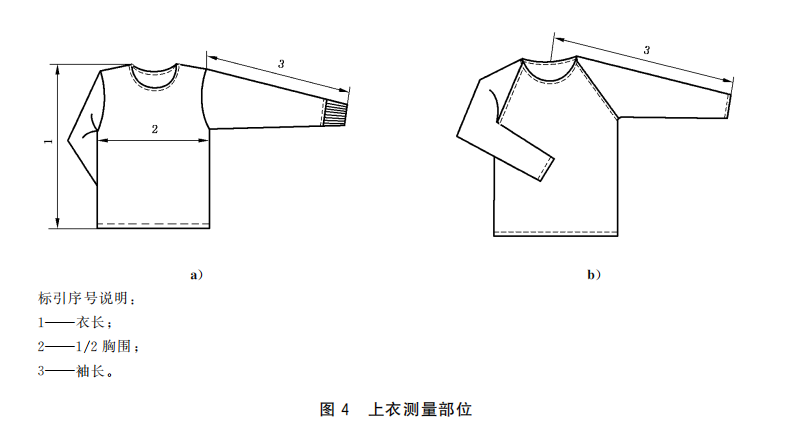

Measurement location and regulations

See Figure 4 for the measurement areas of the top.

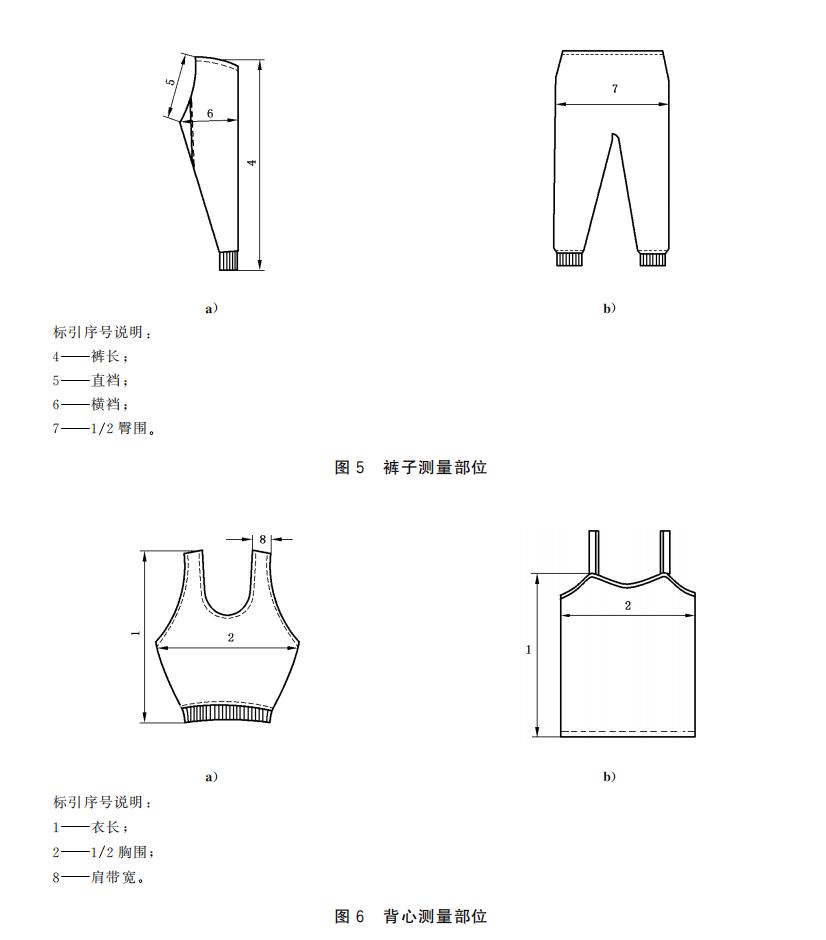

See Figure 5 for the measurement areas of the pants.

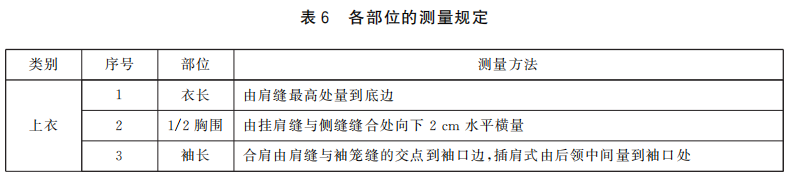

The measurement area of the vest is shown in Figure 6.

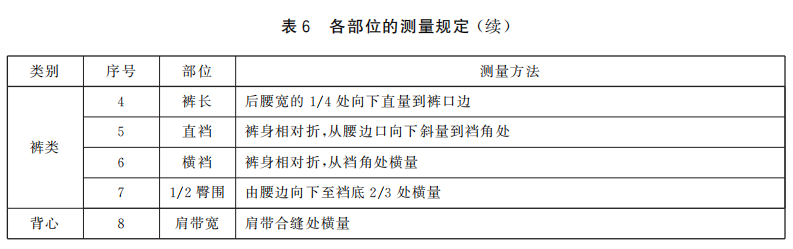

The measurement regulations for each part are shown in Table 6, and the measurement values are accurate to 0.1cm.

Share this product

Knitted underwear inspection

Knitted underwear is a kind of close-fitting clothing made of knitted fabrics. It is popular among consumers for its softness, good elasticity and strong breathability. Knitted fabrics are made of yarn loops, with a moderate tightness, which can fit the body curves and provide good wrapping and comfort.