[Inspector Encyclopedia] Common quality issues of plugs and sockets. Provide professional inspection, factory inspection, certification and audit services

1. Product Overview and Importance of Inspection

Despite their compact size, plugs and sockets are crucial to electrical safety in countless households. They are essential components for everything from daily household use to industrial production and high-tech applications. According to public security statistics, substandard plug and socket quality has become a major cause of electrical fires in recent years. As a professional inspector, a comprehensive understanding of plug and socket inspection standards and common issues is crucial for ensuring product quality and preventing safety incidents.

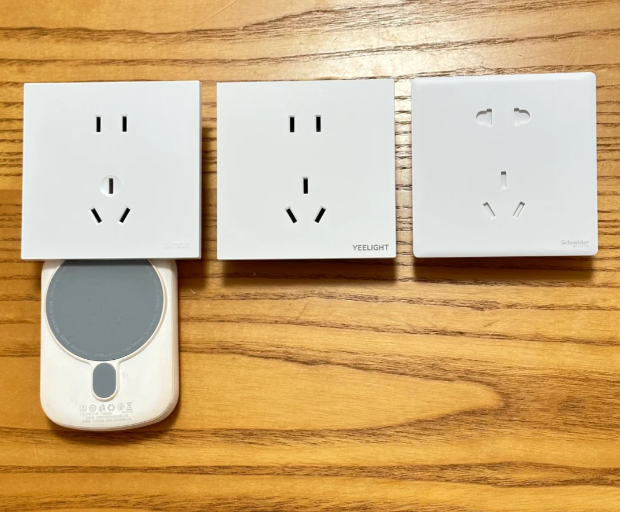

2. Product classification and inspection scope

Before inspection, the product classification of plugs and sockets must be clearly defined so that appropriate inspection plans can be adopted for different types:

-

Plug type : Single-phase two-pole or two-pole grounded (non-removable) plug (Note: two-pole grounded plug is a three-prong plug, and a removable plug refers to a plug with a replaceable flexible cable)

-

Fixed socket : removable threaded terminal two-pole or two-pole with grounding socket, threadless terminal two-pole or two-pole with grounding socket

-

Mobile socket : two-pole or two-pole grounded mobile socket

-

Cord extension kit

-

Appliance socket : Two-pole or two-pole grounded appliance socket

-

Converter : Type converter, (non-)detachable intermediate converter

-

Three-phase four-pole plug or socket

During the factory inspection process, the inspector should first confirm the product type, check the consistency of design and production, and ensure that it complies with relevant national standards and customer technical requirements.

3. Common inspection issues and key points of professional inspection

1. Product structure safety and compliance inspection

Problem manifestation : unreasonable structural design, insufficient elasticity of the socket assembly, and substandard extraction force test

Professional inspection method :

-

Use a professional extraction force tester to measure the connection force between the plug and the socket to ensure compliance with standard requirements

-

Check the distance between the two clamping pieces of the socket to verify whether it can effectively clamp the plug pin

-

Measure the distance between the bottom surface of the socket and the mating surface to ensure full mating and prevent the risk of electric shock.

-

During factory inspection, it is necessary to focus on reviewing the consistency between product structure design drawings and actual products

Quality risk : Poor contact can cause excessive temperature rise, abnormal operation of electrical equipment, and even fire in serious cases.

2. Inspection of cord fixing components and grounding system

Problem manifestation : The cord fixing parts are missing, the grounding socket is not locked or can be removed by hand

Professional inspection method :

-

Checking the integrity of cord retention components on rewirable plugs, portable socket-outlets and rewirable converters

-

Verify that the ground and neutral sockets on portable outlets and rewirable converters are securely locked

-

Confirm that professional tools must be used to remove the socket to prevent unprofessional operation

-

The integrity and reliability of the grounding system must be fully checked during the inspection process

Quality risk : The soft wire can be easily pulled out, causing a short circuit, and the failure of the grounding system increases the risk of electric shock.

3. Flame retardant performance test of insulation materials

Problem manifestation : The material's flame retardancy does not meet the standard and it continues to burn during the glow-wire test.

Professional inspection method :

-

Conduct material flame retardancy tests according to standard requirements and record burning time

-

Verify that the material can self-extinguish 30 seconds after the glow wire is removed

-

During the factory inspection, the flame retardant grade certification documents provided by the supplier should be reviewed

-

Regular sampling and sending to third-party laboratories for compliance verification

Quality risk : Fire cannot extinguish itself when it occurs, and the risk of fire spreading is extremely high

4. Product marking and logo compliance inspection

Problem manifestation : The logo is missing, wrong or does not meet the standard requirements

Professional inspection method :

-

Check the completeness and accuracy of the model mark and power property symbol (~)

-

Verify that the ground symbol complies with national standards (it should be "⏚" instead of "E" or "G")

-

Check whether the converter product is marked with the "MAX (or maximum)" symbol and rated current/power

-

Test the durability of signs to ensure that silk screen and paper signs are not easily erased

-

When inspecting goods, special attention should be paid to the standardization and durability testing of the markings

Quality risk : User misoperation leading to equipment damage or personal injury

5. Terminal connection reliability inspection

Problem manifestation : Terminal design defects, unreliable connection, and easy damage to the thread

Professional inspection method :

-

Check the integrity and structure of the terminal blocks

-

Testing the tightening performance of screw clamp terminals using a torque wrench

-

Verify that the terminal can withstand the specified torque without damage

-

During the factory inspection, the design and manufacturing process of the terminals should be evaluated

Quality risk : overheating due to poor contact, short circuit due to wire core falling off

6. Safety verification of protection against electric shock

Problem manifestation : Anti-electric shock protection design defects, live parts are easily touched

Professional inspection method :

-

Testing protection against electric shock using a standard test finger

-

Verify that the live pins are not accessible when the plug is engaged with the socket

-

Check the position fixity of the latch to prevent misalignment

-

Regularly update test equipment to ensure compliance with the latest safety standards

Quality risk : direct electric shock hazard, serious threat to user life safety

IV. Comprehensive inspection process and quality control points

-

Pre-inspection preparation : review product technical documents, standard requirements and customer special specifications

-

Sampling plan : Develop a scientific sampling plan based on AQL standards to ensure sample representativeness

-

On-site inspection : Combine visual inspection with instrument measurement to comprehensively evaluate product quality

-

Performance test : Conduct necessary electrical performance and safety performance tests

-

Records and reports : record the inspection results in detail and issue professional inspection reports

-

Follow-up : Propose rectification requirements for non-conforming items and track improvement results

5. Key Control Points of Factory Audit

-

Supplier qualification review : assess the quality management system certification status of the manufacturer

-

Production process control : Check incoming raw material inspection, production process quality control and finished product inspection process

-

Testing equipment management : verifying the calibration status and maintenance records of testing equipment

-

Non-conforming product control : review the non-conforming product handling procedures and corrective and preventive measures

-

Traceability system assessment : Check the integrity and effectiveness of the product traceability system

VI. Conclusions and Recommendations

The quality and safety of plug and socket products are of paramount importance. Professional inspection requires a comprehensive application of standards knowledge, inspection techniques, and risk assessment capabilities. Inspectors should:

-

Proficient in relevant product standards and technical specifications

-

Equipped with professional testing equipment and tools

-

Establish a systematic inspection process and judgment criteria

-

Maintain technical communication and quality feedback with manufacturers

-

Continuously update knowledge and adapt to the requirements of new technologies and new standards

Through strict inspection procedures and professional inspection methods, we can effectively identify and control the quality risks of plug and socket products, provide consumers with safe and reliable products, and promote the improvement of the quality level of manufacturing enterprises.

Share this product

[Inspector Encyclopedia] Common quality issues of plugs and sockets. P

Despite their compact size, plugs and sockets are crucial to electrical safety in every household. They are essential components for everything from daily use to industrial production and high-tech applications. According to public security statistics, substandard plug and socket quality has become a major cause of electrical fires in recent years.