How to use the inspector's dial indicator correctly Inspection, factory inspection, inspection and certification services

1. The importance of precision measurement in inspection work

Precision measuring tools are essential equipment for QC personnel during product quality inspection and factory audits. As a high-precision measuring instrument, the dial indicator plays a key role in dimensional verification, geometric tolerance testing, and process evaluation. Mastering the correct use of the dial indicator not only improves the accuracy of inspection data but also provides a reliable basis for supplier quality assessments.

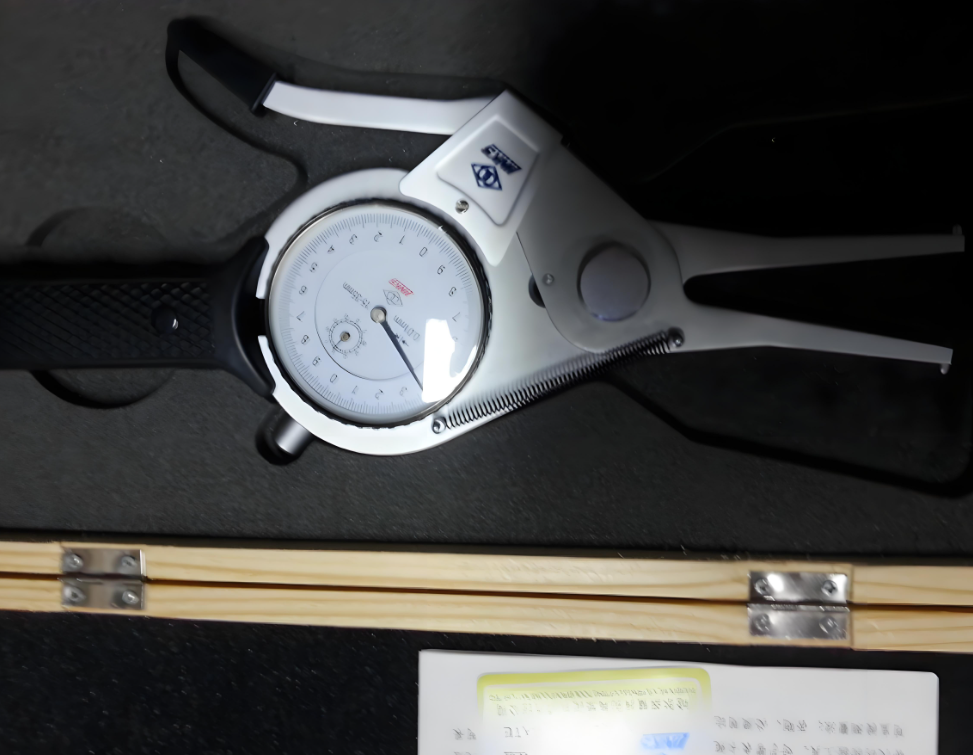

2. Structure and type of dial indicator

1. The structure of ordinary dial indicator

-

Measuring rod : the core component that directly contacts the object being measured

-

Scale disk : The main reading interface showing the measured value

-

Long pointer : indicates the measured value with an accuracy of 0.01mm

-

Revolution pointer : Auxiliary indicator for recording whole millimeter displacement

-

Shell structure : protective device to protect the internal precision parts

2. The special structure of the lever dial indicator

-

Spherical probe : suitable for measurement needs in narrow spaces

-

Commutator : A practical design that allows measurement direction to be switched

-

Rotatable probe : provides the flexibility of multi-angle measurement

-

Symmetrical dial : easy to read in positive and negative directions

3. Application scope of dial indicator in inspection scene

1. Dimensional accuracy verification

-

Mechanical parts processing dimension detection

-

Assembly clearance and fit tolerance measurement

-

Precision measurement of thickness and height difference

2. Geometric tolerance inspection

-

Flatness and parallelism testing

-

Circular runout and total runout measurement

-

Position and coaxiality verification

3. Process quality assessment

-

Process stability monitoring

-

Mold wear condition assessment

-

Production line capability verification

4. Correct reading method of dial indicator

1. Basic reading principles

-

Each rotation of the long needle corresponds to a 1mm displacement of the measuring rod

-

Each scale of the long needle represents 0.01mm accuracy

-

The short hand indicates the whole millimeter value, and the long hand shows the decimal part

2. Step Height Measurement Example

-

Place the probe in contact with the lower surface and adjust the pointer to zero.

-

Move the probe to the upper surface and read the pointer indication value

-

When the long needle points to the 10 scale, the step height difference is 0.10mm

-

When measuring more than 1mm, combine the short needle readings for accumulation

3. Data processing requirements

-

Record measurement environmental conditions (temperature, humidity)

-

Indicate the measurement location and direction

-

Averaging multiple measurements to improve accuracy

5. Correct use of dial indicator

1. Installation and fixing requirements

-

Use a dedicated bracket to ensure stable support

-

Keep the measuring rod perpendicular to the measuring surface

-

Avoid excessive clamping force causing tool deformation

2. Measurement operation specifications

-

The probe needs to gently touch the surface of the object being measured

-

Keep the force consistent when measuring

-

When measuring cylindrical workpieces, ensure that the axis of the measuring rod is consistent with the diameter direction.

3. Things to note during inspection

-

Avoid making precision measurements in vibrating environments

-

Pay attention to the impact of temperature changes on measurement results

-

Clean the probe and the surface to be measured before measurement

6. Professional use skills of lever dial indicator

1. Applicable scenario analysis

-

Measurement of narrow spaces and complex structures

-

Measuring locations that are difficult to access with traditional dial indicators

-

Special workpieces that require multi-directional measurement

2. Operational technical requirements

-

Keep the measuring surface and the probe horizontal (not more than 25° in special cases)

-

Check the wear of the spherical probe before use (if it is worn flat, it needs to be replaced)

-

Adjust the measurement direction through the commutator to meet different needs

-

Rotate the measuring rod so that its axis is perpendicular to the direction of change of the measured dimension

3. Key points for factory inspection application

-

Evaluate the compliance of suppliers' measurement tool management

-

Verify the effectiveness of production line quality control capabilities

-

Check the consistency between process documents and actual measurement results

7. Measurement quality control during inspection

1. Preparation before measurement

-

Check dial indicator calibration status and expiration date

-

Confirm that the measurement environment meets the requirements

-

Prepare standard blocks for on-site verification

2. Measurement process control

-

Adopting unified measurement methods and standards

-

Record measurement conditions and raw data

-

Perform repeatable measurements to ensure reliable results

3. Data Recording and Reporting

-

Use standardized inspection record forms

-

Attached is a diagram and photos of the measurement locations

-

Record the measurement results in detail in the inspection report

8. Maintenance and care specifications

1. Daily maintenance requirements

-

Clean promptly after use and apply anti-rust oil

-

Store in a special tool box to avoid collision

-

Regularly send to professional institutions for calibration

2. Precautions for on-site use

-

Avoid severe impact and drops

-

Prevent cutting fluid and dust from entering the interior

-

Keep the measuring rod free when not in use

3. Calibration and verification

-

Establish and document a regular calibration schedule

-

On-site verification using standard gauge blocks

-

Maintain the integrity and traceability of calibration certificates

IX. Common Problems and Solutions

1. Handling abnormal measurement data

-

Check if the probe is worn or loose

-

Check whether the measuring rod moves smoothly

-

Verify that the bracket is securely fixed

2. Dealing with reading difficulties

-

Clean the dial glass to improve visibility

-

Adjust viewing angle to avoid parallax error

-

Use a magnifying glass to assist in reading fine scales

3. On-site emergency measures

-

Preparation and management of spare dial indicators

-

Mastering simple verification methods

-

Annotation of abnormal data and arrangement of retest

10. Application in the quality management system

1. Tool Management Assessment in Factory Audits

-

Check the integrity of the measurement tool management system

-

Assessing calibration systems and record compliance

-

Verify operator training effectiveness

2. Supplier quality capability assessment

-

Evaluating process stability through measurement data

-

Uncover potential quality issues with precision measurement

-

Support supplier ratings with quantitative data

3. Application in Continuous Improvement

-

Analyze quality trends through precise measurement data

-

Provide data support for process optimization

-

Verify the effectiveness of improvement measures

Summarize

As a crucial precision measurement tool in QC inspection, the correct use of the dial indicator not only impacts the accuracy of individual measurements but also influences the assessment of quality across the entire supply chain. Mastering the professional use of the dial indicator, establishing standardized measurement procedures, and improving the measurement equipment management system are essential qualities for modern quality inspectors. Through meticulous measurement practices, we provide reliable data support for product quality improvement, ultimately achieving continuous improvement in quality control. At China Huibang Focus, we specialize in product inspection and quarantine, testing and certification, supplier background checks, audits, and factory inspections.

Share this product

How to use the inspector's dial indicator correctly Inspection, factor

For every QC, inspection tools are a valuable aid. Besides commonly used tools, it's also important to master the use of more precise tools with narrower applications. While these tools may not be used all the time, it's always good to have more skills, right? Today, Encyclopedia presents how to use a dial indicator. If you find it useful, save it!