Is cross-regional inspection difficult? Global network + digital supervision will help you break through the bottleneck.

With the cross-regional and cross-border development of e-commerce, the activities of inspection, factory verification and certification have become increasingly frequent. However, core issues such as regional differences, high communication costs and regulatory deficiencies have significantly increased the difficulty and risks of cross-regional inspection. These challenges not only lead to low inspection efficiency and uncontrolled quality risks, but also seriously impact the stability of the supply chain, becoming a key bottleneck restricting the expansion of e-commerce scale.

1. Regional Differences: The Hierarchical Contradiction in Qualifications and Execution Capabilities

The primary challenge faced when conducting cross-regional inspections is the "discrepancy" in the qualifications of inspection and certification institutions. In first-tier cities, most institutions possess national-level inspection and certification qualifications, with advanced equipment and professional staff. However, in third- and fourth-tier cities as well as remote areas, a large number of institutions lack formal qualifications and have weak testing capabilities. For instance, a certain cross-border e-commerce company, due to entrusting an unqualified institution for inspection, failed to detect the excessive formaldehyde in furniture and ultimately suffered product recall and heavy regulatory penalties.

Furthermore, there are significant differences in the understanding and implementation of unified inspection standards across various regions. For the same product, the inspection priorities may vary in different areas due to factors such as climate and market customs, resulting in inconsistent inspection results. This forces merchants to prepare multiple sets of inspection lists, significantly increasing operational complexity and return and exchange costs.

II. Communication Costs: Efficiency Bottleneck Due to Spatial Isolation and Information Distortion

Cross-regional inspection involves high communication costs. The time difference issue in cross-border business causes significant delays in communication with overseas inspection and certification institutions, directly affecting the inspection cycle and the launch plan of products. At the same time, remote information transmission is prone to errors, and the specific requirements of the merchants for the inspection items may be misunderstood, resulting in the issuance of invalid reports, waste of inspection costs, and delay of business opportunities.

The traditional reporting process also exacerbates the efficiency issue. The mailing of paper reports is time-consuming, while electronic reports often require manual processing due to system incompatibility, resulting in communication and document circulation taking up nearly half of the entire inspection cycle.

III. Regulatory Gaps: Core Risks of Incomplete Process Transparency and Difficult Traceability of Responsibilities

During cross-regional inspections, merchants often fail to effectively supervise the inspection and certification processes of off-site institutions. Most institutions only provide final reports, lacking key records such as process videos and original data, making the authenticity of the reports questionable. Existing cases have shown that a few institutions colluded with suppliers, using methods such as selective filming to issue false inspection reports, causing merchants to suffer huge post-sale losses and brand crises.

Even if problems are identified, cross-regional rights protection is extremely difficult. Due to the lack of a unified regulatory coordination mechanism, businesses have to file complaints across different regions. The process is complex, takes a long time, and has a low success rate, leaving the traceability of responsibility for inspection and certification services as a void.

IV. Derivative Effects: Systemic Impact on Supply Chain Stability

The aforementioned uncertainties compelled businesses to allocate a longer inspection buffer period in their supply chain planning, thereby prolonging the overall turnover time. Once any issues are identified during the inspection process, the cross-regional return and exchange logistics as well as the associated time costs will further erode profits and supply chain efficiency. Data shows that cross-regional inspections can significantly reduce the turnover efficiency of the supply chain and increase additional capital occupation costs.

The way to break through in the industry: Establishing a standardized network and a digital supervision system

To systematically address the challenges of cross-regional inspection, factory verification, and certification, the leading practices in the industry point to a model combining a "global standardized inspection network" and a "full-process digital supervision" system.

Establish a unified global inspection and certification network

By setting up operational outlets that comply with international standards (such as ISO/IEC 17020) in major production and sales areas around the world, we ensure that the inspection services in different regions have unified qualifications and execution capabilities. This measure can directly eliminate regional qualification differences, ensure the local recognition of cross-border inspection reports, and minimize the result differences caused by inconsistent standard understanding.

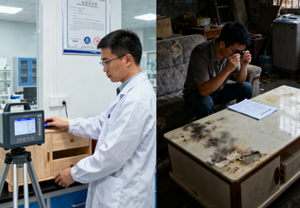

Implement full-process visual inspection and digital evidence storage

By utilizing technologies such as GPS positioning and real-time video live streaming, merchants can remotely supervise the entire process of inspection and factory verification. Inspectors are required to take photos of key steps as per regulations, and all inspection data and videos are uploaded in real time to blockchain and other immutable systems for evidence storage. This completely resolves the issue of process opacity, reduces the risk of false reports to nearly zero, and provides solid evidence for liability tracing.

Promote the digitalization of document circulation and achieve direct connection with the system.

Utilize an electronic reporting system and connect it directly with the merchants' ERP/platform to achieve instantaneous synchronization of inspection reports, eliminating delays caused by paper circulation and format conversion. At the same time, a digital collaboration platform supporting multiple languages can effectively overcome time zone and language barriers, reducing the response time for cross-border communication from several hours to several hours, and significantly shortening the overall inspection cycle.

Share this product

Is cross-regional inspection difficult? Global network + digital super

With the cross-regional and cross-border development of e-commerce, factory verification and certification have become increasingly frequent.