VR Factory Inspection

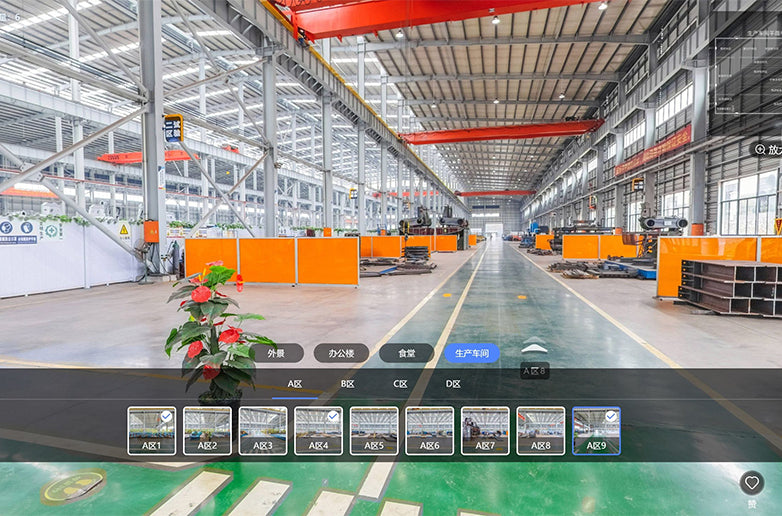

VR panoramic audit service displays the real scene of the factory in 360 degrees, bringing customers an immersive experience. Combined with the professional evaluation of auditors, it effectively controls supply chain risks and promotes business cooperation.

Advantages of VR Panoramic Factory Inspection

1. Panoramic display:

Using high-end equipment for evidence collection, customers can see the overall environment of the factory, including actual production capacity and on-site management status;

2. True reflection:

Cover every corner of the factory, eliminate blind spots, and truly present the health and safety management and control status of the factory site, avoiding the situation in traditional reports that only show the situation of selected local scenes (positive or negative);

3. Professional team:

In the 3D report, real scenes and professional evaluations are used to help customers understand the health and safety risks of the factory site and the advantages and disadvantages of quality management;

4. Cost savings

Without leaving home, you can remotely get 360° information about the actual situation of the factory, saving labor and time costs;

5. Avoid corruption issues:

The display of real scenes and the background evaluation of scenes make it impossible for auditors to evaluate on the spot, thus effectively avoiding corruption problems.

VR factory inspection main process

1. Basic overview and legality risk check

Auditors will understand the basic profile of the factory, including address, area, personnel, equipment, processes, major markets and customers, and production capacity, through on-site visits, interviews with management personnel and document review. They will also focus on understanding its legality risks by checking relevant certificates, such as business licenses, production permits, environmental impact assessments and acceptance, building registration and fire inspections.

2. Establishment and implementation of basic quality management requirements

Auditors will check the establishment and implementation of the factory's most basic quality management requirements, including the implementation of incoming material, process and finished product inspection, change control, defective product control, foreign body contamination risk, measurement facilities and personnel training, to verify whether the factory has the most basic quality assurance in the production process.

3. On-site VR display and evaluation

1) A complete and true 360-degree display of the factory's production layout, processes, facilities, and on-site management. In addition to what the customer can see, combined with the actual scene, the auditor will also make some professional evaluations of the advantages and disadvantages of the on-site production management and quality management to help customers have a clearer understanding of the factory's on-site management capabilities and risks.

2) Auditors also evaluate some basic occupational health and safety management practices on site based on real scenarios, helping clients understand the factory from another dimension.

4. 3D report generation

Through the above process, a real-life report including a 360-degree real-life display and professional evaluation, as well as a PDF report formed by information collection and verification, is formed. The combination of the two reports enables customers to have a more intuitive, in-depth and comprehensive understanding of the factory.

5. Customer feedback and further actions

For the problems found in the audit, the client can ask the factory to implement improvements based on the actual situation. The auditor will supervise the improvements according to the client's requirements, including desktop and on-site follow-up.

VR factory inspection 3D report

According to customer needs, we customize VR factory inspection solutions for customers, and customers can add items according to their own needs; all scenes are shot with advanced and high-end equipment, and the photos and videos are clear and real; finally, we will provide a full set of high-quality audit reports.

Share this product

VR Factory Inspection

A true and in-depth understanding of suppliers is the key to controlling the supply chain. Digital supplier audit services use VR panoramic camera technology to show the supplier's real production scene in 360 degrees without blind spots, plus the auditor's professional evaluation. Customers can intuitively understand their suppliers and ensure that the purchased products are manufactured under good production organization and management and are socially and environmentally friendly.