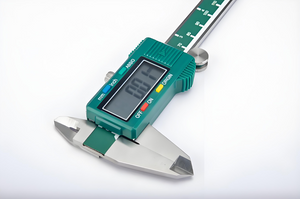

How to inspect goods with a digital caliper? Digital caliper inspection standards

1. Appearance inspection

-

The surface of the ruler and its components must not have any cracks, scratches, bumps, rust, burrs or other defects that may affect the appearance and use.

-

The surface plating or coating shall not fall off or have uneven color that affects the appearance.

-

The scale markings should be clear and complete, without visible broken lines, uneven thickness or other defects that affect the reading.

-

The indicating device (cover, display) must be transparent, clean, and free of scratches, bubbles, and other defects that may affect the reading.

-

The ruler frame and micro-motion device should move smoothly along the ruler body without any sticking or loosening. The brake screw should be able to accurately and reliably fasten the ruler frame to the ruler body.

2. Technical requirements and inspection methods

-

Measuring surface hardness:

-

Use Vickers hardness tester or Rockwell hardness tester to test.

-

On the measuring surface or on the side surface within 2 mm from the measuring surface, take measurements at three points evenly spaced along the length of the measuring surface.

-

The arithmetic mean of the values measured at three points was taken as the result.

-

The hardness of the measuring surface (made of carbon steel, tool steel or stainless steel) should not be lower than the specified value.

-

-

Measuring surface roughness:

-

Use surface roughness comparison blocks for visual comparison or use a surface roughness tester for inspection.

-

The Ra value should not be greater than the specified value.

-

-

External measuring surface flatness and combined clearance:

-

The flatness error of the two external measuring surfaces should not be greater than the specified value.

-

When the two outer measuring surfaces are in contact with each other (regardless of whether the ruler frame is tightened or not), the wide measuring surface should not be transparent and the narrow measuring surface of the blade should not be transparent to white light.

-

-

Maximum allowable error:

-

External measurements: The maximum allowable error should comply with the specified value.

-

Measuring jaw clearance inside the blade: Point the outer jaws of the caliper vertically downward and move the frame to maximize the overlap between the inner jaws. Use a 0.12mm feeler gauge to check; the gap should not be greater than 0.12mm.

-

Depth/step measurement (at 20mm): The maximum allowable error should not exceed the specified value.

-

-

Repeatability:

-

Repeat moving the ruler frame 5 times so that the two outer measuring surfaces touch each other.

-

The maximum difference between the five measured values is the repeatability, which should not be greater than 0.010mm.

-

3. Performance requirements

-

Digital display and response: The display should be clear, complete and flicker-free; the response speed should not be less than 1 m/s.

-

Function keys: The operation should be flexible and reliable; the marking symbols or graphics should be clear and the meaning should be accurate.

-

Digital Drift: After pulling the scale frame to stop at any position and tightening it, observe the change of the displayed value within 1 hour. The drift should not be greater than 1 resolution value.

-

Working current: Use a multimeter or a dedicated chip tester to test, it should not be greater than 40μA.

-

Environmental adaptability: The electronic digital display should be able to operate normally under the conditions of 0°C to 40°C ambient temperature and relative humidity not exceeding 80%.

-

Inspection method (digital display, response, function keys, and drift should be carried out simultaneously): Test and observe whether the function keys function normally, flexibly and reliably; manually move the scale frame to simulate the speed and observe whether the digital display is normal; check the digital drift according to the above method; measure the working current.

4. Communication interface

-

The manufacturer should be able to provide communication cables and communication software that match the digital caliper.

-

The communication cable should be able to convert the caliper output data into RS-232, USB or other universal standard output interface formats.

V. Inspection conditions

-

Inspection environment: Indoor temperature 20°C±5°C, relative humidity not more than 80%.

6. Logo and Packaging

-

Caliper body logo: At least the following should be marked: manufacturer's name or registered trademark, graduation value/resolution, product serial number; stainless steel calipers should have identification marks.

-

Packaging box logo: At least the following should be marked: manufacturer’s name or registered trademark, product name, graduation value/resolution and measuring range.

-

Packaging requirements: The caliper should be treated with anti-rust treatment before packaging and properly packaged to ensure that the product is not damaged during transportation.

-

Certificate of Conformity: Calipers that have been inspected and found to meet the requirements of this standard must be accompanied by a product certificate, which must be marked with the standard number, product serial number and production date of this standard.

Share this product

How to inspect goods with a digital caliper? Digital caliper inspectio

Like vernier calipers and dial calipers, digital calipers are used to measure length, inside and outside diameters, and depth. The caliper body is equipped with a high-precision rack, which rotates a circular grid. Using the principle of photoelectric pulse counting, the displacement of the caliper jaws is converted into a pulse signal, which is then displayed digitally on a screen via a counter and display.