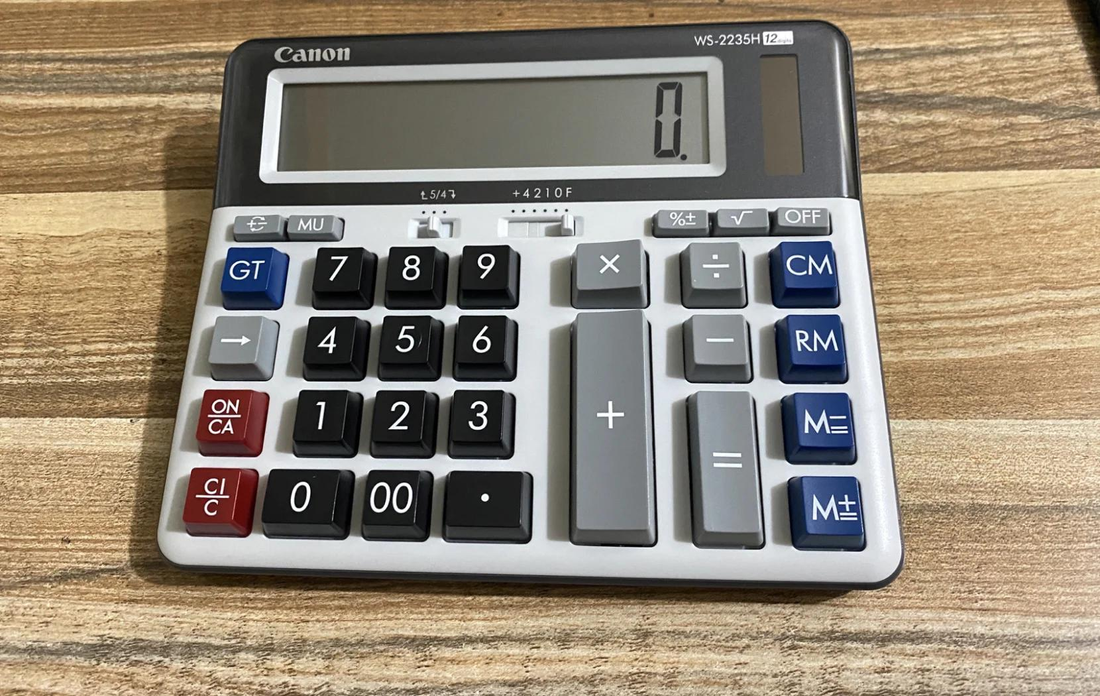

What are the items for calculator inspection? Read on to understand the inspection, factory inspection, inspection and certification services.

Calculator inspection items

As an essential component of our quality control (QC) process, calculator product inspection involves comprehensive checks on packaging, safety, appearance, functionality, and performance. The following detailed inspection specifications, based on industry standards and factory inspection requirements, ensure that products meet customer specifications and quality expectations.

1. Packaging inspection

During the inspection process, packaging inspection is the primary step, which directly affects the storage and transportation safety of products and customer experience. The following contents need to be checked one by one:

-

Outer/Inner Carton Inspection : Check whether the material, printing content, and shipping mark information are consistent with the order requirements, and whether there is any damage, stains, or deformation.

-

Color box/blister packaging inspection : Confirm that the packaging method and design graphics are consistent with the customer's confirmed sample, and whether there is any color difference, inferior material or loose packaging.

-

Accessories inspection : including whether the battery, instruction manual, warranty card, service card, etc. are complete, and whether the model and quantity are consistent with the packing list.

-

Graphic and text consistency verification : The product model, function description, and brand logo on all packaging materials (such as manuals and warranty cards) must be consistent with the actual product.

2. Safety Inspection

During the factory and product inspection process, product safety regulations must be strictly followed to eliminate potential risks:

-

Check the housing and components for sharp edges, corners, and points. If necessary, use RCA paper (scratch resistance test paper) to test the edge strength.

-

Ensure that the product has no risk of small parts falling off, especially in usage scenarios where children may come into contact with it.

3. Appearance Inspection

The first impression of product quality directly affects the inspection results and customer satisfaction:

-

Product conformity inspection : Compare the samples, order requirements, color box patterns, instruction manuals, etc. provided by the customer to ensure consistency in product version, color, and logo.

-

Appearance defect inspection : Check under good light for visible defects such as damage, scratches, paint peeling, stains, poor silk screen printing, etc.

4. Mechanical and structural inspection

This type of inspection is designed to assess the product's assembly quality and structural reliability:

-

Tap test : tap the product to make it vibrate, check whether there is any abnormal noise inside, whether the structure is loose, and rule out poor assembly or the presence of foreign objects.

-

Assembly fit inspection : Check whether the assembly gaps of each part are uniform, whether there is any mis-assembly or missing assembly, and whether the accessories are too loose or too tight.

-

Floor mat flatness test :

-

Place the product on a horizontal glass plate and observe whether it shakes;

-

Use a feeler gauge to measure the gap between the foot pad and the countertop and record the value. If you don't have a feeler gauge, you can use a stack of white paper to estimate the height of the pad.

-

-

Battery box inspection :

-

After installing the battery, close the battery cover and perform a camera test. The product should function normally without interruption.

-

If the customer requires an insulating protective film, its insulation effectiveness must be verified.

-

5. Routine functional inspection

Functional testing is the core step in determining whether a product is qualified and needs to be systematically performed:

-

Power on/off test : Power on and off three times in a row. The product should work normally without any abnormal restart.

-

Dual power supply function test (such as with solar energy) :

-

Remove the battery or disconnect the battery power supply, and test the solar charging function in strong light and dark places respectively;

-

Verify that the rechargeable battery can be charged normally under light conditions.

-

-

Button and function test :

-

Operate all buttons one by one to check whether they respond sensitively and there is no stuck key;

-

Test the automatic shutdown function, record the shutdown time, and conduct parallel testing on multiple machines to improve inspection efficiency.

-

-

Display and storage check :

-

Verify whether the LCD display is missing any dashes and whether the number of digits is consistent with the specifications by calculating "12345679 × 7.2 = 888888888";

-

Confirm that the memory storage function is normal after shutting down.

-

6. Special data and measurement items

This type of inspection focuses on the quantitative evaluation of electrical performance, process and key dimensions:

-

Electrical safety testing : These products generally do not require high voltage safety testing, but must still comply with general electronic product quality regulations.

-

Performance testing :

-

Battery voltage : Use a multimeter to measure the voltage of AA/AAA batteries, which should be ≥ 1.50V;

-

Working/Standby Current : Connect the multimeter in series to the power supply circuit and record the current values in working and standby states;

-

Internal process inspection : If the customer allows, the machine can be disassembled to check the quality of solder joints, component installation and wiring process.

-

-

Size and marking inspection :

-

Barcode scanning : Scan the barcode three times in a row, and all of them must be successfully recognized and consistent with the printed content;

-

Outer box dimensions and weight : Measure and record the length, width, height and gross weight of the outer box and compare them with customer specifications;

-

Product size measurement : If the customer provides dimension specifications, actual measurement is required to confirm compliance.

-

-

Transport simulation test :

-

Carton drop test is performed according to the customer's factory inspection standards or checklist requirements (optional if not required).

-

7. Common defects of calculators

Based on previous inspection experience, special attention should be paid to the following high-frequency quality issues:

-

The buttons are stuck, especially the 'ON/C' button is unresponsive or stuck when pressed in the center;

-

The entire machine has no function and cannot be turned on or used for calculations;

-

The solar panel is damaged or is a decorative piece (false function);

-

The button silk screen is blurred, offset or worn;

-

Corrosion of metal parts;

-

The LCD display has missing strokes, extra strokes, or incomplete display;

-

It is called a solar-powered calculator but is not connected to a real solar panel.

Summarize

Although calculators are common electronic products, their inspection process must strictly adhere to customer standards and inspection specifications, encompassing multiple dimensions such as packaging, mechanics, functionality, and performance. A systematic inspection process not only effectively identifies defects but also promotes improved supply chain quality management, providing reliable assurance for factory audits and customer deliveries. QC personnel are advised to integrate customer checklists and historical defect data during actual inspections to continuously optimize inspection focus and methods.

Share this product

What are the items for calculator inspection? Read on to understand th

As an essential component of our quality control (QC) process, calculator product inspection involves comprehensive checks on packaging, safety, appearance, functionality, and performance. The following detailed inspection specifications, based on industry standards and factory inspection requirements, ensure that products meet customer specifications and quality expectations.