Skipping rope inspection requirements and methods

Rope skipping is a simple and effective aerobic exercise equipment, which consists of a rope body and a handle. It is widely used in fitness, weight loss, competition and children's entertainment. Rope skipping can not only enhance cardiopulmonary function, improve coordination and sensitivity, but also quickly burn fat, exercise lower limb strength and core stability. It is a whole-body exercise suitable for people of all ages. There are many types of modern rope skipping, including ordinary ropes, steel wire ropes, weighted ropes, electronic counting ropes, etc., to meet different training needs. The handles are often made of non-slip materials and feel comfortable to hold. Some rope skipping ropes are also equipped with timing or counting functions to facilitate the grasp of the exercise effect. Rope skipping is easy to carry, takes up little space, and does not require complex venues. It is suitable for home, outdoor or gym use. As an efficient and economical way to exercise, rope skipping has been widely promoted and is an ideal choice for improving physical fitness and health.

Rope skipping classification

According to the structure, it can be divided into:

Skipping rope without handle, skipping rope with handle;

Rope skipping and ropeless skipping.

According to the counting method, it is divided into:

Mechanical counting skipping rope;

Electronic counting skipping rope (including smart skipping rope).

Skipping rope structure

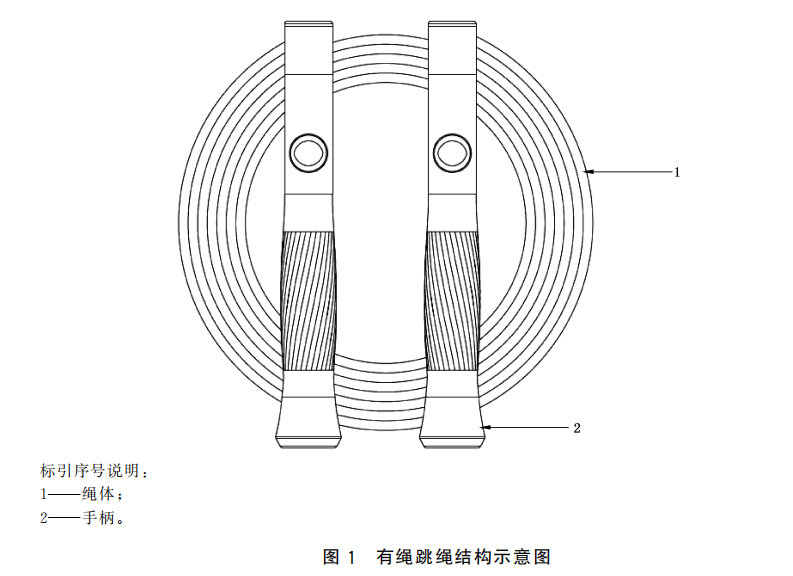

The structure of the rope skipping rope is shown in Figure 1

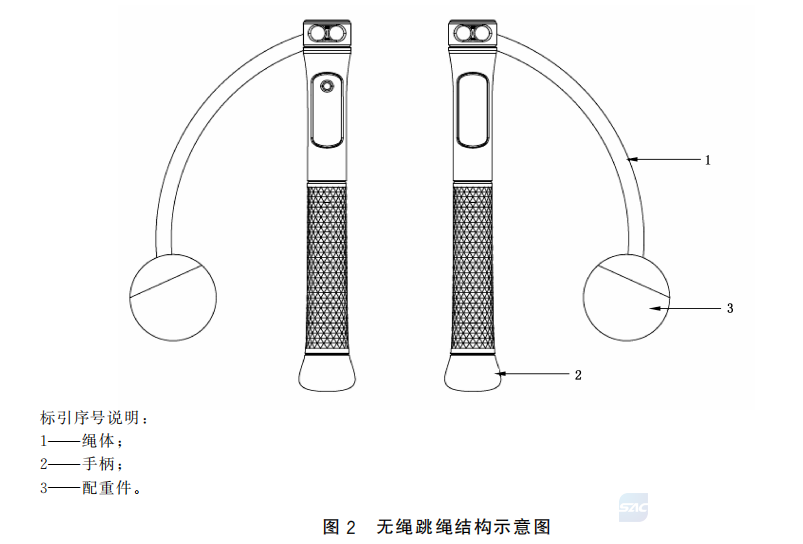

The structure of the ropeless skipping rope is shown in Figure 2.

The structure of the ropeless skipping rope is shown in Figure 2.

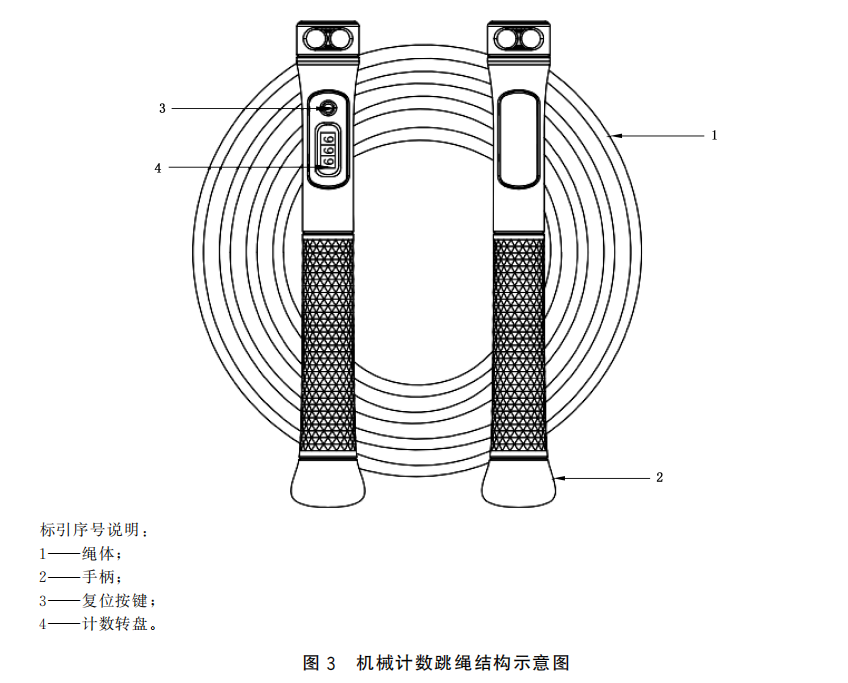

The structure of the mechanical counting skipping rope is shown in Figure 3.

The structure of the mechanical counting skipping rope is shown in Figure 3.

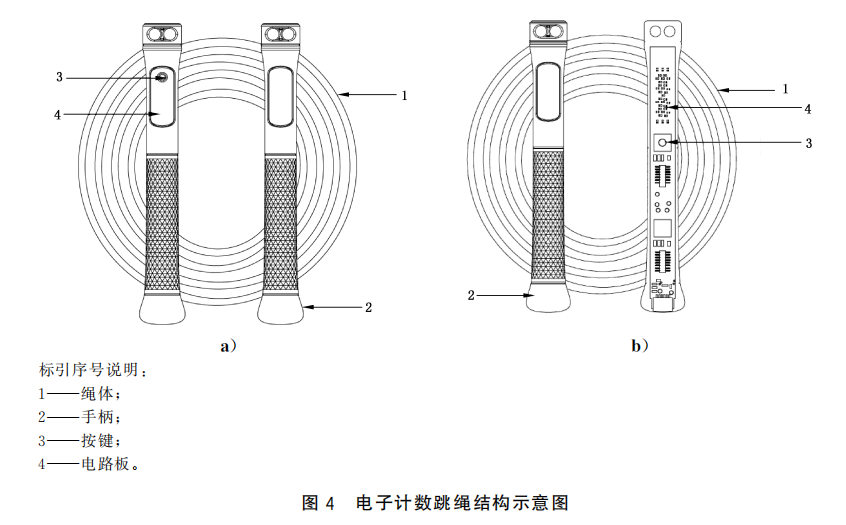

The electronic counting skipping rope structure is shown in FIG. 4 a) and FIG. 4 b).

The electronic counting skipping rope structure is shown in FIG. 4 a) and FIG. 4 b).

Skipping rope inspection requirements

Skipping rope inspection requirements

Basic Requirements

The surface of the weight of a ropeless skipping rope should be soft, and the mass of a single weight should be between 10g and 60g.

The display information of the electronic counting skipping rope should be clear and complete.

The mechanical counting rope skipping buttons should not have obvious sticking, and the electronic counting rope skipping buttons should not have poor contact.

Appearance

The skipping rope should be free of defects such as burrs, cracks, breakage, deformation, and obvious scratches.

Security Requirements

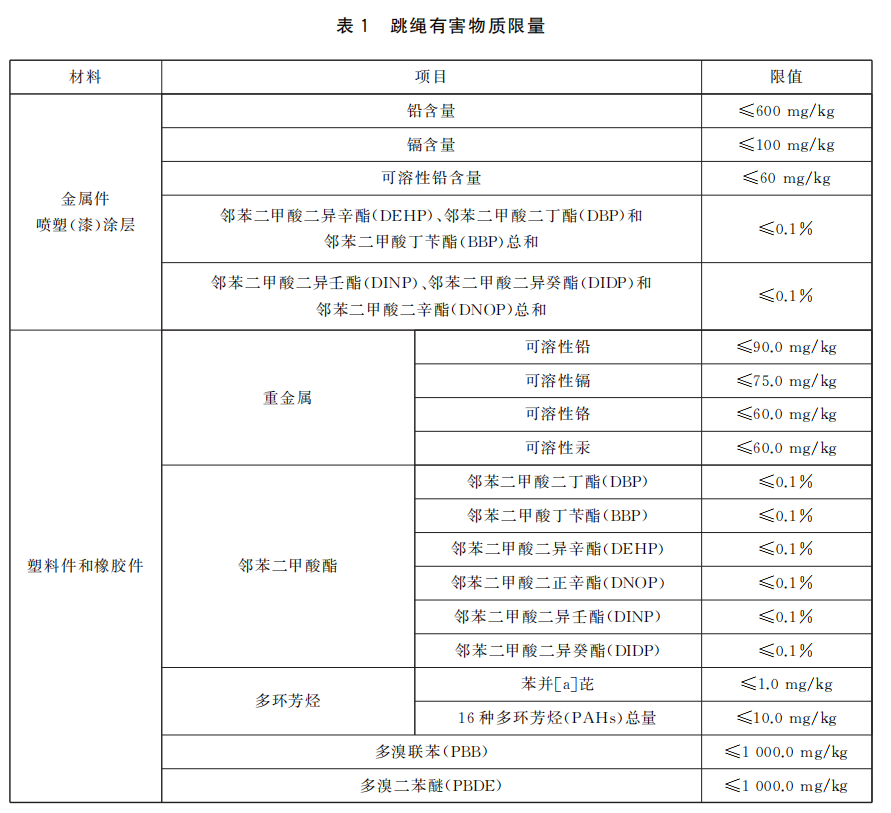

The limits of harmful substances in skipping ropes should comply with the requirements of Table 1.

There is no obvious odor when skipping rope.

There is no obvious odor when skipping rope.

Fatigue

After the 100,000-revolution test, the skipping rope should not break and should be able to be used normally.

Note: Skipping ropes with a rope diameter less than or equal to 3mm are not tested for this item.

The electronic counting skipping rope button should be able to be used normally if it is pressed continuously for 5000 times, and the mechanical counting skipping rope button should be pressed continuously for 2000 times.

Mechanical properties

When a force of (50±2)N is applied in the horizontal direction, the rope skipping handle and the rope fixings should not be deformed, cracked or fall off.

When a force of (100±2)N is applied in the vertical direction, the rope skipping handle and the rope fixings should not be deformed, cracked or fall off.

Note: This item is not tested for ropeless skipping.

After the drop test, the handle of the skipping rope should have no obvious cracks or damage and should be able to be used normally.

For skipping ropes with handles, the rope body and the handle should be firm during use.

high and low temperature

After high and low temperature tests, the skipping rope should not have obvious deformation, rope breakage and other defects.

Counting and timing accuracy

The skipping rope with counting function adopts a rotation speed of 200r/min~400r/min, and the counting error for 1000 consecutive times should be less than or equal to ±1 time.

The 1-minute timing error of a skipping rope with a timing function should be less than or equal to ±1s.

Continuous working time

The continuous working time of electronic counting skipping rope should not be less than 2h

Skipping rope inspection test method

Basic Requirements

The surface of the counterweight is inspected by sensory inspection, and the mass of a single counterweight is weighed using an electronic balance with an accuracy of 0.01g.

The displayed information is visually inspected.

Key test, actual operation.

Appearance

Inspect visually under natural light.

Security Requirements

The limits of hazardous substances shall be inspected in accordance with the provisions of GB6675.4 and GB/T22048.

The odor is tested by sensory inspection.

Fatigue

Fix one end of the handle of the skipping rope and connect the other end of the handle to the motor. The height difference between the two ends of the handle should not exceed ±5cm.

It can rotate smoothly. The handleless skipping rope has fixed ends of the rope.

In a static state, the rope hangs down on the flat cement floor. The rope of a skipping rope contacts the ground for 5cm to 30cm, while the rope of a ropeless skipping rope may not contact the ground.

The friction coefficient of the test ground should be between 0.5 and 0.7.

Start the motor, the motor speed should be greater than or equal to 200r/min.

For cordless skipping ropes, test each handle once.

After the electronic or mechanical skipping rope handle is fixed, press the handle button with a force of 4N. The pressing speed of the electronic skipping rope is greater than or equal to

2 times/S, the pressing speed of the mechanical skipping rope handle is greater than or equal to 1 time/S.

Mechanical properties

Fix the handle horizontally and keep it perpendicular to the rope. Apply tension to the rope for 10 seconds. Test each handle once.

Fix the handle vertically, keep the rope and the handle in a straight line, apply tension to the rope for 10 seconds, and test each handle once.

Remove the skipping rope with handle, turn on the handle, and let it fall freely from a height of 1 m onto the concrete floor twice with the handle parallel to the ground.

Remove the skipping rope with handle, and when the handle is turned on, drop the two ends of the handle freely from a height of 1m to the ground vertically.

For cement floors, do this twice on each end.

high and low temperature

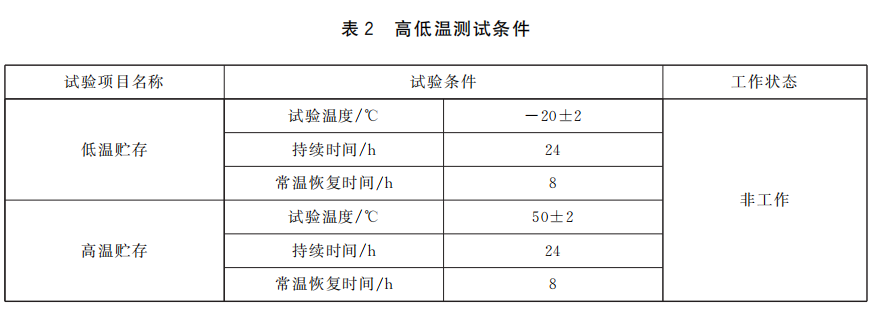

The test conditions in the non-working state shall be carried out as specified in Table 2.

Counting and timing accuracy

Counting and timing accuracy

The skipping rope counting accuracy was measured three times during the 7.4 test, with 1000 consecutive counts each time.

The accuracy of rope skipping timing was tested by using an electronic stopwatch with an accuracy of no more than 0.1 s to test the timing device of the rope skipping for 1 min. The test was repeated 3 times and the average value was taken.

Continuous working time

The test environment is 25℃±2℃, and the test is carried out with fully charged or new batteries.

Start timing after the rope skipping starts, and record the rope skipping working status and test time every 15 minutes.

For skipping ropes with automatic shutdown function, the skipping rope should be restarted within 15 seconds of being shut down.

Share this product

Skipping rope inspection requirements and methods

Rope skipping is a simple and effective aerobic exercise equipment, consisting of a rope body and a handle, which is widely used in fitness, weight loss, competition and children's entertainment. Rope skipping can not only enhance cardiopulmonary function, improve coordination and sensitivity, but also quickly burn fat, exercise lower limb strength and core stability. It is a full-body exercise suitable for people of all ages.