Four-point inspection method for fabric inspection

1. Methods

Under certain lighting conditions, visually inspect and measure defects, score according to predetermined scoring standards, and evaluate the appearance quality of knitted fabrics.

2. Equipment and Tools

1. Fabric inspection machine: The table is at a 45° angle to the vertical line. Six to eight 40W fluorescent lamps are installed in the upper and lower lampshades respectively. The speed of the fabric inspection machine is 16m/min~18m/in, and it is equipped with a length measuring device.

2. Fabric inspection table: The width is greater than the fabric width, the length is longer than 1m, the table surface is flat, and a 40W fluorescent lamp or normal northern light is placed 80cm away from the table surface. 3 Ruler or tape measure: larger than the measurement size, the minimum scale value is 1mm.

4 Color card: GB/T 250 Grey scale for assessing color change.

3. Sampling

Randomly sample 1% to 3% of the delivery batch by type, specification, and color, but not less than 200m. If the delivery batch is less than 200m, the entire batch will be inspected.

IV. Inspection Procedure

1. The fabric moves straight through the visual inspection area to ensure that the visual range is 1m long for inspection

2. Based on the used surface of the fabric, evaluate defects with your eyes at a distance of 70cm to 90cm from the fabric surface.

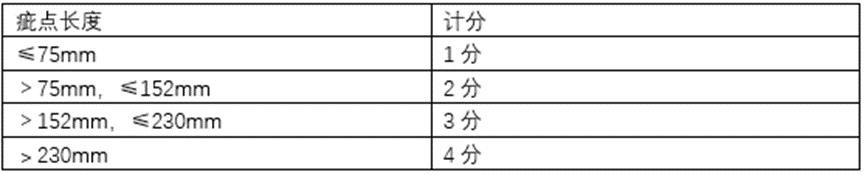

3. Local defects and linear defects are measured by the length of the defects, and strip-shaped defects are measured by the maximum length or maximum width of the defects. The scores are calculated according to Table 1.

Defect scoring regulations

4. Regardless of the size and number of bases, a maximum of 4 points will be awarded for the entire 1m vertical range.

5. Damage defects within 1 meter are scored 4 points regardless of the size of the spot.

6. Obvious scattered defects: 4 points per meter

7. Effective width, deviation exceeds ±2.0%, 4 points per meter

8. Grain skew measurement, vertical limit is 1, horizontal limit is width, exceed 5.0%, each meter is counted as 4 points. If there is a requirement for post-wash distortion measurement, the grain skew can be resolved through negotiation between the supply and demand parties.

9. For color difference assessment with the standard sample, if the color difference is below level 4, 4 points will be awarded for each meter.

10. For color difference assessment of the same piece, if the color difference is lower than level 4-5, 4 points will be awarded for each meter of the whole piece.

11. For color difference evaluation of the same batch, if it is lower than grade 4, 4 points will be given for each meter of the two control pieces.

12. Each seam is worth 4 points.

13. Defects within 30cm from the cloth head will not be scored.

14. The length of each piece of cloth shall be measured by a length measuring device.

5. Result calculation

The total score of each piece of cloth is calculated per 100 square meters or per 100 meters (full width). The calculation formula is shown in formula (1) and formula (2).

(1) R1=10000*P/(W*L)

(2) R2=100P/L

R1——Average score per square meter of cloth

R2——average score per 100 meters of cloth

P——Total score of each piece of cloth

W——actual effective width, in centimeters (cm)

L——actual length, in meters (m)

Note: The result is rounded to an integer.

Share this product

Four-point inspection method for fabric inspection

The "four-point system" is the most common method used for on-site inspections of fabrics. The four-point system assigns a maximum of four points to a defect within a 1-meter vertical width, regardless of its size or number.