Inspection and Testing | New Version of ISO Clothing Label Standards Released

A Guide to Care Label Inspection and Final Random Inspection in Textile & Apparel Production

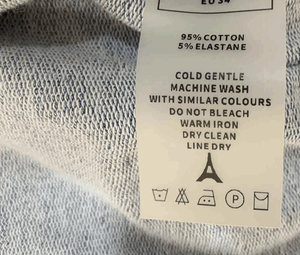

Care label inspection is an indispensable component of the Final Random Inspection (FRI) conducted by third-party quality control companies in textile and apparel manufacturing. The recent release of the updated international standard, ISO 3758:2023, introduces key changes that inspectors and suppliers must implement.

🔄 Key Updates in ISO 3758:2023 for Care Labeling

The fourth edition of the standard, which replaces ISO 3758:2012, includes several important revisions relevant to production inspection and compliance verification:

-

Expanded Exemptions: The new standard specifies three product categories exempt from requiring a care label when professional cleaning technology is needed:

-

Upholstery textiles that are not permanently attached to furniture.

-

Mattress covers that are not permanently attached.

-

Carpets and rugs intended for cleaning by specialists.

-

-

Revised and New Care Symbols:

-

Hand Wash Symbol: The existing symbol is updated, and a new symbol for hand washing at ambient temperature is introduced.

-

New "Do Not Steam" Ironing Symbol: A dedicated symbol is added to indicate garments that should not be steamed.

-

"Do Not" Symbols Revised: The symbols for Do Not Wash, Do Not Bleach, and Do Not Iron have been modified from the 2012 version.

-

Dry Cleaning Symbols: The graphical symbols remain unchanged, but the accompanying textual descriptors have been updated.

-

ISO 3758 establishes a system of symbols for marking textiles, providing information on the most severe treatment that will not cause irreversible damage during care.

✅ Textile & Apparel Final Random Inspection: Scope & Methodology

A comprehensive FRI, typically performed when at least 80% of the order is packed, is crucial for verifying overall quality, workmanship, and compliance before shipment. The inspection is based on statistical sampling (often following AQL standards) and covers the following key areas:

1. Packaging & Documentation Check

-

Verifying outer shipping marks, polybags, barcode stickers, hangtags, and hangers against purchase orders and client specifications.

-

Inspecting packing assortment, carton quantities, and size ratios for accuracy.

2. Product Conformance & Workmanship Check

-

Visual Inspection: Checking garments for defects such as stains, holes, pulls, yarn variations, color fading, shading, or other visible flaws.

-

Measurement / Dimension Inspection: Measuring all critical garment points (e.g., chest, waist, length, sleeve) against approved tech packs or size specs to ensure they fall within tolerance limits.

-

Fabric Inspection: Identifying fabric-related issues like slubs, knots, holes, missing yarns, color streaks, or side-center-side shading.

-

Accessories & Trims Inspection:

-

Zippers: Functionality, smooth operation, correct type, and safe finishing.

-

Buttons/Snaps: Secure attachment, correct color/size, and non-sharp edges.

-

Sewing Thread: Correct color, specification, and colorfastness.

-

-

Construction & Stitching Inspection: Assessing the symmetry of collars, sleeves, pockets; the evenness of seams; the proper attachment of zippers; and the overall integrity of stitching.

-

Finishing & Pressing Inspection: Evaluating the final garment for smooth pressing, absence of undesirable shine, wrinkles, water marks, or discoloration.

📋 Integrated Quality Control Services for Textiles

Professional third-party inspection providers support brands and importers through various stages of production to mitigate risks:

-

Initial Production Check (IPC): An early factory audit of components, materials, and initial output to identify issues before mass production.

-

During Production Check (DPC) / Mid-Line Inspection: An inspection performed when 20-50% of units are completed to check quality and consistency, allowing for timely corrections.

-

Final Random Inspection (FRI) / Pre-Shipment Inspection: The definitive verification of finished, packed goods as detailed above.

-

In-Line Quality Monitoring: Continuous on-site presence of an inspector for high-volume or complex orders.

-

Container Loading Supervision: Oversight of the loading process to ensure correct carton counts, prevent damage, and verify proper loading procedures.

By integrating these inspection and verification steps—particularly ensuring care labels comply with the latest ISO 3758:2023 certification requirements—businesses can effectively control quality, ensure regulatory compliance, and protect brand reputation throughout the supply chain.

Share this product

Inspection and Testing | New Version of ISO Clothing Label Standards R

A Guide to Care Label Inspection and Final Random Inspection in Textile & Apparel Production