Inspection standards and inspection methods for mobile phone data cables Inspection and factory inspection services

The mobile phone data cable, as the most frequently used digital accessory in daily life, its quality directly affects the user experience and the safety of the device. The quality inspection of data cables is a systematic project, involving the entire process quality control from raw material entry to finished product exit. This article will deeply analyze the factory inspection and inspection process of data cables, the key points of quality control and the testing standards, providing a comprehensive reference guide for purchasers, quality inspectors and manufacturers.

I. Basic Knowledge of Data Cables and Pre-Inspection Preparation

(1) Technical Characteristics and Classification of Data Cables

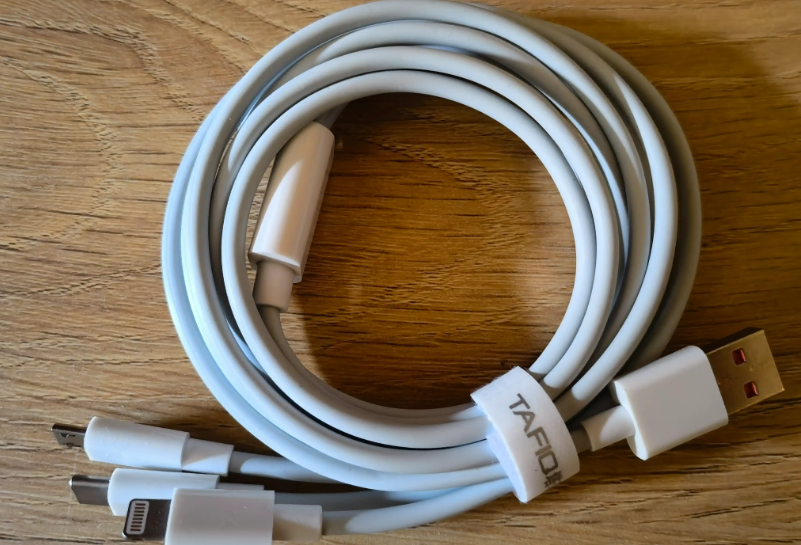

Data cables are electronic accessories that enable data transmission and device charging through wired connections. Their core technologies include wire conductors, shielding layers, interface terminals, and chip identification modules. According to interface types, they are mainly classified as Type-C, Lightning, Micro USB, etc. According to functions, they can be divided into charging cables, data cables, fast charging cables, and other different types.

(2) Preparation for Factory Inspection and Goods Inspection

Technical document review: Check product specifications, USB-IF certification, MFi certification (Apple certification), wire UL certification, RoHS test report, REACH compliance statement

Verification standard confirmation: Clearly define the applicable national standards (GB/T related standards) and the customer's specific requirements, including electrical performance standards, mechanical performance standards, and environmental adaptability standards.

Calibration of testing equipment: Ensure that devices such as network analyzers, DC resistance testers, plug-in and pull-out life testers, insulation resistance testers, and voltage withstand testers are within their calibration validity period.

Sampling plan determination: Based on the batch size, determine the sampling quantity and acceptance criteria in accordance with GB/T 2828.1-2003, and formulate the sampling inspection plan.

II. Key Points for Data Cable Factory Audit

(1) Quality Management System Audit

Check whether the factory has established a complete quality management system (ISO9001 certification), and review the quality manual, procedure documents, and operation instructions.

Review the supplier management procedures, especially the evaluation records of key component suppliers such as wire materials, interface terminals, and chips, including supplier qualification certifications and incoming material inspection standards.

Review the production process control documents and their implementation status, with a particular focus on the control of process parameters for key procedures such as welding techniques, injection molding, and final product testing.

Evaluate the effectiveness of the control procedures for non-conforming products and the corrective and preventive measures, including the processes of marking, isolation, review and disposal of non-conforming products.

(2) Key points of on-site production inspection

Incoming material inspection area: Review the inspection records of key components (copper wires, rubber compounds, terminals, chips), and confirm the implementation of the IQC inspection standards

Welding Workshop: Evaluate welding temperature, duration, and quality control of weld points, inspect the glossiness of weld points, and identify cases of poor welding or false welding.

Injection Molding Workshop: Verify the control of injection molding process parameters and the maintenance records of molds, and confirm that the injection molded parts have no shrinkage, burrs, or other defects.

Test station: Verify the execution status of all inspection items, as well as the completeness of test records, including conduction tests, functional tests, and appearance inspections.

Aging test area: Check whether the aging time and test items meet the process requirements, and evaluate the product durability test standards.

III. Data Cable Inspection Environment and Sampling Standards

(1) Inspection Environment Standards

Visual inspection conditions:

Observation distance: 250mm - 350mm

Testing time: 5 to 10 seconds per side

Observation angle: 45° from the tabletop, adjustable by 15°

Light source requirements: D65-CLE standard light source, illuminance 1000 ± 200 LUX

Environmental parameters:

Temperature: 23 ± 3℃

Humidity: 30% - 85%

Inspector's vision: 1.0 or above (including corrected vision)

Inspecting surface: Made of acrylic or frosted glass, without reflective surface.

(2) Sampling Inspection Plan

Sampling standard: Based on GB/T 2828.1-2003 General Inspection Level II, formulate the sampling inspection plan

AQL standard:

Serious defect: AQL = 0.65

Main defect: AQL = 1.5

Secondary defect: AQL = 4.0

Sampling batch management: Ensure sampling representativeness. Sample different production batches separately.

IV. Appearance Quality Inspection Standards

(1) Shell Quality Inspection

Structural Integrity:

No cracking, deformation or scratches.

No shrinkage, stains or frayed edges.

The color is uniform and there is no color difference.

The surface treatment is uniform and flawless.

Interface Quality:

The terminals are not oxidized or rusted.

The insertion and removal force is moderate.

The identification is clear and correct.

The coating is uniform and there is no peeling off.

(2) Inspection of Wire Quality

Appearance of the wire:

No burns, no damages, no deformations

The wire diameter meets the specification requirements.

The covering layer is uniform and flawless.

There are no cracks at the reinforcement area of the net tail.

Nameplate marking:

The pasting position is correct and flat.

No missing stickers, no upside-down stickers, no raised stickers

The information is accurate and clear.

Durability meets the requirements.

V. Electrical Performance Testing

(1) Basic Function Testing

Charging Function Testing:

Carry out charging tests using the adapter connection

The charging current is in accordance with the nominal value.

Non-contact malfunctions

Fast charging protocol compatibility

Data transmission test:

File transfer rate test

Connection stability test

Compatibility testing

Transmission bit error rate detection

(2) Electrical Parameter Testing

Voltage Drop Test:

Testing under full load conditions

The pressure drop meets the standard requirements.

Stability under different load conditions

Conduction resistance test:

Test using a micro-ohmmeter

The resistance value is within the allowable range.

Contact resistance stability

Insulation resistance test:

Test the insulation performance of the wire material

Compliant with the safety regulations standards requirements

Passability of pressure resistance test

VI. Reliability Testing Items

(1) Mechanical Reliability Testing

Insertion and Ejection Life Test:

Number of tests: 5000 - 10000 times

The function is normal after the test.

Evaluation of interface wear degree

Bending test:

Make 5,000 left turns and 5,000 right turns respectively.

No circuit break occurred after the test.

Inspection of the integrity of the outer coating of the wire material

Swing test:

Load 200g, swing left and right by 45°

Number of tests: 5000 times

Verification of connection stability

(2) Environmental Adaptability Testing

High and Low Temperature Test:

High temperature: Functions normally in an environment of 55℃

Low temperature: Functions normally in an environment of -10℃

Temperature cycling test

Hydrothermal test:

Tested under a temperature of 40℃ and a humidity of 93%

The insulation performance after the test meets the requirements.

Corrosion resistance of metal components

VII. Analysis and Control of Common Defects

(1) Severe Defects

Functional Failure:

No charging, no data transmission

Identifying chip failure

Poor contact of the interface

Safety hazards:

Insulation damage

Short-circuit phenomenon

Risk of overheating

(2) Main Defects

Appearance Issues:

Obvious scratches and deformation

Severe color difference

Structural defect

Poor performance:

Charging speed is too slow.

The transmission rate does not meet the standard.

Compatibility issues

(3) Minor Defects

Appearance defects:

Minor scratch

The sign is slightly tilted.

Slight color difference

VIII. Packaging Inspection Standards

(1) Packaging Material Inspection

Inner Packaging:

The packaging materials meet environmental protection requirements.

Seismic protection measures are in place.

Packaging integrity inspection

Outer packaging:

The strength of the carton meets the transportation requirements.

The identification is clear and accurate.

Stacking test passed

(2) Identification Information Verification

Product Information:

Specification model and material code are accurate.

Production date and batch number are correct.

Certification mark is complete.

Supplier Information:

Qualified Supplier Identification

PASS label or seal is intact

The information is traceable and clear.

(III) Special Requirements

Change Identifier:

The materials for the change must be specially marked in three consecutive batches.

Carry out special packaging in accordance with communication requirements

Compliance of the change control process

Protection Requirements:

The foam pad provides adequate protection.

Special requirements shall be implemented in accordance with the written notice.

Anti-static packaging requirements

IX. Quality Document Requirements

(1) Inspection Reports

Shipping Inspection Report:

Including both full inspection items and sampling inspection items

The data is true and complete.

Inspector has signed and approved completely.

Reliability Test Report:

Including the results of all reliability tests

Complies with the product specification requirements

Test environment records are complete.

(II) Certification Documents

Product Certification:

USB-IF Certification Certificate

MFi Certification Certificate (if applicable)

Quality System Certification Certificate

Security Certification:

UL Certification Certificate

CE certification certificate

Certification certificates from other regions

X. Conclusion

The quality inspection of data cables is a multi-dimensional systematic project involving electrical performance, mechanical structure, material durability, and safety reliability. Quality inspection personnel need to have a comprehensive understanding of product standards, inspection methods, and common quality issues in order to effectively control product quality. Manufacturing enterprises should establish a complete quality management system, especially strengthening control in aspects such as raw material control, process optimization, and product inspection, to ensure that the products meet national standards and customer requirements.

Share this product

Inspection standards and inspection methods for mobile phone data cabl

Data cables, as the most frequently used digital accessory in daily life, their quality directly affects the user experience and the safety of the devices.