Blog Posts

Household Appliance Inspection | Electric Shaver Inspection Standards and Methods

Electric shavers are a convenient and modern shaving tool that is widely used in men's daily lives, providing an efficient and comfortable shaving experience. Compared with traditional manual shavers, electric shavers are easy to operate and do not require shaving foam or water, making them particularly suitable for a fast-paced lifestyle. The quality of an electric shaver directly affects its performance, service life, and user experience.

What is COC certification? Which countries need COC certification? How to apply for it?

COC certification (Certificate of Conformity) is an official document that proves that a product complies with the technical standards, regulations and quality requirements of the importing country. This certification ensures that the exported products meet the safety, environmental protection and performance standards of the target market and is one of the necessary documents for customs clearance in many countries.

What is SMETA certification? What is SEDEX certification? How much does it cost? What are the requirements?

SMETA (Sedex Members Ethical Trade Audit) is a widely used social responsibility audit method. Its core purpose is to ensure that suppliers comply with ethical trade, social responsibility and sustainable development standards in their business activities.

Tableware Inspection | Paper Cup Inspection Standards and Methods

Paper cups are disposable containers, usually used to hold drinks or food, and are widely used in parties, catering, take-outs, and other occasions. Its main raw material is paper, and there is often a thin coating on the outside, such as wax or plastic, to prevent liquid from penetrating and softening the paper. Paper cups are widely popular because of their lightness, cheapness, and convenience.

What is Higg FEM certification? What is the process of Higg FEM certification? What is the cost of Higg FEM certification?

Higg FEM is a tool launched by the Sustainable Apparel Coalition (SAC) to evaluate the environmental performance of textile, apparel and footwear manufacturing factories. Its full name is Higg Facility Environmental Module.

Fabric Inspection | Methods for Defect Inspection on Printed and Dyed Fabrics

Printed and dyed fabric refers to textile fabric that has been processed by printing, dyeing and other processes. It is usually woven into grey fabric first, and then given patterns or colors through printing and dyeing technology. When inspecting printed and dyed fabric, how should its surface defects be inspected?

Tableware Inspection | Pulp Molded Tableware Inspection Standards and Methods

Pulp molded tableware is paper tableware made from pulp through processes such as forming, molding, and drying. It is used for take-out and dine-in containers in take-out, restaurants, coffee shops, and fast food restaurants, such as disposable plates, bowls, cups, lunch boxes, etc. It can also be used for the packaging of fresh and semi-finished foods, such as fruit trays, egg trays, lunch boxes, etc.

What does foreign trade factory inspection mean? Is it necessary? What are the types? What is the process?

Foreign trade factory inspection refers to an audit conducted by an external audit agency on the factory's production environment, quality control, social responsibility, environmental protection, etc. in order to meet the requirements of international trading partners. Its main purpose is to ensure that the supplier's production capacity, compliance and product quality meet the requirements of international buyers or brands.

What is full inspection? What is the process and method of full inspection?

Full inspection, also known as full inspection (100% inspection), is a quality control method that inspects and checks the quality of each product one by one after the production is completed. Different from the sampling inspection that only selects part of the products for inspection, the key to full inspection lies in comprehensiveness, that is, not missing any product, so as to ensure that each product meets the design and quality standards.

Clothing Inspection | Tie Inspection Requirements and Methods

A tie is a decorative clothing accessory that is usually worn with formal attire such as shirts and suits. It is a long, thin piece of cloth, usually made of silk, cotton, wool or synthetic fibers, tied at the base of the neck. Ties not only play an important role in the workplace and formal occasions, but can also express personal style.

What is AQL sampling inspection?

AQL sampling inspection is mainly used in large-scale production. By sampling a part of a batch of products, it is inferred whether the quality of the entire batch of products meets the requirements. The core idea of the AQL sampling method is that it is not necessary to inspect every product, but to estimate the quality level of the entire batch by sampling a part of the products, thereby saving cost and time.

Manual wheelchair inspection

A manual wheelchair is a common device that helps people with limited mobility (such as the elderly, disabled people, or patients undergoing rehabilitation) to achieve daily mobility. It usually consists of a lightweight frame, two large rear wheels, two small front wheels, a seat, a backrest, pedals, etc. A manual wheelchair is mainly driven by the user himself or by others, and is often used for short-distance activities indoors and outdoors.

Paper lunch box inspection

Paper lunch boxes are an environmentally friendly food packaging container, usually made of food-grade paper, kraft paper or coated paper. They can be used once or recycled using degradable materials as needed. Paper lunch boxes are widely used in takeout, fast food, bento and various food packaging, and are the preferred alternative to plastic lunch boxes.

Inflatable Toy Inspection

Inflatable toys refer to toys made of latex or plastic (such as soft polyvinyl chloride film) and filled with air, nitrogen or inert gas, including toys for children to play with that are already inflated or pre-inflated. Such toys generally include balloons for children to play with, inflatable sports imitation toys (such as ball toys), inflatable modeling toys, inflatable carrying toys (such as inflatable furniture toys), etc.

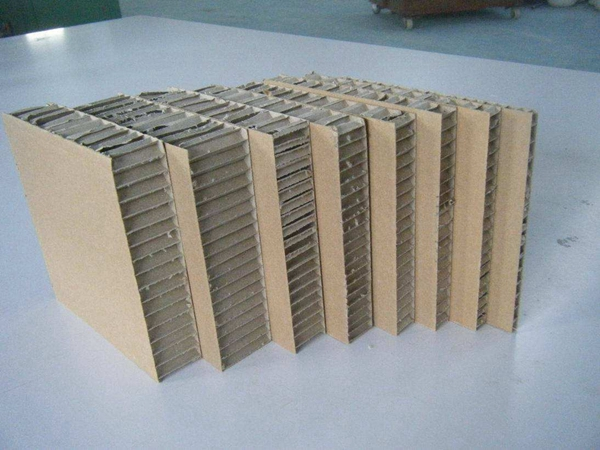

Honeycomb cardboard box inspection requirements and methods

Honeycomb paperboard boxes are packaging boxes made of paper materials with a honeycomb structure. Its design is inspired by the hexagonal structure of the honeycomb. This honeycomb structure provides excellent strength and support while reducing the use of materials, making honeycomb paperboard boxes light and environmentally friendly. They are widely used in industrial packaging, home appliance packaging, agricultural products and food packaging, e-commerce express packaging and other logistics and warehousing fields.

Kitchenware product inspection

There are many types of kitchen knives, including chef knives, paring knives, slicing knives, serrated knives and multi-purpose knives, each designed for different purposes. High-quality knives are usually made of high-carbon stainless steel, which is sharp, durable and corrosion-resistant, and the handles are ergonomically designed to provide a comfortable grip and stable operation.

What is PVOC certification?

PVOC is a compliance certification for product exports, ensuring that products entering a specific country meet local quality, safety and environmental standards. This certification is mainly carried out before the goods are shipped to prevent substandard goods from entering the market. PVOC certification is usually carried out by a designated third-party organization and provides exporters with the necessary compliance certificates.

What is BSCI factory audit?

BSCI factory audit means that enterprises follow the social responsibility code of conduct established by the "Global Trade Association amfori" and pass the assessment of the auditing agency to ensure that the production conditions of their supply chain meet the international social responsibility standards. This system focuses on labor conditions, employee rights, environmental protection and business ethics, and aims to improve the transparency and responsibility of the working environment in the supply chain.

Children's umbrella inspection requirements and methods

Children's umbrellas are small umbrellas designed for children, focusing on safety, lightness and fun. The umbrellas are usually made of environmentally friendly and non-toxic materials, with bright colors, cartoon patterns or cute designs, and are loved by children. The ribs are generally made of fiber or plastic, which is light and has no sharp edges, reducing safety hazards during use.

Baby cradle inspection method

A baby cradle is a small sleeping device designed for newborns to provide a safe and comfortable sleeping environment. Its structure usually includes a stable frame, a soft mattress and a protective fence. Some are also equipped with rocking functions, soothing music and sunshade designs to simulate the mother's arms, help babies fall asleep and soothe their emotions.

Let you know about Kuwait KUCAS certification (TIR/TER COC certificate)

KUCAS (Kuwait Conformity Assurance Scheme) is a mandatory conformity assessment system implemented by the Public Authority for Industry (PAI) of Kuwait to ensure that imported products comply with Kuwait's national standards and technical regulations to protect consumer safety and national interests.

Introduction to Thailand's key industries, foreign trade, import and export regulations, and investment regulations

Thailand is located in the center of ASEAN, with obvious location advantages, a relatively stable society, high policy transparency and trade liberalization, and an open and inclusive business environment. In 2023, Thailand's GDP exceeded US$500 billion, making it the second largest economy in ASEAN. Thai goods enjoy zero tariff treatment in ASEAN countries, and have a strong radiation capacity to neighboring countries.

Let you know about C-TPAT anti-terrorism factory inspection

Why do we need C-TPAT: After the 9/11 incident, CBP hopes to cooperate with relevant industries to establish a supply chain security management system to ensure the transportation safety, security information and cargo status of the supply chain from the starting point to the end point, and ultimately prevent terrorists.

What is First Article Inspection (FAI)? What is the process of First Article Inspection?

First Article Inspection is also known as "initial quality control." It is a check and comparison between product design requirements (specifications) and final production results. During the First Article Inspection process, samples from the first product or first batch of parts produced using a new method are thoroughly tested. The supplier usually performs the First Article Inspection, and the customer (such as you) is responsible for evaluating the inspection report.

Requirements and methods for inspection of fountain pens

A fountain pen, also known as a fountain pen, is a writing instrument that delivers liquid ink to the tip of the pen through an internal ink storage system. Its design combines gravity and capillary action to make writing smooth and easy. The fountain pen originated in the Islamic world in the 10th century, and the early prototype was a simple ink storage device.

6 key steps to follow during container loading supervision

In order to avoid unknown problems when loading goods into 40' or 20' containers or transporting them in less than container load (LCL), buyers usually choose container loading supervision (CLS) . This is an effective solution for importers to ensure that the loading process meets the contract requirements and the packaging complies with the provisions of the purchase contract.

Fully inspected in China

Have you ever found that even after sampling your shipments, you still found defective products? If so, you need to conduct a full inspection . Choosing a full inspection service means you don't have to worry about product quality . Poor quality products can result in refunds, additional taxes, and even expensive recalls or legal action .

Mid-production inspection DPI/DUPRO

During Production Inspection (DPI), also known as "in-process inspection" or "DUPRO inspection", is a vital part of the quality assurance process in the manufacturing industry. It helps identify defects or deviations from preset standards by systematically evaluating products, components or materials at various stages of production.

What does the inspection standard AQL 2.5 mean?

AQL stands for Acceptance Quality Limit, which refers to the maximum number of defects allowed in a batch of products agreed upon by the buyer and seller. Importers can set different levels of AQL standards, including fatal defects, major defects and minor defects.

Camping tent inspection requirements and methods

Camping tent is a portable shelter designed for outdoor adventure and leisure. It uses high-strength waterproof fabric and wear-resistant aluminum alloy bracket, which can remain stable in wind, rain and harsh weather conditions. The interior layout of the tent is reasonable and spacious, which is suitable for family camping, single hiking and team outdoor activities.

What is Final Production Inspection (FRI)? What is the importance of Final Production Inspection?

Final Random Inspection , also known as Pre-shipment Inspection (PSI inspection), is part of supply chain management and an important quality control method for customers to check the quality of goods purchased from suppliers.

What is the process of random sampling inspection?

If you’re outsourcing from overseas, you’re likely relying on a network of different suppliers, each with their own processes and quality controls. While some suppliers will consistently provide a high-quality product, others may require more stringent oversight.

What is G-Mark certification? Which products need G-Mark certification? Detailed explanation of G-Mark certification process

The G-Mark (Gulf Mark of Conformity) is a certificate of conformity that indicates that a product has been tested and meets the quality and safety standards set by the Gulf Cooperation Council (GCC) member countries. The mark is applicable to a wide range of products sold in GCC member countries, including Bahrain, Kuwait, Oman, Qatar, Saudi Arabia and the UAE.

Initial production inspection IPC/IPI

Initial Production Inspection is a quality control measure that systematically checks goods and materials at the beginning of the production process. An Initial Production Inspection (IPI) is performed by an impartial third-party inspector to assess the supplier's ability to meet the buyer's quality requirements and identify production risks that may lead to defects or non-compliance.

Home Textile Product Inspection

Towels are a type of fabric used for wiping and cleaning, and are widely used in personal care, household life, and the hotel industry. They are generally made of cotton, bamboo fiber, or microfiber, have good water absorption and softness, and can be used to wipe the face, body, and furniture surfaces. High-quality towels are soft to the touch, absorb water quickly, are durable, and are not easy to shed, which can effectively help keep the skin dry and clean.

Household appliances inspection

Electric rice cookers should focus on safety performance and be equipped with protection devices such as anti-dry burning and automatic power off to effectively prevent kitchen accidents. Whether it is a fast-paced urban life or a leisurely family gathering, electric rice cookers have become an indispensable and important appliance in modern kitchens with their intelligent, practical and energy-saving features.

Why QC Professionals Choose AQL Sampling for Product Inspection

They needed to ensure the reliability of ammunition in the field, but they didn’t want to over-test the ammunition to the point where it was unavailable. Their solution was to develop the MIL-STD-105 standard, which is based on the concept of acceptable quality limit (AQL) . Among other sampling standards that followed, ANSI ASQ Z1.4 is the most widely used specification by inspectors today.

10 AQL Terms Importers Must Know

If you are like most importers, you have probably struggled with these questions at some stage. When order sizes run into the hundreds or even thousands of pieces, you need a way to reliably assess product quality without having to visit the supplier’s factory. This is where the Acceptable Quality Level (AQL) comes in.

What are the categories of quality defects? How to judge?

You produce women's shirts in Indonesia, and a third-party inspection report shows that about one-third of the shirts have untrimmed threads. Would you classify this as a "minor" or "major" defect? You might consider untrimmed threads a "minor" defect that does not affect the saleability of the product, but if the product is sold to high-end retailers with lower quality tolerance, it might be considered a "major" defect.

A Guide to Quality Control for Startups

The first step to maintaining product quality is to establish clear standards. These standards act as a blueprint to ensure that everyone on the team understands quality expectations. By defining specific benchmarks, startups can measure their performance and identify areas for improvement. It is important to balance setting high goals with being realistic, and to review and update standards regularly to adapt to market changes.

Minimize cargo transportation risks

Are you concerned about the safety and compliance of your cargo during transport? Don’t take any chances! Book our container loading inspection service now to minimize the risk of cargo damage or loss during transport. Our experienced inspectors will verify and ensure that your products are loaded safely and in compliance with all relevant regulations.

Pet Product Quality Control

Owning a pet is a rewarding journey that can significantly improve the owner's quality of life. The companionship and emotional support provided by pets can help reduce stress and enhance happiness. Many pet owners promote their health through activities such as walking their dogs and interacting with their pets. This trend has driven the booming pet products industry, with a variety of products that meet the needs of pets emerging on the market.

Detailed explanation of third-party inspection related inspections

In international trade and manufacturing, third-party inspection plays a vital role. Especially in the global supply chain, the geographical distance between manufacturers, suppliers and customers makes quality control more complicated.

Stationery Inspection

A pencil is a common writing and drawing tool, mainly composed of a graphite core and a shell. The graphite core is made of a mixture of graphite and clay, and the hardness and color depth (such as 2B, HB, etc.) can be changed by adjusting the ratio. The shell is traditionally made of wood, but there are also alternatives made of plastic or environmentally friendly materials.

The global standard for apparel quality control

The apparel industry is one of the most diverse and globally connected, with manufacturers, designers and retailers operating across borders to meet consumer demand. However, this global presence also means that maintaining product consistency and quality across different markets can be a major challenge.

Paper towel inspection

The production process of paper towels must comply with national hygiene standards. Some high-end products also have environmental protection functions such as antibacterial, dust-free, and biodegradable. With various packaging forms, it is easy to carry and use, and is an indispensable cleaning product in modern people's lives. As consumers' awareness of health and environmental protection increases, high-quality, natural, and safe paper towel products are becoming increasingly popular.

A complete analysis of Mexico’s NOM certification

If you’re looking to sell products in Mexico, you’ve probably come across the term “NOM certification.” But what exactly is it? And why is it so important? In this comprehensive guide, we’ll explore NOM certification, breaking down its purpose, process, and everything you need to know to successfully navigate Mexico’s quality control standards.

Key points of quality control for pre-shipment inspection

Pre-shipment Inspection (PSI) As a key link in supply chain quality control, it is responsible for ensuring that products meet quality standards, regulatory requirements and customer expectations. However, in actual operations, a series of potential pitfalls may lead to a loss of inspection effectiveness, and even cause quality risks, compliance risks and customer trust crises.