Blog Posts

Introduction to Badminton Inspection Methods and Testing Standards Inspection and Audit Services for Warehousing and Factory Verification

As professional sports equipment, the quality of badminton is directly related to the performance of the athletes and the fairness of the competitions.

The inspection methods and testing standards for mice and keyboards

The keyboard and mouse, as the most important input devices of a computer, their quality directly affects the user experience and work efficiency.

The inspection and testing standards for DSLR cameras and the experience in testing them

As sophisticated optical and electronic devices, the quality of DSLR cameras directly affects the imaging effect and user experience.

Introduction to Inspection and Testing Standards for Ceramic Basin Ware Inspection and Audit Services for Warehouses and Factories

The ceramic basin, as the core product of the bathroom space, its quality directly affects the user experience and the brand reputation.

Key points for inspection and testing of GPS receiving devices and testing standards Inspection and testing services for factory verification

GPS navigation devices, as important on-board electronic products, their performance reliability and usage safety directly affect the travel experience of user

Shirt inspection methods and inspection testing standards; Inspection and certification services for factories and products

Clothing, as a product that comes into direct contact with the human body, its quality directly affects the consumer experience and the brand reputation.

16-item inspection and testing standards for automotive components Inspection and certification services for goods and factories

As the leader in the global automotive industry, the Volkswagen Group has established an industry-leading and rigorous quality control system for components.

The inspection methods and standards for inflatable toys

Inflatable toys, as a popular category of children's toys, their quality and safety directly affect the health and safety of children.

The inspection contents and selection methods for pillows

As an essential sleep accessory, the quality of pillows directly affects the sleep health and usage experience of consumers.

Introduction to the Inspection Standards for Electric Oven Products Inspection and Certification Services for Warehousing and Factory Audits

The electric oven, as a common kitchen appliance, its quality directly affects the safety and experience of users.

Fabric inspection standards and inspection methods, factory inspection and verification, logistics service inspection

Textiles, as the most common product category in daily life, their quality directly affects the user experience and brand reputation of consumers.

Home appliance inspection process? Classification of home appliances Inspection and factory inspection services

The safety performance of household appliances is the core indicator of product quality and is directly related to the personal safety of consumers.

Issues related to wires that need to be paid attention to during the inspection of electrical appliances

Wires, as the "bloodline" of electrical appliances, their quality directly affects the safety and performance reliability of the products.

The on-site inspection methods and inspection standards for barbecue grills

Barbecue grills, as popular products for outdoor cooking and family gatherings, their safety, functionality and durability directly affect the user experience.

Sleeping bag inspection methods and testing standards

Sleeping bags, as the core equipment for outdoor activities and camping trips, their quality directly affects the comfort level and safety of users.

Standard and method for inspection and testing of protective clothing, as well as inspection and verification methods for factories and certification services

The craftsmanship quality, fabric quality and detail treatment of the jacket directly affect the brand image and the consumer experience.

手持式草地边缘电动修理器的验货方法 验货验厂检验认证服务

手持式草坪及草地边缘电动修剪器是欧美市场重要的园林工具,其操作安全性、电机性能及切割效率直接关系到用户体验与品牌声誉。对于采购商、品牌方及质检专业人员而言,构建全面的供应链质量管理体系

On-site inspection standards and inspection methods for DVD players, as well as factory inspection and verification services

The media era has arrived, yet DVD players still hold a significant position in specialized markets such as in-car entertainment and home theaters.

电动修枝机现场验货的检验检测方法 验厂验货检验服务

电动修枝机作为园林工具和经济作物管理的重要设备,其性能可靠性、操作安全性及耐久性直接关系到用户效率与人身安全。对于采购商、品牌方及质检专业人员而言,构建全面的供应链质量管理体系,

家用机顶盒的验货项目及检测方法 验厂验货检验认证服务

随着数字电视与网络电视的快速发展,机顶盒(Set-Top Box, STB)已成为家庭娱乐的核心设备。其性能稳定性、功能完备性及使用安全性直接关系到用户体验与品牌口碑。对于采购商、品牌方及质检专业人员而言,构建全面的供应链质量管理体系

打火机的检验检测标准和验货方法 验货验厂检验认证服务

打火机作为日常常用品,其质量与安全性直接关系到消费者使用体验与人身安全。对于采购商、品牌方及质检专业人员而言,构建全面的供应链质量管理体系,通过严格的验厂(Factory Audit) 与出货检验(Pre-shipment Inspection, PSI) 至关重要。

家庭音响的测试及检验 验货验厂检验认证服务

随着家庭娱乐需求的升级,家庭音响系统已成为提升生活品质的重要产品。其质量优劣直接关系到用户体验和品牌声誉。对于采购商、品牌方及质检工程师而言,建立一套科学的验厂(Factory Audit) 和验货(Product Inspection) 体系至关重要。

蜡烛的验货方法和检验规则介绍 验货验厂检验认证服务

在电力照明高度普及的今天,蜡烛作为应急照明与氛围营造的重要产品,其质量依然不容忽视。蜡烛的燃烧安全性、稳定性及环保性直接关系到消费者体验与品牌声誉。对于采购商、品牌方及质检人员而言,建立专业的供应链质量管理体系

蚕丝被的检验检测方法以及注意事项 验货验厂检验认证服务

现在的生活节奏越来越快,工作的人们每天早出晚归,高效的时间运用非常重要。睡眠是舒缓压力的最佳途径,但是许多白领工作压力大,晚上睡得又晚,经常翻来覆去无法入睡,从而影响第二天的工作。床被的舒适度在一定程度上也影响了睡眠质量

汽车座椅检测检验标准和验货方法 验货验厂检验认证服务

汽车座椅作为驾乘人员与车辆直接接触最频繁的部件,其舒适性、功能性与安全性直接影响驾驶体验和乘坐品质。因此,在汽车座椅的生产与采购过程中,严格的验厂和验货流程至关重要。

Loading supervision requirements, processes and precautions, inspection, factory inspection, inspection and certification services

Loading supervision is the final step before product shipment and a crucial quality control step to ensure that goods meet customer requirements and arrive safely at their destination. As an inspector, mastering standardized loading supervision procedures and inspection standards is crucial to preventing cargo damage and reducing customer complaints.

How to inspect plush toys? Plush toy quality inspection standards, factory inspection, and services

There are many types of toy products, covering a wide range of fields. Common ones include children's toys, baby toys, plush toys, educational toys, electric toys, wooden toys, plastic toys, metal toys, paper toys and outdoor sports toys. In the inspection and quality control work, we usually divide them into two categories for systematic management.

How to inspect a mattress? Mattress inspection methods and key points Inspection, factory inspection, inspection and certification services

A comfortable mattress is crucial for improving sleep quality. Mattresses on the market are made of a variety of materials, such as palm, rubber, spring, latex, etc., and different materials suit the needs of different people. As an inspector, you need to implement a systematic inspection process when inspecting various mattresses, and focus on common defects and compliance requirements. So, what items should be covered in mattress inspection?

Silk quilt inspection and testing methods and purchasing tips Inspection and factory inspection services

The comfort of bedding largely determines sleep quality. Silk quilts are highly sought after for their softness, breathability, and skin-friendly comfort. This article will systematically explain silk quilt inspection methods, quality standards, and purchasing tips to help you choose silk quilts with greater professionalism and confidence.

How to inspect car seat cushions? Introduction to car seat cushion quality inspection standards and inspection methods Factory inspection and inspection services

Nowadays, almost every family owns a car, making travel convenient. Among essential car accessories, car seat cushions are of paramount importance. While some leather seats don't require cushions, many fabric seats require them for protection from stains and for greater comfort. How do you inspect car seat cushions?

Refrigerator inspection and key knowledge inspection, factory inspection, inspection and certification services

Many functional kitchen appliances have brought a lot of convenience to our lives. For example, the invention of refrigerators has made it possible to keep many ingredients fresh. Refrigerators are widely used and are indispensable in daily life. What should we pay special attention to when inspecting refrigerators? What are the key points when inspecting?

Inspection and testing of bicycle parts, factory inspection services

Bicycles are no strangers to us. From the Phoenix and Forever bikes we used to ride in our youth to the ubiquitous public bikes of today, they've brought a lot of convenience to our daily lives. Bicycles are made up of various parts. Here's what inspectors need to pay attention to when inspecting bicycle parts, and what specific tests are required!

How to detect and remove odor from textiles? Inspection and certification services

Textile odors are directly related to product safety and market acceptance, and are a key sensory inspection component in product inspections, factory audits, and product quality control. Common odors include musty odors, high-boiling-range petroleum odors (such as gasoline and kerosene), fishy odors, and aromatic hydrocarbon odors. Their sources are complex, involving multiple processes, including raw materials, production processes, storage, and transportation.

Inspection items and methods for fans, inspection, factory inspection, certification and other services

A suitable temperature will make people feel comfortable. In the hot summer, fans should be a very good cooling helper, especially for students. Buying a suitable fan can make you feel cool. When inspectors inspect fans, what kind of inspections will they conduct and what test items are required?

How can you safely pass the numerous checkpoints of toy testing?

As toys are items that children come into contact with, safety must be ensured from design to production. All products that can pass the test mentioned in this article are qualified in themselves. The Chinese toy standard GB 6675, the US toy standard ASTM F963 and the EU toy standard EN71 all use the age limit of 14 years and below as the standard for children.

Inspection photography skills and requirements Inspection, factory inspection, inspection and certification services

During product inspections, factory inspections, and other types of product testing, video documentation is not only an essential component of the work but also a direct reflection of the report's credibility and professionalism. High-quality photos clearly demonstrate product status, defect details, and the on-site environment, providing a key basis for quality assessments and effectively avoiding customer disputes and complaints.

Inspection standards and methods for vacuum cleaner products, factory inspection, inspection and certification services

Household cleaning products, such as vacuum cleaners and robot vacuums, have become indispensable appliances in modern households. Their quality directly impacts user experience and brand reputation. As a QC inspector, you must systematically understand key test items and operating procedures during the inspection, factory inspection, and final delivery of these products to ensure they meet technical standards and customer requirements.

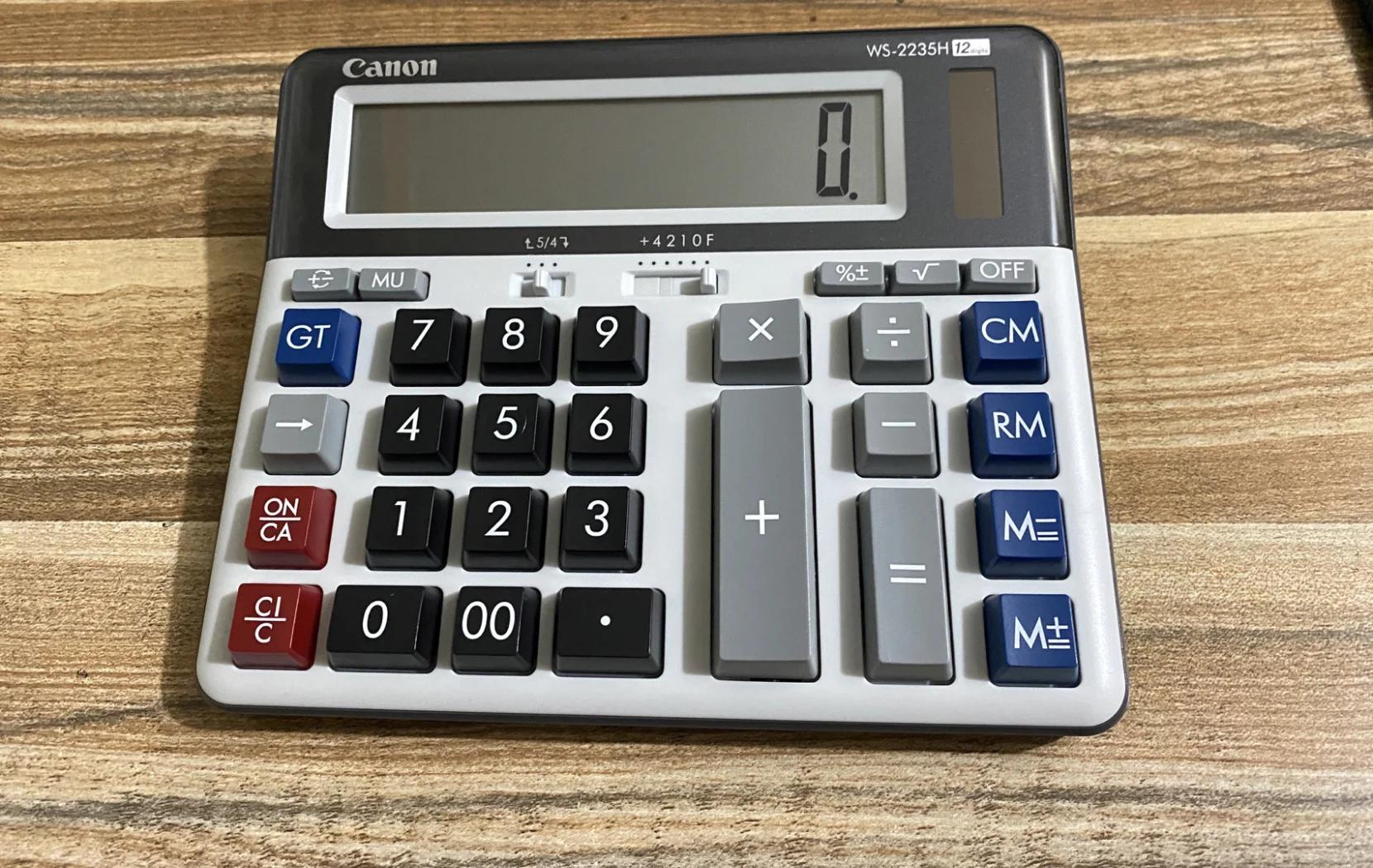

What are the items for calculator inspection? Read on to understand the inspection, factory inspection, inspection and certification services.

As an essential component of our quality control (QC) process, calculator product inspection involves comprehensive checks on packaging, safety, appearance, functionality, and performance. The following detailed inspection specifications, based on industry standards and factory inspection requirements, ensure that products meet customer specifications and quality expectations.

Bathroom and shower room inspection methods and test contents, factory inspection, inspection and certification services

Bathroom products are a core component of home renovations, and their quality directly impacts the user's comfort and safety in daily use. Leakage, cracking, or functional failure can cause significant inconvenience. Therefore, implementing a systematic and rigorous inspection process for bathroom and shower room products during the inspection process is crucial to ensuring overall quality.

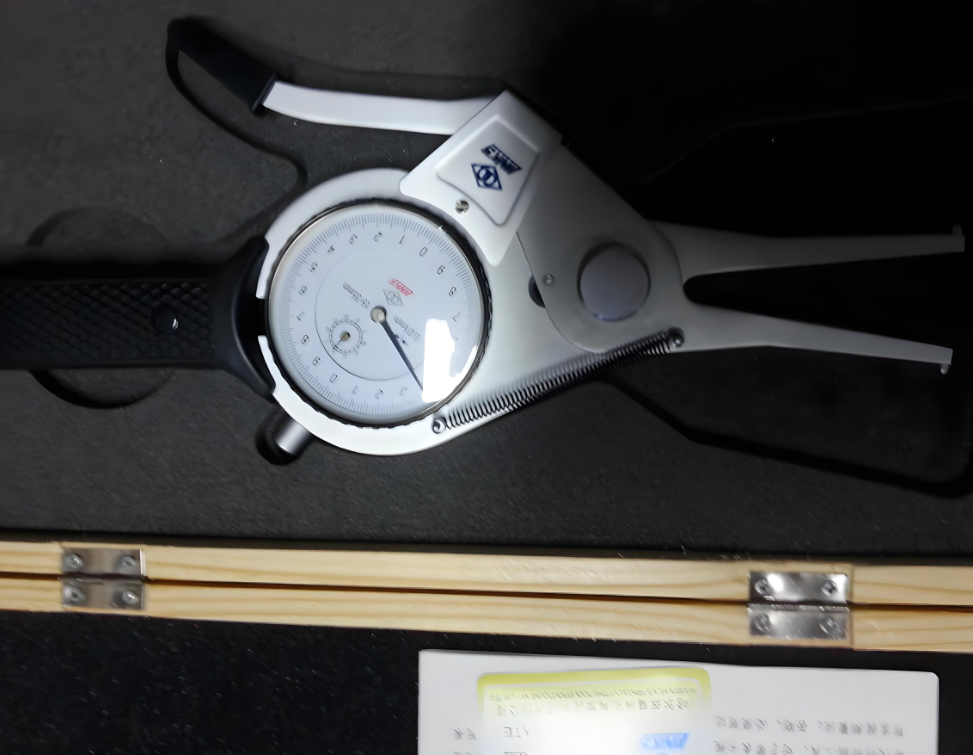

How to use the height gauge? Provide inspection and factory certification services

As a quality control technician, you need to use a lot of tools during the inspection process. If you want to be a qualified or even excellent inspector, you must be familiar with the use of each tool. Today, I will talk to you about the use of one of the most common tools - the dial height gauge.

How to use the inspector's dial indicator correctly Inspection, factory inspection, inspection and certification services

For every QC, inspection tools are a valuable aid. Besides commonly used tools, it's also important to master the use of more precise tools with narrower applications. While these tools may not be used all the time, it's always good to have more skills, right? Today, Encyclopedia presents how to use a dial indicator. If you find it useful, save it!

Inspection standards and methods for inspector scales, factory inspections, and certification services

Scales are familiar to everyone. They are very practical for measuring weight in daily life. Common ones include electronic kitchen scales, electronic body scales, and mechanical body scales. So, what are the key points to check when inspecting and testing scales? What tests should be performed? I hope these contents will be helpful to you!

On-site inspection methods and test contents of heaters by inspectors, factory inspections, and certification services

As a seasonal heating device, the quality of the fan heater is directly related to the safety of users' lives and property. As an inspector, you must fully understand the inspection standards and testing methods of the fan heater to ensure that the product meets international safety standards and customer requirements. This article will systematically introduce the inspection process of the fan heater from the perspective of professional inspection.

How to inspect wireless Bluetooth headsets through China Inspection and Quarantine Inspection, Factory Certification, and Testing? Headphone inspection standards and methods

Wearing headphones and walking on the street, I feel as if I am isolated from the hustle and bustle of the world. A few years ago, wired headphones were still the mainstream. Now, with the rapid development of technology, wireless Bluetooth headphones have quickly taken over the market with their convenient user experience and strong sense of technology.

【Inspector Encyclopedia】Introduction to Sunglasses Testing Methods and Standards, China Inspection and Quarantine Inspection, Factory Inspection, Certification and Testing

Sunglasses are a kind of vision protection product to prevent damage to human eyes caused by strong stimulation of sunlight. They are also a special decoration that is fashionable or reflects personal style. Sunglasses are popular for their protective and decorative functions, but since they directly affect personal safety, their quality requirements are particularly high.

【Inspector Encyclopedia】Introduction to cosmetics inspection standards and basic knowledge Provide professional inspection, factory inspection, certification and audit services

As specialized products applied directly to the human body, cosmetics' quality and safety are directly linked to consumer health. Cosmetics inspection is not limited to laboratory testing; it requires a comprehensive quality control system, from raw material acceptance to finished product shipment. This article systematically introduces the professional knowledge of cosmetics inspection, providing practical guidance for inspectors, quality control personnel, and related professionals.

[Inspector Encyclopedia] Introduction to watch inspection methods and providing professional inspection, factory inspection, certification and audit services

High-end watches are not only precise timekeeping instruments, but also luxury goods that symbolize taste and status. Products from well-known brands such as Patek Philippe, Breguet, and IWC are expensive, so strict standards and professional inspection procedures must be followed during the inspection process. This article will detail the specific methods and precautions for watch inspection.

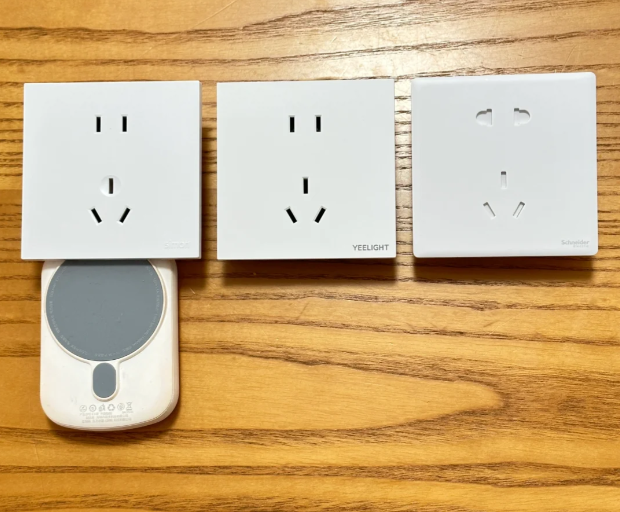

[Inspector Encyclopedia] Common quality issues of plugs and sockets. Provide professional inspection, factory inspection, certification and audit services

Despite their compact size, plugs and sockets are crucial to electrical safety in every household. They are essential components for everything from daily use to industrial production and high-tech applications. According to public security statistics, substandard plug and socket quality has become a major cause of electrical fires in recent years.